This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

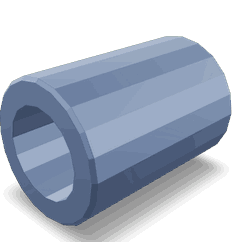

The Cummins 3590445 Mounting Spacer is a component designed for use in heavy-duty truck applications. Its primary role is to facilitate proper alignment and spacing between various truck components during assembly and operation. This ensures that the components function efficiently and maintain their integrity over time 1.

Purpose and Function

The mounting spacer plays a significant role in the assembly and operation of truck components by providing the necessary distance and alignment between parts. It helps in maintaining the correct spacing, which is vital for the proper functioning of the assembly. This spacing ensures that components do not interfere with each other, reducing the risk of misalignment and subsequent mechanical issues 2.

Key Features

The Cummins 3590445 Mounting Spacer is characterized by its robust design and high-quality materials. It is engineered to withstand the rigors of heavy-duty truck environments. The spacer is made from durable materials that offer resistance to wear and corrosion, ensuring long-lasting performance. Its design includes precise dimensions to guarantee accurate spacing and alignment, contributing to the overall reliability of the truck’s components 3.

Benefits

Using the Cummins 3590445 Mounting Spacer offers several advantages. It enhances component alignment, which is crucial for the efficient operation of the truck’s systems. By maintaining proper spacing, it reduces wear and tear on adjacent parts, leading to longer component life. Additionally, the spacer contributes to improved overall system efficiency by ensuring that all components operate within their designed parameters 4.

Installation Guidelines

Proper installation of the Cummins 3590445 Mounting Spacer is vital for optimal performance. Begin by ensuring that the mating surfaces are clean and free from debris. Position the spacer between the components as per the manufacturer’s instructions. Secure the components in place, ensuring that the spacer is correctly aligned and does not shift during the process. Following these best practices will help ensure the spacer functions effectively and contributes to the longevity of the truck’s components 5.

Troubleshooting and Maintenance

Common issues with mounting spacers may include misalignment or damage due to wear. If such issues arise, it is important to inspect the spacer for any signs of wear or damage. Ensure that it is correctly positioned and that there are no obstructions affecting its function. Regular maintenance involves checking the spacer during routine inspections and replacing it if any signs of wear are detected. This proactive approach helps in prolonging the lifespan of the spacer and ensuring continued reliable operation 6.

Compatibility and Applications

The Cummins 3590445 Mounting Spacer is designed for use in specific truck models and engine configurations. It is commonly applied in various heavy-duty truck scenarios where precise component alignment and spacing are required. Its compatibility ensures that it integrates seamlessly into the truck’s systems, contributing to efficient and reliable performance 7.

Manufacturer Information

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its commitment to quality and innovation. With a rich history of producing reliable truck components, Cummins has established a strong reputation for delivering high-performance parts. The company’s dedication to excellence is reflected in the design and manufacturing of the Cummins 3590445 Mounting Spacer, ensuring it meets the demanding requirements of heavy-duty truck applications 8.

Cummins Engine Part 3590445: Mounting Spacer Compatibility

The Cummins part 3590445, a Mounting Spacer, is designed to fit a variety of Cummins engines. This part is integral in ensuring proper alignment and stability of engine components. Below is a detailed breakdown of the engines with which this mounting spacer is compatible.

QSK19 Series

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM2350 K144G

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK19G

- QSK19 CM2350 K111

The QSK19 series engines are known for their robust performance and reliability. The part 3590445 is specifically engineered to fit these models, ensuring that the engine mounts are correctly spaced and aligned.

QSK38 Series

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

The QSK38 series engines are designed for heavy-duty applications. The mounting spacer part 3590445 is compatible with these engines, providing the necessary support and stability for their demanding operations.

QSK45 and QSK50 Series

- QSK45 CM500

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

These engines are engineered for high-performance applications. The part 3590445 ensures that the engine mounts are properly spaced, contributing to the overall efficiency and longevity of these engines.

QSK60 Series

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK60G

The QSK60 series engines are designed for a variety of applications, from industrial to marine. The mounting spacer part 3590445 is compatible with these engines, ensuring precise alignment and stability.

QSK78 Series

- QSK78 CM500

The QSK78 series engines are known for their durability and efficiency. The part 3590445 is designed to fit these engines, providing the necessary support for their specific mounting requirements.

QST30 Series

- QST30 CM2350 T101

- QST30 CM552

The QST30 series engines are engineered for high-performance applications. The mounting spacer part 3590445 is compatible with these engines, ensuring that the engine mounts are correctly aligned.

QSV91 Series

- QSV91-G4 CM558/CM700 V102

- QSV91G

The QSV91 series engines are designed for a variety of applications. The part 3590445 is compatible with these engines, ensuring proper alignment and stability.

QSW/QSV82 and QSW36

- QSW/QSV82

- QSW36

These engines are known for their reliability and performance. The mounting spacer part 3590445 is designed to fit these engines, ensuring that the engine mounts are correctly spaced and aligned.

The Cummins part 3590445, a Mounting Spacer, is a critical component for ensuring the proper alignment and stability of the aforementioned engines. Its compatibility across various Cummins engine models underscores its versatility and importance in maintaining engine performance and longevity 9.

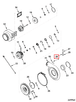

Role of Part 3590445 Mounting Spacer in Engine Systems

The Part 3590445 Mounting Spacer is instrumental in ensuring the proper alignment and secure fitting of various components within engine systems. When integrating an Aftermarket Turbocharger or an Assembly Turbocharger, this spacer facilitates the correct positioning of the turbocharger relative to the engine block, allowing for optimal performance and reduced stress on the mounting points.

In systems equipped with a Camshaft and Gear setup, the mounting spacer ensures that the camshaft is accurately aligned with the crankshaft and other related components. This alignment is essential for the precise timing required for efficient engine operation.

For the Fuel Control Module and Gear Fuel Pump Kit, the spacer plays a role in maintaining the structural integrity of the fuel delivery system. It ensures that the fuel pump and control module are securely mounted, which is vital for consistent fuel pressure and delivery.

When dealing with Injectors and the Integrated Fuel System Module Service/Repair Kit, the mounting spacer helps in achieving the correct spacing between the injectors and the fuel rail. This ensures that fuel is distributed evenly across all cylinders, contributing to balanced engine performance.

In high-performance applications involving Performance Parts and Turbocharger Aftermarket components, the spacer is often used to accommodate additional clearance required by upgraded parts. This is particularly important in Turbocharger Assembly and Turbocharger Kit installations, where precise fitting is necessary to handle increased boost pressures and thermal expansion.

Lastly, in conjunction with a V Band Clamp, the mounting spacer ensures that exhaust and intake components are securely fastened without compromising the integrity of the connections. This is essential for maintaining a sealed system, which is critical for turbocharger efficiency and overall engine performance 10.

Conclusion

The Cummins 3590445 Mounting Spacer is a vital component in heavy-duty truck and engine systems, ensuring proper alignment, spacing, and stability of various components. Its robust design, high-quality materials, and precise dimensions contribute to the overall efficiency and reliability of the systems it supports. Proper installation, regular maintenance, and understanding its role in different engine configurations are key to maximizing its benefits and ensuring the longevity of the components it supports.

-

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Reif, K. (Ed.). (2014). Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 6314881.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 6314881.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 6314881.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 6314881.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 6314881.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 6314881.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 6314881.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.