This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

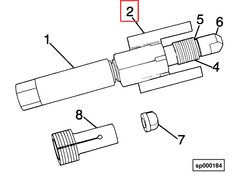

The Body, Injection Sleeve Puller (Part #3377091) by Cummins is a specialized tool designed for the maintenance and repair of diesel engines. Its purpose is to facilitate the removal and installation of injection sleeves, which are components in the fuel injection system of diesel engines. This tool is significant in ensuring that maintenance procedures are performed efficiently and with minimal risk to the engine components.

Purpose and Function

The Body, Injection Sleeve Puller plays a role in the operation and maintenance of diesel engines by aiding in the removal and installation of injection sleeves. Injection sleeves are part of the fuel injection system and their proper function is vital for the engine’s performance. The puller is designed to grip the sleeve securely and extract it without causing damage to surrounding components. Similarly, it assists in the precise installation of new or replacement sleeves, ensuring they are seated correctly within the engine.

Key Features

The Body, Injection Sleeve Puller is characterized by several key features that enhance its functionality. Its design incorporates a robust construction that can withstand the forces involved in extracting and installing injection sleeves. The tool is made from high-quality materials to ensure durability and reliability. Additionally, it features ergonomic handles for comfortable use and precision-machined components to ensure accurate operation.

Benefits

Using the Body, Injection Sleeve Puller offers several advantages in engine maintenance. It improves efficiency by allowing for quicker and easier removal and installation of injection sleeves. The tool reduces the risk of damage to engine components during maintenance procedures. Furthermore, its design promotes ease of use, making it accessible to technicians with varying levels of experience.

Operation

To use the Body, Injection Sleeve Puller effectively, follow these steps: First, ensure the engine is cool and the fuel system is depressurized. Position the puller over the injection sleeve and engage the gripping mechanism. Apply steady, even pressure to extract the sleeve. For installation, align the new sleeve with the puller and use it to seat the sleeve into place. Throughout the process, observe best practices such as maintaining a clean work area and using appropriate personal protective equipment. Safety precautions include ensuring the tool is securely engaged before applying force and avoiding over-tightening to prevent damage.

Troubleshooting and Maintenance

Common issues with the Body, Injection Sleeve Puller may include difficulty in gripping the sleeve or resistance during extraction. These can often be resolved by ensuring the tool is correctly positioned and that all components are clean and free from debris. Regular maintenance of the puller involves cleaning it after each use, inspecting for wear or damage, and lubricating moving parts as necessary to ensure its longevity and effectiveness.

Cummins Corporation Overview

Cummins Corporation, a leader in the diesel engine industry, has a history of innovation and commitment to quality. Founded in 1919, Cummins has grown to become a global power leader, providing diesel and natural gas engines, as well as related technologies. The company is known for its focus on sustainability, efficiency, and reliability in its products, including a wide range of tools and components for engine maintenance and repair.

Applications

The Body, Injection Sleeve Puller is commonly used in the maintenance and repair of various types of diesel engines, including those found in heavy-duty trucks, agricultural equipment, and industrial machinery. Its application is widespread across industries that rely on diesel engines for their operations, making it a versatile tool in the technician’s arsenal.

Safety Considerations

When using the Body, Injection Sleeve Puller, it is important to observe several safety guidelines. Ensure the engine is cool and the fuel system is depressurized before beginning work. Use the tool in a well-ventilated area to avoid inhalation of fuel vapors. Wear appropriate personal protective equipment, including gloves and safety glasses, to protect against injury. Follow the manufacturer’s instructions for use and maintenance of the tool to prevent accidents and ensure safe operation.

Role of Part 3377091 Body, Inj Sleeve Puller in Engine Systems

The Part 3377091 Body, Inj Sleeve Puller is a tool designed for the precise removal of injector sleeves from engine blocks. This component is specifically engineered to interface with the Injector Sleeve Remover system, ensuring a secure and efficient extraction process.

When integrated with the Injector Sleeve Remover, the Part 3377091 Body provides a stable platform that allows for the application of necessary force to dislodge the injector sleeve without causing damage to surrounding engine components. The design of this puller body ensures that the force is evenly distributed, minimizing the risk of misalignment or component failure during the removal process.

In practical application, the Part 3377091 Body is attached to the injector sleeve, and the Injector Sleeve Remover is then used to apply pulling force. This systematic approach facilitates the safe and effective extraction of injector sleeves, which is a common maintenance or repair task in engine servicing. The tool’s design enhances the mechanic’s ability to perform this task with greater accuracy and reduced physical strain, ultimately contributing to more efficient and reliable engine maintenance procedures.

Conclusion

The Body, Injection Sleeve Puller (Part #3377091) by Cummins is a valuable tool for technicians working on diesel engines. Its robust design, ease of use, and the benefits it offers in terms of efficiency and safety make it an essential component in the toolkit for engine maintenance and repair. By understanding its purpose, features, and proper operation, technicians can ensure that engine maintenance procedures are performed effectively and with minimal risk to the engine components.

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022. Reif, Konrad. Automotive Mechatronics. Springer Vieweg, 2015. Majewski, Addy, and Hannu Jaskelainen. Diesel Emissions and Their Control: Second Edition. SAE International, 2023. Zhan, Quansheng, Eben, Shengbo, and Deng, Li Kun. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018. Cummins Corporation. Fault Code Troubleshooting Manual. Bulletin Number 4383852, KTA19 G CMEICS K123.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.