This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

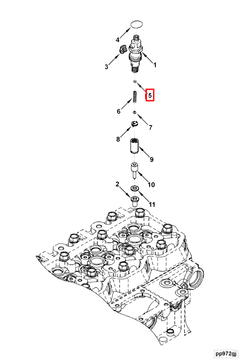

The Cummins 3915140 Shim is a component designed to facilitate precise adjustments in heavy-duty truck systems. Its role is significant in maintaining the optimal performance and longevity of truck engines and other critical systems. Understanding its function and proper application is vital for effective heavy-duty truck maintenance and operation.

Basic Concepts of Shims

Shims are thin, often washer-like spacers used in mechanical systems to fill small gaps, adjust clearances, and ensure proper alignment between components 1. They are crucial in achieving the precise fit and function of various parts within an engine or other machinery. By addressing clearances and alignments, shims help maintain the efficiency and reliability of mechanical systems.

Purpose of the 3915140 Shim

This Cummins part is specifically designed to play a role in the operation of heavy-duty trucks. It is applied in engine components or other critical systems where precise clearances are necessary for optimal performance. This shim aids in the fine-tuning of engine parts, ensuring they operate within the manufacturer’s specified tolerances.

Key Features

The Cummins 3915140 Shim is characterized by several key features that make it suitable for its intended use. It is composed of durable materials that can withstand the harsh conditions within a truck engine. The shim’s thickness is precisely engineered to provide the exact clearance needed for its application. Its design ensures easy installation and removal, facilitating maintenance procedures.

Benefits of Using the 3915140 Shim

Utilizing this shim offers several advantages. It contributes to improved engine performance by ensuring components are properly aligned and clearances are maintained. This can lead to enhanced efficiency and reliability of the engine. Additionally, the shim’s design allows for straightforward installation, reducing downtime during maintenance.

Installation Process

Installing this Cummins part requires careful attention to detail. The process involves selecting the appropriate shim thickness for the application, ensuring the mating surfaces are clean and free of debris, and placing the shim in the designated location. Tools such as torque wrenches may be necessary to secure components in place after the shim has been installed.

Troubleshooting Common Issues

Common issues with the 3915140 Shim may include improper clearances leading to increased wear or noise, or difficulties in installation due to incorrect shim selection. Troubleshooting these problems involves verifying the shim’s thickness and ensuring it is correctly positioned. If issues persist, consulting the manufacturer’s guidelines or seeking professional advice may be necessary.

Maintenance Tips

Regular maintenance of this shim is important for ensuring optimal performance and longevity. This includes periodic inspections to check for wear or damage, and replacing the shim as needed according to the manufacturer’s recommendations. Keeping detailed records of maintenance activities can help identify patterns or issues early, facilitating timely interventions.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a strong reputation in the heavy-duty truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and global presence underscore its leadership in the power industry 2.

Conclusion

The Cummins 3915140 Shim plays a crucial role in the maintenance and operation of heavy-duty trucks by ensuring precise adjustments and optimal performance of engine components. Understanding its function, proper application, and maintenance is essential for professionals in the heavy-duty truck industry to ensure the efficiency, reliability, and longevity of their vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.