This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Exhaust Transfer Tube Idler Shaft Thermostat (Part #5262661) is a component designed to regulate the flow of exhaust gases within the exhaust system of heavy-duty trucks. Its purpose is to optimize the exhaust management system, ensuring efficient operation and contributing to overall engine performance. This thermostat is significant in maintaining the balance of the exhaust system, which is essential for the truck’s efficiency and longevity.

Basic Concepts

Understanding the Exhaust Transfer Tube Idler Shaft Thermostat requires familiarity with its components and functionality. This thermostat is part of the exhaust system, which includes the exhaust manifold, turbocharger, exhaust transfer tube, and muffler. The thermostat is integrated into the exhaust transfer tube and operates by controlling the flow of exhaust gases. It consists of a housing, a thermostatic element, and an idler shaft. The thermostatic element responds to temperature changes, adjusting the position of the idler shaft to regulate exhaust flow 3.

Purpose and Role

The primary purpose of the Exhaust Transfer Tube Idler Shaft Thermostat is to manage the temperature and flow of exhaust gases. By doing so, it plays a role in enhancing the efficiency of the exhaust system and supporting optimal engine performance. The thermostat helps in reducing backpressure, which can improve fuel efficiency and reduce emissions. Additionally, it aids in maintaining consistent exhaust gas temperatures, which is beneficial for the durability and performance of the turbocharger and other exhaust components 4.

Key Features

The Exhaust Transfer Tube Idler Shaft Thermostat is characterized by its robust design and the materials used in its construction. It is typically made from high-quality metals that can withstand the high temperatures and pressures of the exhaust system. The thermostatic element is designed to be responsive to temperature changes, ensuring precise control over exhaust flow. Additionally, the idler shaft is engineered to operate smoothly, minimizing wear and ensuring reliable performance over time 5.

Benefits

Using the Exhaust Transfer Tube Idler Shaft Thermostat offers several benefits. It contributes to improved exhaust flow, which can enhance engine efficiency and performance. By regulating exhaust gas temperatures, it helps in reducing thermal stress on exhaust components, potentially leading to longer component life. Fleet operators may also experience cost savings due to improved fuel efficiency and reduced maintenance requirements 1.

Installation and Integration

Proper installation of the Exhaust Transfer Tube Idler Shaft Thermostat is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure it is securely fitted within the exhaust transfer tube. Any necessary modifications or adjustments to the exhaust system should be made to accommodate the thermostat without compromising the system’s integrity. Careful attention to sealing and connections is also important to prevent exhaust leaks 2.

Maintenance and Troubleshooting

Maintaining the Exhaust Transfer Tube Idler Shaft Thermostat involves regular inspection and cleaning to ensure it operates efficiently. It is important to check for any signs of wear or damage to the thermostatic element and idler shaft. Troubleshooting common issues may involve checking for proper thermostat operation, ensuring there are no obstructions in the exhaust path, and verifying that all connections are secure. Regular maintenance can help in identifying potential problems early, ensuring the thermostat continues to function effectively 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a strong reputation in the automotive industry, Cummins is committed to delivering high-quality components that meet the demanding requirements of heavy-duty applications. The company’s focus on quality, performance, and reliability is evident in its extensive range of automotive components, including the Exhaust Transfer Tube Idler Shaft Thermostat.

Compatibility of Part 5262661 with Cummins Engines

The part 5262661, which is a Thermostat Exhaust Transfer Tube Idler Shaft manufactured by Cummins, is designed to fit a variety of Cummins engines. Here is a detailed look at its compatibility with the specified engines:

ISF2.8 CM2220 Engines

- ISF2.8 CM2220 F117

- ISF2.8 CM2220 F129

The Thermostat Exhaust Transfer Tube Idler Shaft part 5262661 is compatible with both ISF2.8 CM2220 F117 and ISF2.8 CM2220 F129 engines. These engines are part of the Cummins ISF2.8 series, which are known for their reliability and efficiency in various applications.

QSF2.8 CM2880 Engines

- QSF2.8 CM2880 F104

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F108

- QSF2.8 CM2880 F114

The part 5262661 is also compatible with the QSF2.8 CM2880 series engines, including F104, F105, F108, and F114 variants. These engines are part of the Cummins QSF2.8 series, which are designed for heavy-duty applications and offer robust performance.

R2.8 CM2220 Engine

- R2.8 CM2220 R101B

Lastly, the Thermostat Exhaust Transfer Tube Idler Shaft part 5262661 fits the R2.8 CM2220 R101B engine. This engine is part of the Cummins R2.8 series, which is engineered for medium-duty applications, providing a balance of power and efficiency.

By ensuring compatibility with these engines, the part 5262661 helps maintain the performance and longevity of the engines it is installed in.

Role of Part 5262661 Thermostat, Exhaust Transfer Tube, Idler Shaft in Engine Systems

The thermostat, exhaust transfer tube, idler shaft (part 5262661) is an integral component in the orchestration of various engine systems, ensuring optimal performance and efficiency.

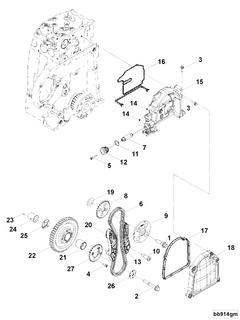

Integration with Housing

The housing serves as the protective enclosure for many engine components, including the thermostat. The thermostat, a temperature-sensitive valve, is positioned within the housing to regulate the flow of coolant between the engine and the radiator. This regulation is vital for maintaining the engine’s operating temperature, which in turn affects combustion efficiency and reduces wear on engine components. The exhaust transfer tube, part of this assembly, facilitates the smooth transfer of exhaust gases, minimizing backpressure and enhancing engine performance. The idler shaft, although primarily associated with the timing mechanism, interacts with the housing to ensure precise alignment and operation of the exhaust transfer tube 4.

Interaction with Rear Gear

The rear gear, a component of the engine’s transmission system, works in conjunction with the idler shaft to maintain the timing of the engine’s valves. The idler shaft, often overlooked, plays a significant role in this process by providing the necessary tension and support to the timing belt or chain. This ensures that the rear gear operates in harmony with the engine’s crankshaft and camshaft, allowing for efficient power transmission and smooth engine operation. The exhaust transfer tube, by efficiently routing exhaust gases away from the engine, reduces the likelihood of interference with the rear gear and other transmission components, thereby contributing to the overall reliability and performance of the engine system 5.

Conclusion

The Exhaust Transfer Tube Idler Shaft Thermostat (Part #5262661) is a critical component in the exhaust management system of heavy-duty trucks. Its role in regulating exhaust gas flow and temperature contributes to improved engine efficiency, performance, and longevity. Proper installation, maintenance, and understanding of its functionality are essential for maximizing the benefits of this Cummins part.

-

Reif, Konrad, Ed. Diesel Engine Management Systems and Components. Springer Vieweg, 2014.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 6314863.

↩ -

Halderman, James D. Automotive Principles: Diagnosis and Service. Prentice Hall, 2012.

↩ ↩ -

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ ↩ -

Reif, Konrad, Ed. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.