This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

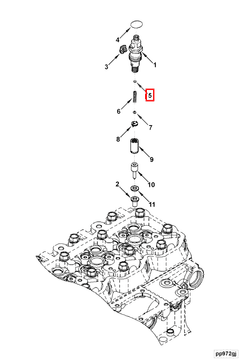

The Cummins 3915138 Shim is a specialized component designed for use in heavy-duty truck operations. Its primary role is to ensure precise alignment and clearance within various mechanical systems, contributing to the overall efficiency and reliability of the truck’s performance.

Basic Concepts of Shims

Shims are thin, often washer-like spacers used in mechanical systems to fill small gaps, ensure proper alignment, and maintain specified clearances between components. They are essential in applications where exact dimensions and tolerances are required to ensure optimal performance and longevity of the machinery 1.

Purpose of the Cummins 3915138 Shim

This Cummins part is specifically designed to play a role in the mechanical systems of heavy-duty trucks. It functions by providing the necessary clearance and alignment for components within the engine or other systems, ensuring that parts operate within their designed parameters. This shim helps in maintaining the integrity of the mechanical assembly, reducing wear and tear, and enhancing the overall performance of the truck 2.

Key Features

The Cummins 3915138 Shim is characterized by its precise material composition, which is chosen for its durability and resistance to wear. The shim’s thickness is carefully calibrated to meet the specific clearance requirements of the applications it is intended for. Its design ensures easy installation and removal, facilitating maintenance and repair processes.

Benefits of Using the 3915138 Shim

Utilizing this shim offers several advantages. It contributes to improved performance by ensuring components are properly aligned and have the correct clearance. This leads to reduced friction and wear, enhancing the durability of the mechanical system. Additionally, the shim aids in maintaining efficiency, as proper alignment and clearance are vital for the optimal operation of heavy-duty trucks 3.

Installation and Usage

Proper installation of the Cummins 3915138 Shim is vital for its effectiveness. It should be installed according to the manufacturer’s guidelines to ensure it meets the required specifications for clearance and alignment. Care should be taken to handle the shim properly to avoid damage, and it should be inspected for any signs of wear or deformation before installation.

Troubleshooting and Maintenance

Regular inspection of the Cummins 3915138 Shim is recommended to identify any signs of wear or failure. Common issues may include improper clearance or alignment, which can lead to increased wear on mechanical components. Maintenance tips include cleaning the shim and its surrounding areas to prevent contamination and ensuring it is correctly installed during any maintenance or repair procedures.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the heavy-duty truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and global presence underscore its leadership in providing reliable and efficient power solutions for various applications.

Conclusion

The Cummins 3915138 Shim plays a significant role in maintaining the efficiency and reliability of heavy-duty truck operations. By ensuring precise alignment and clearance within mechanical systems, this part contributes to the overall performance and longevity of the machinery. Proper installation, regular maintenance, and understanding its benefits are key to maximizing the effectiveness of this Cummins component.

-

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Marine C Command HD Panel System. (n.d.). Owners Manual. Bulletin Number 4332832.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.