This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

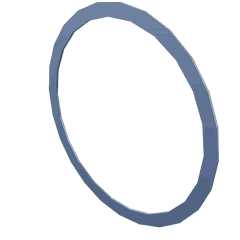

The Cummins 3862677 Shim is a component used in the maintenance and operation of heavy-duty trucks. It serves a specific function within the mechanical systems of Cummins engines, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is key to maintaining optimal performance in heavy-duty truck applications 1.

Basic Concepts of Shims

Shims are thin, often washer-like spacers used in mechanical systems to fill small gaps, adjust clearances, and ensure proper alignment between components. They play a role in maintaining the precise spacing required for the efficient operation of machinery. By addressing clearances and alignments, shims help to reduce wear, prevent excessive friction, and ensure that components function as intended 2.

Purpose of the 3862677 Shim

The 3862677 Shim is designed to play a role in the operation of Cummins engines by providing the necessary clearance and alignment for specific components. It is applied in various mechanical systems within these engines, supporting functions that are vital to the engine’s performance. The shim’s role is to ensure that parts operate within their designed parameters, contributing to the engine’s overall efficiency and longevity 3.

Key Features

The 3862677 Shim is characterized by its material composition, which is selected for durability and precision. Its thickness is carefully calibrated to meet the specific clearance requirements of the engine components it supports. Unique design elements may include surface treatments or specific shapes that enhance its functionality and integration within the engine system 4.

Benefits of Using the 3862677 Shim

Incorporating the 3862677 Shim into engine maintenance routines can lead to improved engine performance, as it helps maintain the precise clearances necessary for optimal operation. It contributes to reduced wear on components by ensuring that parts are properly aligned and spaced. Additionally, the use of this shim can enhance the reliability of the engine, leading to more consistent performance over time 1.

Installation and Usage

Proper installation of the 3862677 Shim involves several steps to ensure it functions correctly. Preparatory steps may include cleaning the area where the shim will be placed and inspecting the components for any damage or irregularities. The tools required for installation will vary depending on the specific application, but they typically include basic hand tools for placement and adjustment. Following best practices during installation, such as ensuring the shim is correctly oriented and securely in place, is important for optimal performance 2.

Troubleshooting Common Issues

Common problems associated with shim usage can include improper clearance or misalignment, which may lead to increased wear or reduced efficiency. Troubleshooting these issues involves checking the shim’s placement and condition, ensuring it is the correct size and material for the application, and making adjustments as necessary to restore proper clearances and alignments 3.

Maintenance Tips

Regular maintenance of the 3862677 Shim includes periodic inspection to check for signs of wear or damage. Cleaning the shim and its surrounding components can help prevent buildup that might affect performance. Replacement should be considered if the shim shows significant wear or if it no longer provides the necessary clearance and alignment for the engine components 4.

Compatibility and Application

The 3862677 Shim is designed for use in specific Cummins engines and truck models. Its application is guided by the manufacturer’s recommendations, ensuring it is used in the correct context to achieve the desired performance and reliability outcomes 1.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, related technologies, and services. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the heavy-duty truck industry. The company’s product range includes engines, filtration, emissions solutions, and more, all designed to meet the demanding requirements of commercial vehicle applications 2.

Shim Part 3862677 Compatibility with Cummins Engines

The Shim part 3862677, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is essential for ensuring proper engine alignment and performance. Here is a detailed look at its compatibility across different engine models:

ISM Series Engines

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

The ISM series engines, including the ISM CM570, ISM CM570/870, ISM CM876, and ISM11 CM876 SN, are equipped with the Shim part 3862677. This part is crucial for maintaining the correct clearance and alignment between engine components, ensuring optimal performance and longevity.

L10 Series Engines

- L10 CELECT

- L10 MECHANICAL

The L10 series engines, both the L10 CELECT and L10 MECHANICAL variants, also utilize the Shim part 3862677. This shim ensures that the engine components are properly aligned, which is vital for the smooth operation of these engines.

M11 Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

The M11 series engines, including the M11 CELECT, M11 CELECT PLUS, and M11 MECHANICAL, are compatible with the Shim part 3862677. This part plays a key role in maintaining the precise alignment of the engine’s internal components, contributing to the overall efficiency and reliability of the engine.

QSM11 Series Engine

- QSM11 CM570

The QSM11 CM570 engine also requires the Shim part 3862677. This shim is essential for ensuring that the engine components are correctly aligned, which is crucial for the engine’s performance and durability.

By using the Shim part 3862677, these Cummins engines can maintain the necessary clearance and alignment, ensuring optimal performance and longevity 3.

Role of Part 3862677 Shim in Engine Systems

The 3862677 Shim is integral to the proper functioning of various engine components, ensuring optimal performance and longevity. In the context of an accessory drive gear, the shim plays a role in maintaining the correct clearance and alignment, which is essential for the efficient transfer of power from the engine to the accessories.

When it comes to the flange repair kit, the shim is used to ensure that the flange is properly aligned and secured, preventing any potential leaks or misalignments that could lead to system failure.

In the flywheel top-level assembly housing, the shim is employed to maintain the precise spacing between the flywheel and the housing. This is vital for the smooth operation of the flywheel, which is responsible for storing rotational energy and smoothing out the power delivery from the engine.

For the gear repair kit, the shim ensures that the gears are correctly spaced and aligned, which is essential for the efficient transmission of power within the engine system.

In the housing and flywheel assembly, the shim is used to maintain the correct clearance between the flywheel and the housing, ensuring that the flywheel operates smoothly and efficiently.

In the housing and flywheel repto (rear power take-off) assembly, the shim ensures that the flywheel is correctly aligned with the repto, which is essential for the efficient transfer of power to the rear-mounted accessories or implements.

Lastly, in the housing and flywheel rpto (remote power take-off) assembly, the shim is used to maintain the correct clearance and alignment between the flywheel and the rpto, ensuring that power is efficiently transferred to the remote-mounted accessories or implements 4.

Conclusion

The Cummins 3862677 Shim plays a crucial role in maintaining the efficiency and reliability of Cummins engines by ensuring proper clearance and alignment of engine components. Its application across various engine models and systems highlights its importance in the maintenance and operation of heavy-duty trucks. Regular maintenance and proper installation of this shim are essential for achieving optimal engine performance and longevity.

-

Giles, Tim. Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning, 2019.

↩ ↩ ↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ ↩ ↩ -

Fijalkowski, BT. Automotive Mechatronics Operational and Practical Issues Volume 1. Springer, 2011.

↩ ↩ ↩ -

Ling, Frederick F. The Automotive Body. Springer Science, 2011.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.