This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

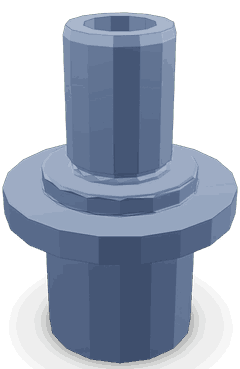

The Cummins 5303409 Idler Shaft is a component designed for use in heavy-duty trucks. It serves a specific function within the truck’s engine or transmission system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is key to maintaining the optimal performance of heavy-duty trucks.

Basic Concepts of Idler Shafts

An idler shaft is a mechanical component used in various systems to change the direction of a rotating force or to provide support and tension to a belt or chain. In the context of a truck’s engine or transmission, the idler shaft operates by interacting with gears, belts, or chains to ensure smooth operation and efficient power transmission. Its role is to maintain proper alignment and tension, which is crucial for the longevity and performance of the mechanical system 1.

Purpose of the 5303409 Idler Shaft

The Cummins 5303409 Idler Shaft is specifically engineered to support the operation of heavy-duty trucks. It plays a role in the engine or transmission system by maintaining the correct tension and alignment of components. This ensures that power is transmitted efficiently from the engine to the drivetrain, contributing to the truck’s overall functionality and performance. Its interaction with other components is designed to reduce wear and enhance the reliability of the truck’s mechanical systems 2.

Key Features

The Cummins 5303409 Idler Shaft is characterized by several key features that enhance its performance and durability. These include a robust material composition, typically involving high-strength alloys, which provide resistance to wear and fatigue. The design elements of the shaft are tailored to ensure precise alignment and smooth operation within the truck’s engine or transmission. Additionally, any unique characteristics, such as specialized coatings or treatments, further contribute to its longevity and efficiency 3.

Benefits

The advantages provided by the Cummins 5303409 Idler Shaft include improved efficiency in power transmission, reduced wear on associated components, and enhanced reliability of the truck’s mechanical systems. By maintaining proper tension and alignment, it helps to ensure that the engine and transmission operate smoothly, which can lead to better fuel efficiency and reduced maintenance costs over time.

Installation and Integration

Proper installation of the Cummins 5303409 Idler Shaft is crucial for its effective operation. Guidelines for installation include ensuring compatibility with the specific truck model, correct alignment within the engine or transmission system, and securing it in place to prevent movement or misalignment. Attention to these details during installation helps to maximize the performance and longevity of the component.

Troubleshooting Common Issues

Common problems associated with idler shafts, such as noise, vibration, or failure, can often be traced back to issues with alignment, tension, or wear. Diagnostic steps to determine if the Cummins 5303409 Idler Shaft is the source of the issue include inspecting for signs of wear or damage, checking alignment and tension, and listening for abnormal noises during operation. Addressing these issues promptly can help to prevent further damage to the truck’s engine or transmission system.

Maintenance Tips

Routine maintenance practices are important for ensuring the longevity and optimal performance of the Cummins 5303409 Idler Shaft. Recommendations include regular inspection intervals to check for signs of wear or damage, ensuring proper lubrication to reduce friction and wear, and addressing any issues promptly to prevent further damage. Following these maintenance tips can help to extend the life of the idler shaft and maintain the efficiency of the truck’s engine or transmission system.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history of innovation and a strong reputation in the automotive and heavy-duty truck industries, Cummins is known for producing high-quality components that enhance the performance and reliability of vehicles. The company’s commitment to excellence is reflected in its product range, which includes a variety of parts designed to meet the demanding requirements of heavy-duty applications.

Idler Shaft (Part 5303409) Compatibility with Cummins Engines

The Idler Shaft, identified by part number 5303409, is a critical component in the operation of certain Cummins engines. This part is designed to work seamlessly with specific engine models, ensuring optimal performance and longevity. Below is a detailed look at the compatibility of this idler shaft with various Cummins engines.

QSB6.7 CM850 (CM2850) Engine

The Idler Shaft 5303409 is engineered to fit the QSB6.7 CM850 (CM2850) engine. This engine is known for its robust performance and reliability, often used in heavy-duty applications. The idler shaft plays a crucial role in maintaining the timing and balance of the engine’s internal components, ensuring smooth operation and reducing wear and tear.

QSB7 CM2880 B117 Engine

Similarly, the Idler Shaft 5303409 is also compatible with the QSB7 CM2880 B117 engine. This engine variant is designed for high-performance applications, providing substantial power and efficiency. The idler shaft in this engine setup is essential for the proper functioning of the engine’s belt-driven accessories, such as the alternator and water pump, ensuring they operate at the correct speed and alignment.

Grouping Compatibility

Both the QSB6.7 CM850 (CM2850) and QSB7 CM2880 B117 engines belong to the Cummins QSB series, which is renowned for its durability and performance in various industrial and commercial applications. The Idler Shaft 5303409 is specifically designed to meet the demands of these engines, providing a reliable and efficient solution for maintaining the engine’s operational integrity.

By ensuring that the idler shaft is correctly installed and maintained, operators can expect enhanced engine performance, reduced downtime, and extended service life for their equipment.

Role of Part 5303409 Idler Shaft in Engine Systems

The 5303409 Idler Shaft is an integral component in the accessory drive system of an engine, facilitating the efficient operation of various engine-driven accessories. Within the accessory drive kit, the idler shaft works in conjunction with the drive belt to maintain proper tension and alignment. This ensures that the belt remains securely in place and operates smoothly, minimizing the risk of slippage or misalignment that could lead to decreased performance or damage to the belt.

In systems where the water pump is driven by the accessory belt, the idler shaft plays a significant role. By maintaining the correct tension on the belt, it ensures that the water pump receives consistent power. This consistent power transfer is essential for the water pump to circulate coolant effectively through the engine, helping to maintain optimal operating temperatures and prevent overheating.

Additionally, the idler shaft interacts with the idler pulley, which is another component designed to keep the belt properly tensioned and aligned. The idler pulley can adjust its position to accommodate changes in belt length or wear, and the idler shaft supports this function by providing a stable axis of rotation. This collaboration between the idler shaft and idler pulley enhances the durability and reliability of the accessory drive system, ensuring that all connected components, such as the alternator and power steering pump, receive the necessary power to function correctly.

Conclusion

The Cummins 5303409 Idler Shaft is a vital component in the maintenance and operation of heavy-duty trucks, particularly those equipped with Cummins engines. Its role in maintaining tension and alignment within the engine or transmission system contributes significantly to the efficiency, reliability, and longevity of the vehicle. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential practices to ensure the optimal performance of this part. By understanding and adhering to these guidelines, operators can enhance the overall functionality of their trucks and reduce the likelihood of costly repairs or downtime.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.