3824500

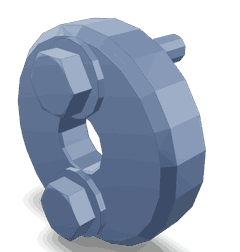

Crankshaft Wear Sleeve Installer

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Crankshaft Wear Sleeve Installer (Part #3824500) by Cummins is a specialized tool designed for the precise installation of wear sleeves on crankshafts. This Cummins part is significant in the maintenance and repair of heavy-duty truck engines, as it ensures the accurate placement of wear sleeves, which are essential for repairing worn or damaged crankshaft journals.

Purpose and Function

This part plays a role in the repair and maintenance of crankshafts by facilitating the installation of wear sleeves. These sleeves are used to restore the dimensions and surface integrity of crankshaft journals that have been worn down due to use or damage. The installer ensures that the sleeves are seated correctly and uniformly, which is important for the crankshaft’s balanced operation and the overall performance of the engine 1.

Key Features

The Crankshaft Wear Sleeve Installer is designed with precision and durability in mind. It features a robust construction that can withstand the rigors of heavy-duty engine repair. The tool incorporates unique attributes such as adjustable components to accommodate various crankshaft sizes and journals, ensuring a snug fit for each installation. Additionally, the installer is equipped with alignment guides to enhance accuracy during the installation process 2.

Benefits of Using a Crankshaft Wear Sleeve Installer

Using a Crankshaft Wear Sleeve Installer offers several advantages. It provides improved precision in the installation of wear sleeves, which is important for the crankshaft’s smooth operation. The tool also reduces repair time by streamlining the installation process. Furthermore, the accurate placement of wear sleeves contributes to enhanced engine performance and longevity, as it ensures that the crankshaft operates within its specified tolerances 3.

Installation Process

To use the Crankshaft Wear Sleeve Installer, begin by preparing the crankshaft by cleaning the journal surfaces and ensuring they are free of debris. Next, align the installer with the crankshaft journal and position the wear sleeve according to the manufacturer’s instructions. Use the tool to press the sleeve into place, ensuring even distribution of force. Throughout the process, observe safety precautions such as wearing protective gear and ensuring the engine is securely supported.

Troubleshooting and Maintenance

Common issues with the Crankshaft Wear Sleeve Installer may include misalignment or difficulty in seating the wear sleeve. To address these, verify that the installer is correctly aligned with the crankshaft journal and that all components are securely fastened. Regular maintenance of the tool, such as cleaning and inspecting for wear, will help ensure its longevity and effectiveness.

Role in Engine Repair and Maintenance

Crankshaft maintenance is a key aspect of engine repair and maintenance, as the crankshaft’s condition directly affects engine performance and reliability. The Crankshaft Wear Sleeve Installer is an integral tool in this process, providing a means to repair and restore crankshafts to their original specifications, thereby contributing to the overall health and performance of the engine.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the heavy-duty truck industry. The company’s product range includes engines, components, and technologies that power commercial vehicles, construction equipment, agricultural machinery, and more. Cummins’ dedication to excellence is evident in its continuous pursuit of advancements in engine technology and components, ensuring that its products meet the demanding requirements of modern heavy-duty applications.

Conclusion

The Crankshaft Wear Sleeve Installer (Part #3824500) by Cummins is a critical tool in the maintenance and repair of heavy-duty truck engines. Its precise design and robust construction ensure accurate and efficient installation of wear sleeves, contributing to the overall performance and longevity of the engine. Regular maintenance and proper use of this Cummins part are essential for optimal engine health and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.