3062614

Shutoff Valve Shaft

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3062614 Shutoff Valve Shaft is a component designed for use in heavy-duty truck engines. Its purpose is to regulate the flow of fuel within the engine system, ensuring efficient operation and performance. The significance of this part lies in its ability to maintain precise control over fuel delivery, which is vital for the overall functionality and reliability of the truck’s engine 1.

Basic Concepts of Shutoff Valve Shafts

A shutoff valve shaft is a mechanical component used in engine systems to control the flow of fuel or fluid. It operates by opening and closing a valve that allows or restricts the passage of fuel, thereby regulating the amount that reaches the engine. This control is crucial for maintaining optimal engine performance and efficiency 2.

Purpose of the 3062614 Shutoff Valve Shaft

The 3062614 Shutoff Valve Shaft plays a specific role in the operation of a truck by managing the fuel system. It ensures that the correct amount of fuel is delivered to the engine at the right time, which directly impacts engine performance. By regulating fuel flow, it helps maintain consistent engine operation and contributes to overall efficiency.

Key Features

The 3062614 Shutoff Valve Shaft is characterized by its robust design and the materials used in its construction. It is engineered to withstand the high pressures and temperatures found within a truck’s engine system. Unique characteristics such as precision machining and durable materials enhance its performance and longevity.

Benefits

Using the 3062614 Shutoff Valve Shaft offers several benefits, including improved engine efficiency and reliability. Its precise control over fuel flow can lead to better fuel economy and reduced emissions. Additionally, the durability of the shaft can result in potential cost savings for fleet operators by minimizing the need for frequent replacements.

Installation and Integration

Proper installation of the 3062614 Shutoff Valve Shaft into a truck’s engine system requires attention to detail and adherence to manufacturer guidelines. Prerequisites for successful integration include ensuring compatibility with the engine model and following specific installation procedures to avoid damage or malfunction.

Troubleshooting and Maintenance

Common issues with the 3062614 Shutoff Valve Shaft may include leaks or malfunctions in fuel delivery. Troubleshooting involves checking for proper installation, inspecting for wear or damage, and ensuring all connections are secure. Regular maintenance practices, such as cleaning and lubrication, can help ensure longevity and optimal performance.

Performance Impact

The 3062614 Shutoff Valve Shaft affects the overall performance of the truck by influencing fuel efficiency, emissions, and engine responsiveness. Its role in regulating fuel flow ensures that the engine operates within optimal parameters, contributing to smooth and efficient performance.

Safety Considerations

When working with the 3062614 Shutoff Valve Shaft, it is important to follow safety procedures to prevent accidents or injuries. This includes proper handling during installation and maintenance, adhering to safety guidelines when working with fuel systems, and ensuring all work is performed in a well-ventilated area.

Cummins Overview

Cummins Inc. is a global leader in the design, manufacture, and distribution of engines and related technologies. With a history of innovation and expertise in engine manufacturing, Cummins is committed to producing high-quality automotive components that meet the demanding requirements of heavy-duty applications 3.

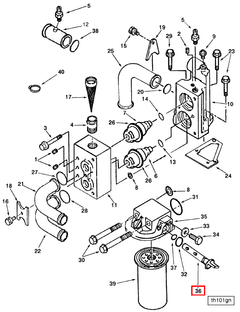

Role of Part 3062614 Shutoff Valve Shaft in Engine Systems

The Shutoff Valve Shaft, identified by part number 3062614, is integral to the operation of several engine components. It facilitates the precise control of fluid flow within the engine system, ensuring optimal performance and efficiency.

Interaction with Corrosion Resistor Head

The Shutoff Valve Shaft works in conjunction with the Corrosion Resistor Head to manage the flow of coolant. This collaboration is essential for maintaining the engine’s temperature within safe operating limits, preventing overheating, and ensuring the longevity of the engine components.

Integration with Housing and Thermostat Housing

Within the Housing and Thermostat Housing, the Shutoff Valve Shaft plays a significant role. It allows for the controlled opening and closing of the thermostat, which regulates the flow of coolant based on the engine’s temperature. This ensures that the engine reaches its optimal operating temperature quickly and maintains it throughout operation.

Coordination with Thermostat

The Shutoff Valve Shaft’s interaction with the Thermostat is pivotal. As the engine warms up, the thermostat begins to open, allowing coolant to flow through the engine. The Shutoff Valve Shaft modulates this flow, ensuring that the engine does not overheat during operation and cools down efficiently when turned off.

Function with Resistor

In systems where a Resistor is used to preheat the engine or maintain temperature, the Shutoff Valve Shaft ensures that the resistor’s influence on the coolant flow is accurately controlled. This precise modulation helps in achieving the desired engine temperature more rapidly and maintains it consistently.

Addressing Corrosion

In environments where Corrosion is a concern, the Shutoff Valve Shaft, when paired with corrosion-resistant materials, helps in mitigating the effects of corrosion on the engine’s cooling system. By controlling the flow of coolant, it ensures that corrosive agents are flushed out regularly, prolonging the life of the engine components.

Conclusion

In summary, the Shutoff Valve Shaft (part 3062614) is a key component in the engine’s cooling system, interacting with various parts to ensure efficient temperature management and protection against corrosion. Its role in modulating coolant flow is essential for the engine’s performance, durability, and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.