This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3915128 Shim is a specialized component designed for use in commercial trucks. Its primary function is to provide precise spacing and adjust clearances within various engine components, ensuring optimal performance and longevity of the truck’s engine system.

Basic Concepts of Shims

Shims are thin, often washer-like spacers used in mechanical systems to fill small gaps, adjust clearances, or provide spacing between components. They play a role in maintaining the correct alignment and operation of machinery by compensating for wear, manufacturing tolerances, or design requirements. Shims can be made from various materials, including metal, plastic, or composite, depending on the application and environmental conditions 1.

Purpose of the 3915128 Shim

This Cummins part is specifically engineered to address clearance issues within truck engines. It is commonly used in the valve train system to ensure proper valve clearance, which is vital for the engine’s efficient operation. By providing the necessary spacing, the shim helps maintain the correct timing and operation of the valves, contributing to the overall performance and reliability of the engine 2.

Key Features

The Cummins 3915128 Shim is characterized by its precise thickness and durable material composition. Typically made from high-quality steel, it offers excellent resistance to wear and corrosion. The shim’s design ensures it can withstand the high temperatures and pressures present in engine environments, providing reliable performance over time.

Benefits of Using the 3915128 Shim

Utilizing this Cummins part offers several advantages. It enhances the precision of valve clearances, which is crucial for the engine’s smooth operation. The shim’s durable construction contributes to the longevity of the engine components it supports. Additionally, by ensuring optimal clearances, the shim can help improve the engine’s efficiency and reduce the risk of mechanical failures 3.

Installation and Usage

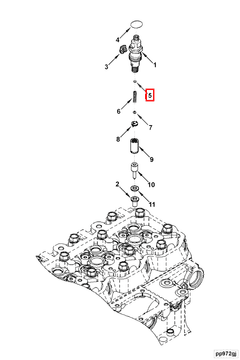

Proper installation of the Cummins 3915128 Shim is critical for its effective function. The process involves carefully measuring the required clearance and selecting the appropriate shim thickness. Tools such as feeler gauges may be used to ensure accuracy. The shim should be placed between the specified components, typically within the valve train, and secured in place according to the manufacturer’s guidelines to ensure correct operation.

Troubleshooting and Maintenance

Common issues with the Cummins 3915128 Shim may include improper clearance, leading to engine performance issues. Regular inspection and maintenance are recommended to ensure the shim remains in good condition. This includes checking for signs of wear or damage and verifying that the clearances are within the manufacturer’s specifications. Prompt replacement of a worn or damaged shim is advised to prevent further engine complications.

Manufacturer Information - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a strong reputation for quality and innovation, Cummins has been a trusted name in the automotive and heavy-duty truck industries for many years. Their commitment to excellence is reflected in the design and performance of components like the 3915128 Shim.

Conclusion

The Cummins 3915128 Shim plays a significant role in maintaining the performance and reliability of commercial truck engines. By ensuring precise clearances within the engine components, this part contributes to the smooth operation and longevity of the engine. Proper installation, regular maintenance, and timely replacement of the shim are essential practices to uphold the engine’s efficiency and prevent mechanical failures.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.