This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 206497 Sleeve is a specialized component designed for use in heavy-duty truck engines. It plays a significant role in ensuring the smooth operation and longevity of the engine. This part is integral to maintaining the engine’s performance and integrity under demanding conditions.

Basic Concepts of Sleeves

In the context of engine components, a sleeve is a cylindrical component that fits into the engine block 1. Its general function is to provide a smooth surface for the piston to move against, reducing friction and wear. Sleeves are typically made from durable materials to withstand the high pressures and temperatures within the engine. They integrate into the engine assembly by being precisely fitted into the cylinder bores, ensuring a snug and secure fit that contributes to the engine’s overall efficiency and reliability 2.

Purpose of the 206497 Sleeve

This Cummins part plays a specific role in the operation of a truck engine by providing a durable and wear-resistant surface for the piston to travel within the cylinder. This sleeve helps maintain engine integrity by ensuring consistent performance and reducing the likelihood of wear and tear on the cylinder walls. Its design contributes to the engine’s ability to operate efficiently under heavy-duty conditions, thereby supporting overall engine performance and longevity.

Key Features

The 206497 Sleeve boasts several key features that enhance its functionality. It is constructed from high-quality materials, ensuring durability and resistance to wear. The design specifications of this sleeve include precise dimensions to ensure a perfect fit within the engine block. Additionally, it may feature unique attributes such as advanced coatings or treatments that further improve its performance and longevity.

Benefits of Using the 206497 Sleeve

Utilizing this Cummins part offers several advantages. It contributes to improved engine performance by providing a smooth and durable surface for the piston. The sleeve’s durability ensures long-term reliability, reducing the need for frequent replacements. Moreover, its design helps maintain engine efficiency, leading to better overall performance and reduced maintenance costs.

Installation Process

Proper installation of the 206497 Sleeve involves several steps to ensure correct fitting and optimal performance. Begin by preparing the engine block, ensuring the cylinder bore is clean and free of debris. Use the appropriate tools to insert the sleeve into the cylinder, ensuring it is seated correctly. Follow manufacturer guidelines for torque specifications and any additional steps to secure the sleeve in place. Best practices include verifying the sleeve’s alignment and fit to prevent issues during engine operation.

Common Issues and Troubleshooting

Common problems associated with the 206497 Sleeve may include improper fitting, wear, or damage. Potential causes can range from incorrect installation to excessive wear over time. Recommended troubleshooting steps include inspecting the sleeve for signs of damage or misalignment, ensuring it is properly seated, and addressing any issues promptly to prevent further complications. Regular checks and maintenance can help identify and resolve problems early.

Maintenance Tips

To prolong the lifespan of the 206497 Sleeve, regular maintenance practices are crucial. This includes periodic inspections to check for wear or damage. Follow manufacturer-recommended inspection intervals and perform thorough checks during routine engine maintenance. Additionally, ensure the engine is properly lubricated to reduce friction and wear on the sleeve. Adhering to these care instructions will help maintain the sleeve’s performance and extend its service life.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a rich history in producing diesel engines and related components. Established with a commitment to innovation and quality, Cummins has built a reputation for delivering reliable and high-performance engine solutions. The company’s expertise in engine technology and component manufacturing underscores its position as a leader in the industry, providing trusted products for various applications, including heavy-duty trucks.

Role of Part 206497 Sleeve in Engine Systems

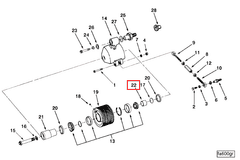

In the orchestration of engine systems, the 206497 Sleeve assumes a significant role, particularly within the fan drive arrangement and the idler pulley mechanism.

Fan Drive Arrangement

Within the fan drive arrangement, the 206497 Sleeve facilitates the smooth operation of the fan by providing a precise fit and reducing friction between moving parts. This ensures that the fan can efficiently dissipate heat from the engine, maintaining optimal operating temperatures. The sleeve’s design allows for consistent rotational movement, which is essential for the fan’s performance in varying engine conditions.

Idler Pulley Mechanism

In the context of the idler pulley, the 206497 Sleeve is instrumental in maintaining the correct tension of the belt that drives auxiliary components such as the alternator, water pump, and air conditioning compressor. By fitting snugly around the idler pulley shaft, the sleeve enables the pulley to adjust the belt tension dynamically as the engine operates. This adjustment is vital for the longevity and efficiency of the belt, as well as the proper functioning of the components it drives.

This part, through its application in these components, contributes to the overall reliability and performance of the engine system. Its role in ensuring smooth operation and proper tensioning cannot be overstated, as it directly influences the efficiency and durability of the engine’s auxiliary systems.

Conclusion

The Cummins 206497 Sleeve is a critical component in heavy-duty truck engines, designed to enhance performance, reliability, and longevity. Its precise fit, durable construction, and role in key engine systems make it an essential part for maintaining optimal engine operation. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.