This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 181040 Solenoid is a component designed for use in commercial truck operations. It serves a specific function within the truck’s systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is key to maintaining and optimizing truck performance.

Basic Concepts of Solenoids

A solenoid is an electromechanical device that converts electrical energy into mechanical motion. It consists of a coil of wire wrapped around a metal core. When an electric current passes through the coil, it generates a magnetic field that moves the core, producing linear motion. Solenoids are widely used in automotive systems for various applications, including controlling valves, switches, and other mechanical components 1.

Purpose of the 181040 Solenoid in Truck Operations

This Cummins part plays a role in the operation of commercial trucks by controlling specific functions within the truck’s systems. It is integrated into the truck’s electrical and mechanical systems to manage the flow of fluids or the operation of certain components. This solenoid is typically used in fuel systems, where it helps regulate the flow of fuel or other substances, ensuring the engine operates efficiently under various conditions 2.

Key Features

The 181040 Solenoid is characterized by its robust design and construction. It is built using high-quality materials to ensure durability and reliability in demanding commercial truck environments. The solenoid’s design includes precise engineering to ensure accurate and consistent performance. Additionally, it may feature protective coatings or seals to enhance its resistance to environmental factors such as moisture, dust, and extreme temperatures.

Benefits of Using the 181040 Solenoid

Incorporating this part into truck systems offers several advantages. It contributes to improved efficiency by ensuring precise control over the functions it manages. The solenoid’s reliable operation helps maintain consistent performance, reducing the likelihood of system failures. Furthermore, its design enhances the overall reliability of the truck’s systems, leading to potentially lower maintenance costs and increased uptime 3.

Installation and Integration

Installing the 181040 Solenoid requires careful attention to ensure proper integration into the truck’s systems. It is important to follow manufacturer guidelines for installation, which may include specific wiring connections and mounting procedures. Ensuring the solenoid is correctly installed and integrated is crucial for its effective operation and the overall performance of the truck’s systems.

Troubleshooting and Maintenance

Regular maintenance and timely troubleshooting are important for the longevity and optimal performance of the 181040 Solenoid. Common issues may include electrical faults, mechanical wear, or environmental damage. Troubleshooting procedures may involve checking electrical connections, testing the solenoid’s operation, and inspecting for physical damage. Maintenance tips include keeping the solenoid clean, ensuring proper electrical connections, and monitoring its operation for any signs of wear or malfunction.

Performance in Various Conditions

The 181040 Solenoid is designed to perform reliably under a range of operating conditions. It is built to withstand varying temperatures, loads, and environments commonly encountered in commercial truck operations. However, extreme conditions may require additional considerations or adaptations to ensure optimal performance. Regular monitoring and maintenance can help address any performance issues that arise under different operating conditions.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company offers a wide range of products and services designed to meet the diverse needs of its customers, contributing to the efficiency and performance of commercial vehicles worldwide.

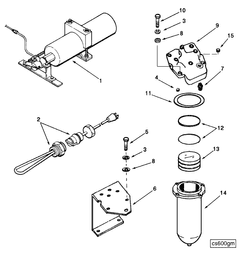

Role of 181040 Solenoid in Lubricating Oil Primer Systems

In lubricating oil primer systems, the 181040 Solenoid is integral to the efficient operation and maintenance of engine lubrication. This solenoid is responsible for controlling the flow of oil to various engine components, ensuring that they receive the necessary lubrication at the appropriate times.

When the engine is started, the solenoid activates, allowing oil to flow from the oil reservoir through the oil filter and into the engine’s lubrication circuits. This process primes the system, ensuring that critical components such as the crankshaft, camshaft, and pistons are adequately lubricated from the moment the engine begins to operate.

The solenoid also plays a role in maintaining oil pressure within the system. By regulating the flow of oil, it helps to stabilize pressure levels, which is essential for the consistent performance of the lubrication system. This regulation is particularly important during engine start-up, when oil pressure needs to be quickly established to protect engine components from wear.

Additionally, the solenoid interacts with the oil pressure sensor and the engine control unit (ECU). The ECU monitors oil pressure and, based on sensor readings, can signal the solenoid to adjust oil flow as needed. This feedback loop ensures that the lubrication system adapts to changing engine conditions, such as variations in temperature or load, thereby optimizing engine performance and longevity.

Conclusion

The Cummins 181040 Solenoid is a vital component in commercial truck operations, contributing to the efficiency and reliability of the vehicle. Its role in controlling fluid flow and managing system functions is crucial for maintaining optimal engine performance. Regular maintenance and proper installation are essential for ensuring the longevity and effectiveness of this part in demanding truck environments.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.