This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3643932 Sleeve is a component designed for use in heavy-duty truck engines. It serves a specific function within the engine’s structure, contributing to the overall performance and durability of the engine. Understanding its purpose and role is fundamental for maintaining and optimizing engine efficiency.

Basic Concepts of a Sleeve

A sleeve, in the context of an engine, is a cylindrical component that fits into the engine block. Its general function is to provide a smooth surface for the piston to move against, reducing friction and wear 1. In internal combustion engines, sleeves play a role in enhancing the engine’s longevity by allowing for the replacement of worn-out parts without the need to replace the entire engine block.

Purpose of the 3643932 Sleeve

The 3643932 Sleeve is specifically engineered to fit into the Cummins engine block, where it serves as a liner for the cylinder. This Cummins part plays a role in maintaining engine performance by ensuring a precise fit and smooth operation of the piston. It contributes to the engine’s durability by withstanding high pressures and temperatures, which are common in heavy-duty applications.

Key Features

The 3643932 Sleeve is characterized by its material composition, typically made from a durable alloy that can withstand the harsh conditions within an engine. Its design includes precise dimensions to ensure a snug fit within the engine block, which is crucial for optimal engine performance. Unique attributes of this sleeve may include coatings or treatments that further enhance its resistance to wear and corrosion.

Benefits of Using the 3643932 Sleeve

Incorporating the 3643932 Sleeve into a truck engine can lead to improved engine efficiency, as it reduces friction between moving parts. This component contributes to the engine’s longevity by providing a replaceable part that can be serviced without requiring a complete engine overhaul. Additionally, the sleeve enhances the reliability of the engine, ensuring consistent performance under demanding conditions.

Installation Process

Installing the 3643932 Sleeve requires careful attention to detail to ensure a secure fit. The process involves cleaning the engine block to remove any debris, followed by the insertion of the sleeve. Specialized tools may be required to press the sleeve into place, ensuring it is seated correctly. Best practices include verifying the sleeve’s alignment and fit to prevent issues during engine operation.

Common Issues and Troubleshooting

Common problems associated with the 3643932 Sleeve may include wear and tear over time or issues arising from improper installation. Troubleshooting methods involve inspecting the sleeve for signs of damage or misalignment. Addressing these issues promptly can prevent further engine damage and ensure the component continues to perform its intended function.

Maintenance Tips

Regular maintenance of the 3643932 Sleeve is key to ensuring its longevity and optimal performance. This includes periodic inspections for wear or damage, as well as cleaning the sleeve to remove any buildup that could affect its operation. Adhering to recommended inspection intervals and following proper cleaning procedures will help maintain the sleeve’s condition and contribute to the overall efficiency of the engine.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, particularly known for its heavy-duty truck components. With a rich history of innovation and quality, Cummins has built a reputation for producing reliable and high-performance engine parts. The company’s commitment to excellence is evident in its wide range of products, designed to meet the demanding requirements of heavy-duty applications.

Compatibility of 3643932 with Cummins Engines

The 3643932, manufactured by Cummins, is designed to fit within several of their engine models. This part is integral to the engine’s operation, providing a crucial interface between the piston and the cylinder wall. Here is a detailed look at its compatibility with the specified engines:

QSK45 CM500 and QSK60 CM500

The 3643932 is compatible with both the QSK45 CM500 and QSK60 CM500 engines. These engines are part of Cummins’ QSK series, known for their robust performance and reliability in various industrial applications. The sleeve ensures a smooth and efficient operation by maintaining the correct clearance between the piston and the cylinder wall, which is essential for optimal engine performance and longevity.

QSK60 CM850 MCRS

The 3643932 also fits the QSK60 CM850 MCRS engine. This engine is an advanced model within the QSK series, offering enhanced power and efficiency. The sleeve’s precise fit is critical in this engine, as it must withstand higher pressures and temperatures, ensuring that the engine operates smoothly and efficiently under demanding conditions.

QSK78 CM500

Lastly, the 3643932 is also compatible with the QSK78 CM500 engine. This engine is another member of the QSK series, designed for heavy-duty applications. The sleeve’s role in this engine is to provide a reliable barrier between the piston and the cylinder wall, ensuring that the engine can handle the rigors of continuous operation without wear and tear.

In summary, the 3643932 is a versatile component that fits seamlessly into the QSK45 CM500, QSK60 CM500, QSK60 CM850 MCRS, and QSK78 CM500 engines, ensuring optimal performance and durability across these models.

Role of 3643932 in Engine Systems

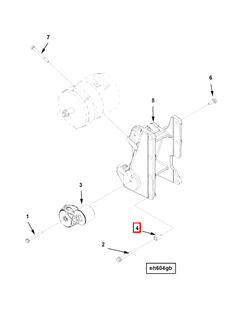

The 3643932 is integral to the efficient operation of various engine components. In the context of the mounting system, this Cummins part facilitates the secure attachment of the engine to the vehicle’s chassis. It ensures that vibrations are effectively managed, contributing to the overall stability and longevity of the engine mounting setup.

When considering the alternator, the 3643932 plays a significant role in maintaining the precise alignment of the alternator’s pulley. This alignment is essential for the efficient transfer of power from the engine to the alternator, ensuring consistent electrical output and reliable performance of the vehicle’s electrical systems 2.

Additionally, the sleeve aids in reducing wear and tear on the alternator’s components by providing a smooth surface for rotation, which is vital for the sustained operation of the charging system.

Conclusion

The Cummins 3643932 Sleeve is a critical component in heavy-duty truck engines, offering benefits such as reduced friction, enhanced engine longevity, and improved reliability. Its precise design and material composition ensure it can withstand the demanding conditions of heavy-duty applications. Regular maintenance and proper installation are key to maximizing the performance and lifespan of this part. Understanding the role and benefits of the 3643932 Sleeve is essential for anyone involved in the maintenance and optimization of Cummins engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.