5285574

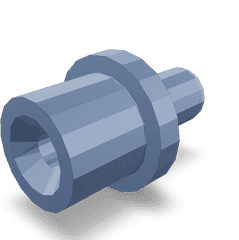

Idler Shaft

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5285574 Idler Shaft is a component designed for use in heavy-duty trucks. It serves a specific function within the engine’s accessory drive system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and operation is key to maintaining and optimizing the performance of heavy-duty trucks.

Basic Concepts of Idler Shafts

An idler shaft is a component used in drivetrains to maintain proper belt tension and alignment. It does not directly drive any accessories but plays a vital role in ensuring that belts run smoothly and efficiently by adjusting their path and tension. This is crucial for the longevity and performance of the driven components, such as alternators, water pumps, and air conditioning compressors 1.

Purpose of the Cummins 5285574 Idler Shaft

This Cummins part is integral to the engine’s accessory drive system. It helps in maintaining the correct tension and alignment of the belts that drive various engine accessories. By doing so, it ensures that these accessories operate efficiently and with minimal wear, contributing to the overall performance and reliability of the truck.

Key Features

The 5285574 is constructed from high-quality materials, ensuring durability and resistance to wear. Its design includes precision-machined surfaces and high-quality bearings, which contribute to smooth operation and longevity. Additionally, the shaft is engineered to withstand the high stresses and temperatures encountered in heavy-duty truck applications 2.

Benefits

Utilizing this part offers several advantages. It contributes to improved efficiency by ensuring optimal belt tension and alignment, which reduces the wear on other components. This leads to enhanced reliability and potentially lower maintenance costs over the vehicle’s lifespan.

Installation and Integration

Proper installation of the 5285574 is crucial for its effective operation. It should be aligned correctly within the engine system to ensure that belts run true and without excessive tension. Preparations may include cleaning the installation area and ensuring that all mating surfaces are free of debris.

Maintenance and Troubleshooting

Routine maintenance of the 5285574 involves checking for proper belt tension and alignment, as well as inspecting the shaft and bearings for signs of wear or damage. Common troubleshooting tips include addressing unusual noises or vibrations, which may indicate issues with the shaft or its bearings.

Performance Enhancements

The 5285574 contributes to overall engine performance by ensuring that the accessory drive system operates efficiently. This can lead to improvements in power delivery and efficiency, as accessories are able to function optimally without placing undue stress on the engine.

Cummins Overview

Cummins Inc. is a renowned manufacturer of diesel engines and related components, with a long-standing reputation for quality and reliability. The company’s commitment to innovation and excellence is reflected in its products, including the 5285574, which is designed to meet the demanding requirements of heavy-duty truck applications 3.

Idler Shaft Part 5285574 in Cummins Engines

The Idler Shaft part 5285574 is a critical component in several Cummins engine models, ensuring smooth operation and efficiency. This part is designed to work seamlessly with the ISL G CM2180, QSL9 CM2250, and QSL9 CM2350 L102 engines.

ISL G CM2180

In the ISL G CM2180 engine, the Idler Shaft part 5285574 plays a pivotal role in maintaining the balance and alignment of the engine’s internal components. It helps in reducing friction and wear, contributing to the longevity and reliability of the engine.

QSL9 CM2250 and QSL9 CM2350 L102

For the QSL9 CM2250 and QSL9 CM2350 L102 engines, the Idler Shaft part 5285574 is equally essential. It ensures that the engine’s timing and synchronization are maintained, which is crucial for the efficient operation of these high-performance engines. The design of this part allows it to handle the specific demands and stresses of these models, providing a stable and reliable performance.

The integration of the Idler Shaft part 5285574 in these engines highlights Cummins’ commitment to quality and precision in engine manufacturing. This part is engineered to fit perfectly within the engine’s architecture, ensuring optimal performance and durability.

Role of Part 5285574 Idler Shaft in Engine Systems

The idler shaft, specifically part 5285574, is an integral component in the operation of various engine systems, particularly in the context of alternator mounting and support. This shaft facilitates the smooth rotation of the alternator, ensuring that it maintains the correct alignment and tension within the engine’s accessory drive system.

In the alternator mounting system, the idler shaft works in conjunction with the alternator, tensioner, and various pulleys. It helps to maintain the proper belt tension, which is essential for the efficient transfer of power from the engine to the alternator. This ensures that the alternator can generate the necessary electrical power to charge the battery and power the vehicle’s electrical systems.

Additionally, the idler shaft provides support to the alternator by helping to stabilize its position within the engine compartment. This support is vital for the alternator’s durability and performance, as it reduces the stress and wear on the alternator’s mounting points and internal components.

Overall, the idler shaft plays a significant role in the reliable operation of the alternator within the engine system, contributing to the vehicle’s overall performance and efficiency.

Conclusion

The Cummins 5285574 Idler Shaft is a vital component in the accessory drive system of heavy-duty trucks, ensuring the efficient operation of engine accessories through proper belt tension and alignment. Its high-quality construction and precise engineering contribute to the durability and reliability of the vehicle. Proper maintenance and installation are essential for maximizing its benefits, which include improved engine performance and reduced maintenance costs.

-

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.