3177040

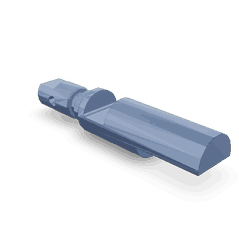

Shutoff Valve Shaft

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction to Shutoff Valve Shafts

Shutoff valve shafts are critical components in commercial truck engines, playing a pivotal role in controlling the flow of fuel and air. Their proper function ensures efficient engine operation and reliable performance. Cummins, a renowned name in the manufacturing of high-quality engine components, has established itself as a leader in producing durable and efficient shutoff valve shafts. Understanding the intricacies of these components is essential for maintaining the performance and longevity of commercial truck engines 1.

Basic Concepts of a Shutoff Valve Shaft

A shutoff valve shaft is a mechanical component designed to regulate the flow of fuel and air within an engine. It consists of several internal components, including the shaft itself, seals, and various connecting parts, all constructed from high-grade materials to ensure durability and precision. The shaft interacts with other engine parts, such as the fuel injector and the engine control unit, to modulate the fuel supply based on engine demands 2.

The Role of the Cummins 3177040 Shutoff Valve Shaft

The Cummins 3177040 shutoff valve shaft is specifically engineered for use in Cummins engines, where it plays a crucial role in enhancing engine efficiency and performance. By precisely controlling the fuel flow, this component ensures that the engine operates smoothly under various conditions. Its reliable function is vital for maintaining engine reliability and extending its operational life 3.

Operational Mechanism of the Cummins 3177040 Shutoff Valve Shaft

The operational process of the Cummins 3177040 shutoff valve shaft involves a series of mechanical actions that regulate fuel flow. When the engine is running, the shaft allows fuel to pass through to the injectors. Upon engine shutdown, the shaft moves to block the fuel flow, ensuring a clean and immediate stop. This mechanism is essential for smooth engine operation and a controlled shutdown process 1.

Troubleshooting and Maintenance of the Cummins 3177040 Shutoff Valve Shaft

Common issues with the shutoff valve shaft include wear, leaks, and failure to operate correctly. Signs of these problems may include difficulty starting the engine, irregular engine performance, or fuel leaks. Diagnostic techniques involve visual inspections, pressure tests, and functional checks to identify any issues. Regular maintenance practices, such as cleaning, lubricating, and inspecting for wear, are recommended to prolong the life of the shutoff valve shaft. Basic maintenance may include disassembling the shaft, checking for wear on the seals and shaft, and replacing any worn components 2.

Cummins: A Leader in Engine Technology

Cummins has a long-standing reputation for excellence in the manufacturing of commercial truck engines. The company’s commitment to quality and innovation is evident in every component it produces, including the 3177040 shutoff valve shaft. Choosing Cummins parts ensures that commercial trucks are equipped with reliable and high-performing engine components 3.

Expert Insights and Best Practices

Experienced engineers and mechanics recommend several best practices for working with shutoff valve shafts. These include careful installation to ensure proper alignment and function, regular maintenance to prevent wear and ensure smooth operation, and prompt attention to any signs of trouble to avoid more significant issues. Real-world examples demonstrate that proper maintenance of the shutoff valve shaft can significantly enhance engine performance and reliability 1.

Shutoff Valve Shaft (Part 3177040) Compatibility with Cummins Engines

The Shutoff Valve Shaft, part number 3177040, is a critical component in various Cummins engine models. This part is essential for the proper functioning of the engine’s shutoff mechanism, ensuring that the engine can be safely and efficiently stopped when required.

Compatible Engine Models

- GTA38 G CMEICS G116C

- K38, K50, KTA38GC CM558

- QSK38 CM2150 MCRS, QSK38 CM850 MCRS

- QSK45 CM500

- QSK50 CM2150 K107, QSK50 CM2150 MCRS, QSK50 CM2350 K108

- QSK60 CM500, QSK60 CM850 MCRS, QSK60 G CM2358 K110, QSK60G

- QSK78 CM500

- QSK95 CM2350 K111, QSK95 CM2350 K113

- QST30 CM2350 T101, QST30 CM552

- QSV91-G4 CM558/CM700 V102, QSV91G

Grouping of Compatible Engines

-

QSK Series Engines:

- QSK38 CM2150 MCRS, QSK38 CM850 MCRS

- QSK45 CM500

- QSK50 CM2150 K107, QSK50 CM2150 MCRS, QSK50 CM2350 K108

- QSK60 CM500, QSK60 CM850 MCRS, QSK60 G CM2358 K110, QSK60G

- QSK78 CM500

- QSK95 CM2350 K111, QSK95 CM2350 K113

-

QST Series Engines:

- QST30 CM2350 T101, QST30 CM552

-

QSV Series Engines:

- QSV91-G4 CM558/CM700 V102, QSV91G

-

Other Compatible Models:

- GTA38 G CMEICS G116C

- K38, K50, KTA38GC CM558

The Shutoff Valve Shaft (part 3177040) is designed to fit seamlessly into these engine models, ensuring compatibility and reliable operation. This part is crucial for maintaining the integrity of the engine’s shutoff system, providing a dependable solution for engine management and safety 3.

Role of Part 3177040 Shutoff Valve Shaft in Engine Systems

The Shutoff Valve Shaft, identified by part number 3177040, is an integral component within various engine systems, facilitating the precise control of fluid flow. This shaft is meticulously engineered to interact with several key components, ensuring optimal engine performance and efficiency.

Interaction with Accessories Mounting and Aftercooler

In systems where accessories mounting is utilized, the Shutoff Valve Shaft plays a significant role in managing the flow of fluids to and from the aftercooler. This ensures that the air entering the engine is adequately cooled, which is essential for maintaining engine efficiency and preventing overheating 1.

Integration with Corrosion Resistor and Related Assemblies

The Shutoff Valve Shaft is also designed to work in conjunction with corrosion resistors, including the corrosion resistor assembly and corrosion resistor head. By controlling the flow of coolant through these components, the shaft helps in maintaining the integrity of the engine’s cooling system, preventing corrosion and ensuring longevity of the engine parts 2.

Coordination with EBM-Corrosion Resistor and EBM-Resistor

In systems equipped with EBM-corrosion resistors and EBM-resistors, the Shutoff Valve Shaft is responsible for regulating the flow of coolant. This regulation is vital for protecting sensitive engine components from the corrosive effects of coolant, thereby enhancing the overall reliability of the engine system 3.

Role in Engine Kit and Filter Systems

Within engine kits, the Shutoff Valve Shaft is often found interacting with filters and the oil pan. Its function here is to control the flow of oil, ensuring that the engine receives the necessary lubrication without excess, which could lead to inefficiencies or damage 1.

Contribution to Auxiliary Cooling and Thermostat Housing

The shaft also contributes to the functionality of auxiliary cooling systems and thermostat housing. By managing the flow of coolant through these components, it aids in maintaining the engine’s operating temperature within optimal ranges, which is crucial for performance and durability 2.

Importance in Product Installation and Package Systems

During product installation and within package systems, the Shutoff Valve Shaft ensures that all components receive the appropriate amount of fluid at the right times. This precise control is essential for the successful integration and operation of new engine systems or upgrades 3.

Conclusion

Understanding and maintaining the Cummins 3177040 shutoff valve shaft is crucial for optimal engine performance. This component plays a vital role in the efficient operation of commercial truck engines, and its proper function is essential for engine reliability and longevity. By following best practices for installation, operation, and maintenance, mechanics and engineers can ensure that their engines perform at their best, providing reliable service for years to come.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.