This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

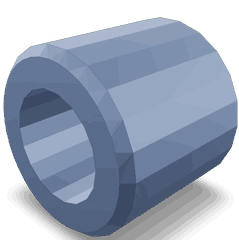

The Cummins 3648201 Mounting Spacer is a component designed to facilitate the proper installation and alignment of various parts within heavy-duty truck engines. Its role is significant in ensuring that components are correctly positioned, which contributes to the overall efficiency and reliability of the truck’s engine system 1.

Basic Concepts of Mounting Spacers

Mounting spacers are mechanical components used to create the necessary distance between two parts, ensuring they are correctly aligned and securely fastened. They play a role in maintaining the structural integrity and operational stability of mechanical systems by providing precise spacing and alignment. This is particularly important in heavy-duty applications where components are subject to significant stress and vibration 2.

Purpose of the 3648201 Mounting Spacer

The 3648201 Mounting Spacer is specifically designed to play a role in the installation and alignment of components within a truck’s engine system. It is positioned between two parts to ensure they are held at the correct distance apart, which is crucial for the proper functioning of the engine. This spacer interacts with other parts to maintain alignment, reduce stress on fasteners, and ensure that components operate within their designed parameters 3.

Key Features

The 3648201 Mounting Spacer is characterized by its material composition, which is typically designed to withstand the harsh conditions found in heavy-duty truck engines. Its dimensions are precisely engineered to provide the exact spacing required for optimal component alignment. The design of the spacer also incorporates features that enhance its performance and durability, such as resistance to wear and corrosion.

Benefits of Using the 3648201 Mounting Spacer

Utilizing the 3648201 Mounting Spacer offers several advantages. It contributes to improved alignment of engine components, which can lead to reduced vibration and enhanced operational stability. Additionally, by ensuring components are correctly spaced and aligned, the spacer plays a role in extending the longevity of the parts it supports, potentially reducing maintenance costs and downtime.

Installation Process

Proper installation of the 3648201 Mounting Spacer involves several steps to ensure it is correctly positioned and secured. It is important to follow manufacturer guidelines for torque specifications and alignment checks to avoid common pitfalls such as over-tightening or misalignment. Careful attention to these details during installation can significantly impact the performance and longevity of the engine components.

Troubleshooting Common Issues

Common issues associated with mounting spacers include misalignment and wear. These problems can often be traced back to incorrect installation or environmental factors. Troubleshooting methods may involve re-evaluating the installation process, checking for signs of wear or damage, and ensuring that all fasteners are properly torqued. Addressing these issues promptly can help maintain the integrity of the engine system.

Maintenance Tips

Regular maintenance of the 3648201 Mounting Spacer is important to ensure its continued performance. This includes periodic inspections for signs of wear, corrosion, or damage. Maintenance intervals should be aligned with the manufacturer’s recommendations or based on the operating conditions of the truck. Early detection of potential issues can prevent more significant problems down the line.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a strong reputation in the heavy-duty truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on reliability make it a preferred choice for many fleet operators and maintenance professionals.

Cummins Engine Part 3648201: Mounting Spacer Compatibility

The Cummins part 3648201, a Mounting Spacer, is designed to fit seamlessly within the engine architecture of several Cummins engines. This part is crucial for ensuring the proper alignment and stability of engine components, contributing to the overall performance and longevity of the engine.

QSK60 and G Engines

The QSK60 and G engines, both known for their robust performance and reliability, utilize the 3648201 Mounting Spacer. This part is integral to the mounting systems of these engines, providing the necessary spacing and support for various engine components. The precision engineering of the 3648201 ensures that these engines operate smoothly and efficiently, maintaining their high standards of performance.

CM2358 and K110 Engines

Similarly, the CM2358 and K110 engines benefit from the use of the 3648201 Mounting Spacer. These engines, which are part of Cummins’ extensive lineup, require this component to maintain the correct positioning of critical parts. The 3648201 Mounting Spacer is engineered to fit these engines perfectly, ensuring that all components are securely and accurately mounted. This precision is vital for the engines’ operational integrity and efficiency.

By integrating the 3648201 Mounting Spacer into their designs, Cummins ensures that these engines perform at their best, providing reliable power and durability in various applications.

Role of Part 3648201 Mounting Spacer in Engine Systems

The part 3648201 Mounting Spacer is integral to the efficient operation and assembly of various engine components. It serves as a precise spacing element that ensures proper alignment and clearance between components, thereby facilitating optimal performance and longevity of the engine system.

Integration with Plumbing Systems

In plumbing systems within engine setups, the Mounting Spacer ensures that pipes and fittings are correctly spaced. This is particularly important for maintaining the integrity of fluid dynamics, preventing leaks, and ensuring that the flow of fluids—whether coolant, fuel, or lubricants—is unimpeded. Proper spacing also reduces the risk of vibrations that could lead to wear and tear over time.

Turbocharger Coolant Systems

When it comes to turbocharger coolant systems, the Mounting Spacer plays a significant role in maintaining the correct distance between the turbocharger and its coolant passages. This ensures that the coolant effectively manages the heat generated by the turbocharger, preventing overheating and potential damage. The spacer helps in securing the coolant lines and connections, ensuring they remain stable under the high pressures and temperatures typical in such systems.

Turbocharger Assembly

In the context of turbocharger assemblies, the Mounting Spacer is used to achieve the correct alignment between the turbocharger and the engine block or manifold. This alignment is essential for the efficient transfer of exhaust gases and the effective operation of the turbocharger. The spacer helps in reducing the stress on the turbocharger mounting points, thereby enhancing the durability and reliability of the turbocharger system.

Water Transfer Connection

For water transfer connections, the Mounting Spacer ensures that the water pump and related components are correctly positioned. This is vital for the efficient circulation of coolant throughout the engine, ensuring that all critical components are adequately cooled. The spacer aids in maintaining the structural integrity of the water transfer system, preventing leaks and ensuring consistent coolant flow.

Conclusion

Overall, the 3648201 Mounting Spacer is a small yet significant component that contributes to the precise assembly and reliable operation of various engine systems. Its role in maintaining proper spacing and alignment is essential for the efficient and durable performance of engine components.

-

Kasab, John, and Andrea Strzelec. Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International, 2020.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ -

Limpert, Rudolf. Brake Design and Safety, Third Edition. SAE International, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.