This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3631396 Mounting Spacer is a component designed for use in heavy-duty truck applications. Its primary role is to ensure proper alignment and spacing between various truck components, contributing to the overall efficiency and reliability of the vehicle.

Purpose and Function

The mounting spacer serves a function in truck assemblies by facilitating the correct alignment and spacing between components. This ensures that parts fit together precisely, which is important for the smooth operation of the truck. Proper alignment reduces the risk of component wear and tear, enhances performance, and contributes to the longevity of the truck’s systems 1.

Key Features

This Cummins part is engineered with specific features to enhance its performance and durability. It is typically made from high-quality materials that can withstand the rigors of heavy-duty use. The spacer’s dimensions are precisely engineered to fit specific applications, ensuring a snug and secure fit. Its design characteristics are tailored to provide optimal performance under demanding conditions 2.

Benefits

Using the Cummins 3631396 Mounting Spacer offers several advantages. It improves component alignment, which can lead to reduced vibration during operation. This, in turn, contributes to a smoother ride and less stress on the truck’s components. The spacer’s durable construction enhances the overall durability of the truck’s systems, and its proper function contributes to the efficiency of the vehicle 3.

Installation and Usage

Proper installation of the Cummins 3631396 Mounting Spacer is key to ensuring optimal performance. The installation process involves carefully positioning the spacer between the components it is designed to separate. It is important to follow the manufacturer’s guidelines for torque specifications to ensure that the spacer is securely in place without being overtightened, which could lead to damage 4.

Troubleshooting and Maintenance

Common issues with mounting spacers may include improper alignment or wear over time. Regular inspection and maintenance can help identify these issues early. If a spacer is found to be misaligned or damaged, it should be replaced to prevent further complications. Keeping the spacer clean and free from debris will also help maintain its performance and longevity.

Compatibility and Applications

The Cummins 3631396 Mounting Spacer is designed for use in specific heavy-duty truck models and systems. It is important to verify compatibility with the truck’s make and model to ensure proper fit and function. The spacer is used in various truck systems and components, playing a role in maintaining the integrity and performance of these systems.

Manufacturer Information

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its commitment to producing high-quality components for commercial vehicles. With a history of innovation and a strong reputation for reliability, Cummins components are trusted by professionals in the industry for their performance and durability.

Cummins Engine Part 3631396: Mounting Spacer Compatibility

The Cummins part number 3631396, a Mounting Spacer, is designed to fit a variety of Cummins engines. This part is crucial for ensuring proper alignment and stability of engine components. Below is a detailed description of its compatibility with the specified engines:

K38 and K50 Engines

The Mounting Spacer 3631396 is compatible with the K38 and K50 engines. These engines are known for their robust design and reliability, often used in heavy-duty applications. The spacer ensures that the engine mounts are correctly positioned, which is vital for maintaining engine integrity and performance.

QSK38 CM2150 MCRS and QSK38 CM850 MCRS Engines

The QSK38 CM2150 MCRS and QSK38 CM850 MCRS engines also utilize the Mounting Spacer 3631396. These engines are part of the QSK series, which is renowned for its high power output and efficiency. The spacer plays a role in the mounting system, ensuring that the engine is securely fastened to the chassis, thereby reducing vibrations and enhancing operational longevity.

QSK60 CM500 and QSK78 CM500 Engines

The QSK60 CM500 and QSK78 CM500 engines are another set of engines that are compatible with the Mounting Spacer 3631396. These engines are designed for demanding applications, providing substantial power and durability. The spacer is essential in maintaining the precise alignment of the engine, which is crucial for optimal performance and to prevent potential mechanical failures.

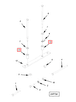

Role of Part 3631396 Mounting Spacer in Engine Systems

The Part 3631396 Mounting Spacer is a component in the assembly and arrangement of various engine systems. It facilitates the proper alignment and spacing between components, ensuring optimal performance and longevity of the engine.

Integration with Engine Components

-

Accessories and Electrical Arrangement: The Mounting Spacer is used to maintain the correct distance between accessories and electrical components. This ensures that there is no interference between moving parts and that electrical connections remain secure and unaffected by vibrations.

-

Oil Fill and Arrangement: In the oil fill system, the Mounting Spacer helps in aligning the oil fill cap and associated plumbing. This is vital for maintaining the integrity of the oil fill process and preventing leaks.

-

Turbocharger and Breather Systems: When integrating the turbocharger and breather systems, the Mounting Spacer ensures that these components are positioned correctly. This is important for the efficient operation of the turbocharger and the proper functioning of the breather system, which helps manage crankcase pressure.

-

Crankcase and Kit Assembly: The Mounting Spacer is instrumental in the assembly of the crankcase and associated kits. It ensures that all components are aligned correctly, which is essential for the structural integrity and performance of the crankcase.

-

Sense Upfit and Monitor Systems: For sense upfit and engine monitor systems, the Mounting Spacer ensures that sensors and monitoring equipment are positioned accurately. This is important for obtaining precise readings and ensuring the engine operates within specified parameters.

-

Electronic Engine Mounting: In electronic engine systems, the Mounting Spacer plays a role in securing electronic components in place. This ensures that the electronic engine control units (ECUs) and related hardware are mounted correctly, reducing the risk of damage from vibrations.

-

Aftercooler and Mounting: The Mounting Spacer is used in the arrangement of the aftercooler, ensuring that it is mounted securely and aligned properly. This is important for the efficient cooling of the compressed air from the turbocharger.

-

Cense Harness and Oil Connection Parts: When dealing with cense harnesses and oil connection parts, the Mounting Spacer ensures that these components are spaced correctly. This prevents issues such as oil leaks and ensures that the cense harness functions correctly.

-

Performance and Performance Parts: For performance parts and plumbing, the Mounting Spacer ensures that high-performance components are installed with the correct spacing. This is vital for maximizing the performance gains from these parts.

-

Injector and Turbocharger Oil Plumbing: Finally, in the plumbing of injectors and turbocharger oil systems, the Mounting Spacer ensures that all connections are aligned properly. This is essential for the efficient flow of oil and fuel, contributing to the overall performance and reliability of the engine.

Conclusion

The Cummins 3631396 Mounting Spacer is a critical component in the maintenance and operation of heavy-duty trucks and engines. Its role in ensuring proper alignment and spacing between components contributes to the efficiency, reliability, and longevity of the vehicle. Proper installation, regular maintenance, and understanding its compatibility with specific engine models are essential for maximizing the benefits of this part.

-

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Hilgers, M. (2023). Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for M15 CM2670 M107B, Bulletin Number 5659803.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.