This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

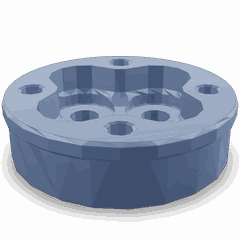

The Crankshaft Flange 5336431 is a component manufactured by Cummins, a well-established name in the commercial truck engine industry. This flange plays a significant role in the functionality of truck engines, ensuring efficient operation and reliability. Understanding its purpose and features can provide valuable insights into engine mechanics and maintenance.

Basic Concepts

A crankshaft flange is a component that attaches to the end of a crankshaft. Its primary function is to provide a mounting point for accessories such as the flywheel, vibration damper, or harmonic balancer. The flange interfaces with these components, allowing them to be securely fastened to the crankshaft. This connection is vital for the transmission of rotational force from the engine to the drivetrain and for the operation of various engine accessories 1.

Purpose of Crankshaft Flange 5336431

The Crankshaft Flange 5336431 is designed to play a specific role in the operation of a truck engine. It connects to the crankshaft, providing a stable platform for the attachment of the flywheel and other components. This flange ensures that the rotational forces generated by the engine are efficiently transmitted to the drivetrain. Additionally, it helps in balancing the crankshaft, reducing vibrations, and enhancing the overall smoothness of engine operation 2.

Key Features

The Crankshaft Flange 5336431 is constructed with high-quality materials to ensure durability and performance. Its design includes precise machining to ensure a perfect fit with the crankshaft and other connected components. The flange may feature specific bolt patterns and surface treatments to enhance its strength and resistance to wear. These features contribute to the flange’s ability to withstand the high stresses and temperatures encountered in a commercial truck engine 3.

Benefits

The use of the Crankshaft Flange 5336431 offers several advantages. It contributes to improved engine efficiency by ensuring a secure and stable connection between the crankshaft and the flywheel. This results in more effective transmission of power and reduced energy loss. Additionally, the flange’s design helps in minimizing vibrations, leading to a smoother engine operation. Its robust construction enhances the reliability and longevity of the engine components it supports 4.

Installation and Compatibility

Proper installation of the Crankshaft Flange 5336431 is crucial for its effective function. It should be aligned correctly with the crankshaft and secured with the appropriate torque specifications to ensure a tight and stable fit. Compatibility with specific engine models and configurations should be verified to ensure optimal performance and reliability. Following manufacturer guidelines during installation will help prevent issues and ensure the flange operates as intended.

Maintenance and Troubleshooting

Regular maintenance of the Crankshaft Flange 5336431 is important to ensure its longevity and optimal performance. This includes checking for signs of wear or damage, ensuring all bolts are tightened to the correct specifications, and verifying that the flange remains securely attached to the crankshaft. Common issues may include loose connections, wear on the flange surface, or damage to the bolt holes. Addressing these issues promptly can prevent more significant problems and ensure the engine continues to operate efficiently.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality, reliability, and innovation in the commercial truck industry. Their product range includes a variety of engines and components designed to meet the demanding requirements of commercial applications, ensuring high performance and durability.

Cummins Crankshaft Flange Part 5336431 Compatibility

The Cummins crankshaft flange part 5336431 is a critical component designed to fit seamlessly with several of Cummins’ engine models. This part is essential for the proper assembly and operation of the engine, ensuring that the crankshaft is securely fastened to the engine block.

ISB3.9 and CM2220 Engines

The ISB3.9 and CM2220 engines are part of Cummins’ lineup of medium-duty diesel engines. These engines are known for their reliability and efficiency, often used in various applications such as trucks, buses, and industrial machinery. The crankshaft flange part 5336431 is specifically engineered to fit these engines, providing a robust connection between the crankshaft and the engine block. This ensures that the engine operates smoothly and efficiently, reducing the risk of mechanical failure.

B107 Engine

The B107 engine is another model in Cummins’ portfolio, designed for heavy-duty applications. This engine is commonly used in large trucks, construction equipment, and other heavy machinery. The crankshaft flange part 5336431 is also compatible with the B107 engine, ensuring that the crankshaft is securely fastened to the engine block. This is crucial for maintaining the integrity of the engine under heavy loads and demanding conditions.

Grouping of Engines

The ISB3.9 and CM2220 engines are often grouped together due to their similar applications and design philosophies. Both engines are medium-duty and are frequently used in commercial and industrial settings. The B107 engine, on the other hand, is typically used in heavy-duty applications, making it suitable for more demanding environments. Despite the differences in their intended use, the crankshaft flange part 5336431 is designed to fit all these engines, ensuring compatibility across Cummins’ engine lineup.

Role of Part 5336431 Crankshaft Flange in Engine Systems

The Part 5336431 Crankshaft Flange is an integral component in the efficient operation of engine systems, particularly in its interaction with the damper and vibration management mechanisms.

Interaction with Damper

The Crankshaft Flange interfaces directly with the damper, which is essential for absorbing torsional vibrations generated by the engine’s operation. This interaction ensures that the damper can effectively mitigate these vibrations, leading to smoother engine performance and reduced wear on connected components. The flange’s precise fit and secure attachment are vital for the damper to function optimally, maintaining the balance and stability of the crankshaft during engine operation.

Vibration Management

In terms of vibration management, the Crankshaft Flange plays a significant role by providing a stable mounting point for various engine components. Its design and material properties are tailored to handle the dynamic forces exerted by the engine, ensuring that vibrations are minimized and controlled. This not only enhances the durability of the engine but also contributes to a more consistent and reliable performance across a range of operating conditions.

The effective integration of the Crankshaft Flange with the damper and vibration control systems underscores its importance in maintaining the overall health and efficiency of the engine.

Conclusion

The Crankshaft Flange 5336431 is a vital component in the operation of Cummins truck engines. Its role in connecting the crankshaft to essential accessories, managing vibrations, and ensuring efficient power transmission highlights its importance in engine mechanics. Proper installation, maintenance, and understanding of its features and benefits are crucial for maintaining engine performance and reliability.

-

Mohamed ElSayed PE, Fundamentals of Integrated Vehicle Realization, SAE International, 2017.

↩ -

Reza N. Jazar, Vehicle Dynamics: Theory and Application, Springer, 2017.

↩ -

Robert Huzij, Angelo Spano, Sean Bennett, Modern Diesel Technology Heavy Equipment Systems, Delmar Cengage Learning, 2014.

↩ -

Richard Stone, Introduction to Internal Combustion Engines, Fourth Edition, Macmillan, 2012.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.