This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 128942 Mounting Spacer is a component designed for use in heavy-duty truck operations. Its primary role is to ensure proper alignment and spacing between various truck components during assembly and operation. This part is integral to maintaining the structural integrity and efficient functioning of the truck’s engine and related systems.

Purpose and Function

The mounting spacer plays a significant role in the assembly and operation of truck components by providing the necessary distance and alignment between parts. It ensures that components are correctly positioned relative to each other, which is vital for the smooth operation of the truck. Proper alignment facilitated by the spacer helps in reducing undue stress on the components, thereby enhancing the overall performance and longevity of the truck 1.

Key Features

The Cummins 128942 Mounting Spacer is characterized by its robust design and high-quality materials. It is crafted to withstand the demanding conditions typical of heavy-duty truck environments. The spacer’s design includes precise dimensions to ensure accurate fitting, and it is made from durable materials that resist wear and corrosion. These attributes contribute to its reliable performance and durability in challenging operational scenarios 2.

Benefits

Utilizing the Cummins 128942 Mounting Spacer offers several advantages. It enhances component alignment, which is crucial for the efficient operation of the truck. Improved alignment leads to reduced wear on interconnected parts, thereby extending their service life. Additionally, the spacer contributes to the overall performance of the truck by ensuring that all components function within their designed parameters 3.

Installation Process

Installing the Cummins 128942 Mounting Spacer requires adherence to specific procedures to ensure optimal performance. The process involves carefully positioning the spacer between the designated components, ensuring it is correctly aligned. It is important to follow the manufacturer’s guidelines for torque specifications and any additional installation instructions to maintain the integrity of the spacer and the components it supports.

Troubleshooting and Maintenance

Common issues with mounting spacers may include misalignment or wear over time. Troubleshooting these issues involves checking the spacer for proper fit and condition, and ensuring that it is correctly installed. Regular maintenance, such as inspecting the spacer for signs of wear or damage, can help prolong its lifespan and ensure continued efficient operation of the truck.

Compatibility and Usage

The Cummins 128942 Mounting Spacer is designed for use in specific types of trucks and engine models. Its application varies depending on the truck’s configuration and the engine model. It is important to verify compatibility to ensure the spacer is suitable for the intended application, contributing to the efficient and reliable operation of the truck.

Manufacturer Overview - Cummins

Cummins Inc. is a well-established manufacturer in the automotive and heavy-duty truck industry. With a rich history of innovation and quality, Cummins offers a wide range of products designed to meet the demanding requirements of heavy-duty applications. The company’s reputation for reliability and performance is built on a commitment to excellence in design, manufacturing, and customer service.

Cummins Mounting Spacer 128942 in V28 Engines

The Cummins Mounting Spacer, part number 128942, is a critical component in the V28 engine series. This part is integral to the engine’s assembly, ensuring proper alignment and stability of various engine components. Its design and precision are essential for maintaining the structural integrity and operational efficiency of the engine.

In the V28 engine, the mounting spacer plays a pivotal role in securing the engine to the chassis or engine block. It ensures that the engine is positioned correctly, reducing the risk of misalignment that could lead to mechanical failures or performance issues. The spacer’s material and construction are specifically tailored to withstand the high stresses and vibrations typical in heavy-duty engines like the V28.

The use of Cummins Mounting Spacer 128942 across different variants of the V28 engine underscores its versatility and importance. Whether in industrial, marine, or military applications, this spacer is a testament to Cummins’ commitment to quality and reliability. Its consistent performance in various demanding environments highlights its robustness and suitability for critical engine mounting tasks.

Component Usage

The Cummins 128942 Mounting Spacer is an essential component that facilitates the proper alignment and spacing between various engine components, ensuring optimal performance and durability.

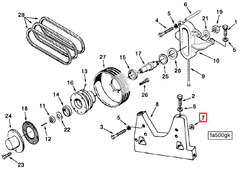

When integrated with the Fan Bracket, the Mounting Spacer allows for precise positioning of the fan assembly. This ensures that the fan operates at the correct distance from the engine, promoting efficient cooling and reducing the risk of contact with other components. The spacer helps maintain consistent airflow, which is vital for the engine’s thermal management.

In conjunction with the Fan Drive Arrangement, the Mounting Spacer plays a significant role in maintaining the structural integrity of the fan system. It ensures that the drive components are correctly spaced, which is important for the smooth operation of the fan. This spacing is essential for minimizing vibrations and wear on the drive belts or chains, thereby enhancing the longevity of the fan drive system.

Overall, the Cummins 128942 Mounting Spacer is a key element in the assembly and function of these engine components, contributing to the reliable and efficient operation of the engine system.

Conclusion

The Cummins 128942 Mounting Spacer is a vital component in heavy-duty truck operations, ensuring proper alignment and spacing between engine components. Its robust design, high-quality materials, and precise dimensions contribute to the efficient and reliable operation of the truck. Regular maintenance and proper installation are essential to maximize the benefits of this part, ensuring the longevity and performance of the truck’s engine and related systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.