This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

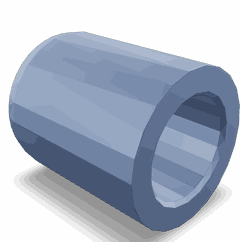

The Cummins 3332237 Sleeve is a component designed for use in commercial trucks, specifically within the engine assembly. This part plays a role in maintaining the operational integrity of the engine by providing a precise fit and reducing friction between moving parts. Its proper function is important for the efficient and reliable performance of the truck’s engine.

Basic Concepts of a Sleeve

In the context of automotive components, a sleeve is a cylindrical component that fits over or into another part to provide support, reduce wear, or facilitate movement. Sleeves are integral to the engine system as they help maintain the alignment and efficiency of various engine components. They are often made from durable materials to withstand high temperatures and pressures within the engine environment 1.

Purpose of the 3332237 Sleeve

The Cummins 3332237 Sleeve is specifically designed to fit within the engine assembly of compatible trucks. Its primary function is to line the cylinder bore, providing a smooth surface for the piston to move against. This reduces friction and wear on the cylinder walls, contributing to the overall efficiency and longevity of the engine.

Key Features

The 3332237 Sleeve is characterized by its robust material composition, typically consisting of high-grade cast iron or other durable alloys. Its design includes precise dimensions to ensure a snug fit within the cylinder bore. Additionally, the sleeve may feature honing or other surface treatments to enhance its performance and durability.

Benefits of Using the 3332237 Sleeve

Incorporating the 3332237 Sleeve into an engine assembly offers several advantages. It contributes to improved engine performance by reducing friction and wear on critical components. The sleeve’s durable construction enhances the engine’s reliability and longevity, making it a valuable component for commercial truck operations.

Installation Process

Installing the Cummins 3332237 Sleeve requires careful attention to detail to ensure a secure and proper fit. The process involves cleaning the cylinder bore to remove any debris or old sleeve material, followed by the insertion of the new sleeve. Specialized tools may be required to press the sleeve into place, ensuring it is seated correctly within the bore. It is important to follow manufacturer guidelines to achieve the best results 2.

Common Issues and Troubleshooting

Common issues associated with the 3332237 Sleeve may include wear and tear over time, or misalignment during installation. Regular inspections can help identify these problems early. Troubleshooting may involve cleaning the cylinder bore, re-honing the surface, or, in severe cases, replacing the sleeve to restore optimal engine performance.

Maintenance Tips

To prolong the lifespan of the Cummins 3332237 Sleeve, regular maintenance practices are recommended. This includes routine inspections for signs of wear or damage, ensuring the cylinder bore remains clean and free of contaminants, and following manufacturer-recommended service intervals. Proper maintenance can significantly extend the operational life of the sleeve and the engine as a whole 3.

Manufacturer Information - Cummins

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance engine components, Cummins has established a strong reputation for excellence. Their products, including the 3332237 Sleeve, are designed with precision and durability in mind, reflecting the company’s dedication to meeting the demanding needs of commercial truck operators.

Compatibility with Cummins Engines

This Cummins part is designed to fit a variety of Cummins engine models, including the QSK45 CM500, QSK60 CM500, QSK60 CM850 MCRS, QSK60G, QSK78 CM500, and QSK95 CM2350 K111. Each of these engines benefits from the precise engineering of the 3332237, which is important for maintaining engine performance, longevity, and reliability.

Role of 3332237 Sleeve in Engine Systems

The 3332237 Sleeve is an essential component in various engine systems, facilitating smooth operation and efficiency. Its applications span across several key components, each playing a distinct role in the overall functionality of the engine.

Alternator Support

In the alternator support system, the 3332237 Sleeve ensures a secure fit and alignment of the alternator. This is vital for the alternator’s ability to generate electrical power efficiently. The sleeve’s precise dimensions and material properties help in reducing friction and wear, thereby enhancing the longevity and performance of the alternator.

Compressor

Within the compressor system, the 3332237 Sleeve is instrumental in maintaining the integrity of the compressor’s moving parts. It provides a smooth surface for the compressor’s shaft, minimizing resistance and ensuring that the compressor operates within its optimal parameters. This results in improved efficiency and reliability of the compressor.

Refrigerant System

In refrigerant systems, the 3332237 Sleeve plays a role in the smooth operation of components such as the expansion valve and compressor. By ensuring a tight and secure fit, the sleeve helps in maintaining the system’s pressure and temperature balance, which is essential for effective cooling and climate control.

Mounting

For mounting purposes, the 3332237 Sleeve is used to secure various engine components in place. Its robust design and material strength provide a stable and durable connection, which is crucial for the overall structural integrity of the engine. This ensures that components remain firmly in place, even under high stress and vibration conditions.

Alternator

In the context of the alternator, the 3332237 Sleeve is used to facilitate the smooth rotation of the alternator’s rotor. This is important for the consistent generation of electrical power. The sleeve’s design helps in reducing mechanical noise and vibration, leading to a more efficient and quieter operation of the alternator.

Conclusion

The Cummins 3332237 Sleeve is a critical component in the maintenance and efficiency of commercial truck engines. Its precise design, durable construction, and compatibility with various Cummins engine models make it an essential part for ensuring optimal engine performance and longevity. Regular maintenance and proper installation are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.