3818849

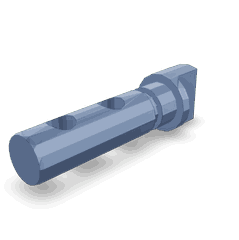

Shutoff Valve Shaft

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Shutoff Valve Shaft 3818849, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the diesel engine manufacturing industry, produces this part to enhance the operational efficiency and reliability of truck engines. The Shutoff Valve Shaft 3818849 is integral to the fluid systems within a truck, ensuring the proper management of fluid flow, which is vital for the engine’s performance 1.

Basic Concepts of Shutoff Valve Shafts

A shutoff valve shaft is a mechanical component used in fluid systems to control the flow of liquids or gases. It operates by opening or closing a valve, thereby regulating the passage of fluid through a system. In the context of a truck’s engine or fuel system, the shutoff valve shaft ensures that fuel or coolant is delivered as needed, maintaining the engine’s operational parameters within safe and efficient limits 2.

Purpose of the Shutoff Valve Shaft 3818849

This Cummins part plays a role in the operation of a truck by controlling the flow of fluids such as fuel or coolant. Its function is to open and close the valve in response to the engine’s requirements, ensuring that the correct amount of fluid is delivered at the right time. This regulation is crucial for maintaining engine performance, preventing overheating, and ensuring efficient fuel consumption 3.

Key Features

The Shutoff Valve Shaft 3818849 is characterized by its robust design and the quality materials used in its construction. It is engineered to withstand the high pressures and temperatures typical of a truck’s engine environment. The shaft’s design includes precision-machined components that ensure smooth operation and durability. Additionally, the use of corrosion-resistant materials enhances its longevity, even in harsh operating conditions 4.

Benefits

The advantages provided by the Shutoff Valve Shaft 3818849 include improved engine efficiency and reliability. Its precise control over fluid flow contributes to optimal engine performance, reducing the risk of overheating and ensuring consistent fuel delivery. Furthermore, the design and materials used in its construction facilitate ease of maintenance, allowing for straightforward inspection and servicing procedures.

Installation and Integration

Installing this part into a truck’s system requires adherence to specific guidelines to ensure proper integration. It is important to follow the manufacturer’s instructions for installation, which may include aligning the shaft with existing components and securing it in place to prevent movement or misalignment. Careful attention to these details ensures the shaft functions correctly within the engine system.

Common Issues and Troubleshooting

Common problems associated with the Shutoff Valve Shaft 3818849 may include leaks, difficulty in operation, or failure to open or close completely. Troubleshooting these issues often involves inspecting the shaft and its connections for signs of wear or damage, ensuring that all components are correctly aligned and secured, and checking for any obstructions that may prevent proper operation.

Maintenance Tips

To ensure the optimal performance and longevity of the Shutoff Valve Shaft 3818849, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, cleaning the shaft and its components to remove any buildup that could impede operation, and lubricating moving parts to ensure smooth operation. Adhering to these maintenance practices helps prevent issues and extends the lifespan of the component.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a pioneer in diesel engine manufacturing, known for its commitment to innovation, quality, and customer satisfaction. The company’s extensive product line and global presence underscore its expertise and dedication to advancing the automotive industry.

Shutoff Valve Shaft Fitment with Cummins Engines

The Shutoff Valve Shaft, part number 3818849, manufactured by Cummins, is a critical component in the operation of several Cummins engine models. This part is integral to the engine’s shutoff mechanism, ensuring that the engine can be safely and effectively stopped when required.

ISM Series Engines

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

- QSM11 CM570

- QSM11 CM876

K Series Engines

- K19

- KTA19GC

L Series Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

M Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

N Series Engines

- N14 MECHANICAL

QSK Series Engines

- QSK19 CM500

- QSK19G

- QSK45 CM500

- QSK60 CM500

- QSK60G

- QSK78 CM500

Role of Part 3818849 Shutoff Valve Shaft in Engine Systems

The 3818849 Shutoff Valve Shaft is an integral component in the orchestration of various engine systems, ensuring optimal performance and efficiency. Its primary function is to regulate the flow of fluids within the engine, interfacing with several key components.

Interaction with Cooling Systems

In cooling systems, the Shutoff Valve Shaft works in conjunction with the water pump and water inlet connection. It controls the flow of coolant to the cooler, maintaining the engine’s temperature within safe operating limits. This regulation is vital for the longevity and performance of the engine, preventing overheating and potential damage.

Integration with Lubrication Systems

Within lubrication systems, the Shutoff Valve Shaft is instrumental in managing the flow of engine oil and lubricating oil. It ensures that oil is distributed evenly throughout the engine, reducing friction and wear on moving parts. This is particularly important in high-stress areas such as the corrosion resistor head and corrosion resistor top level assembly head, where consistent lubrication is essential to prevent corrosion and maintain efficiency.

Role in Water Pump Systems

The Shutoff Valve Shaft is also a key player in water pump systems. It interfaces with the painted water pump and water top level assembly pump, controlling the circulation of coolant. This is crucial for dissipating heat generated by the engine, especially in systems that include a water pump kit or those undergoing a WP conversion.

Contribution to Corrosion Resistance

In systems designed to resist corrosion, such as those incorporating a resistor or corrosion resistor, the Shutoff Valve Shaft ensures that coolant is effectively circulated. This helps in maintaining a consistent temperature and pH level, which are critical factors in corrosion prevention.

Overall System Harmony

Overall, the 3818849 Shutoff Valve Shaft plays a significant role in harmonizing the operation of various engine components. Its ability to regulate fluid flow ensures that each system—whether it’s cooling, lubrication, or corrosion resistance—functions efficiently and effectively, contributing to the overall performance and durability of the engine.

Conclusion

The Shutoff Valve Shaft 3818849 is a critical component in the operation of Cummins engines, ensuring the safe and efficient stopping of the engine when required. Its robust design, precision-machined components, and corrosion-resistant materials contribute to its durability and reliability. Regular maintenance and proper installation are essential to ensure its optimal performance and longevity.

-

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Ling, F. F. (2011). The Automotive Body. Springer Science.

↩ -

Department of Energy. (2015). Department of Energy Fundamentals Handbook. Department of Energy.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.