This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

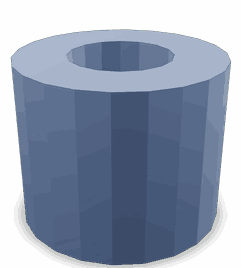

The Cummins 3863317 Mounting Spacer is a critical component in commercial truck operations, designed to enhance the efficiency and reliability of the vehicle’s mechanical system. Understanding its function and role is essential for maintaining and optimizing truck performance.

Basic Concepts of Mounting Spacers

Mounting spacers are mechanical components that create and maintain precise distances between parts within a system. They ensure the stability and proper alignment of components, which is vital for the efficient operation of mechanical systems. By providing necessary spacing, mounting spacers prevent undue stress on parts and contribute to the longevity and performance of the system 1.

Purpose of the Cummins 3863317 Mounting Spacer

The Cummins 3863317 Mounting Spacer is engineered to maintain correct spacing and alignment between components in a truck’s mechanical system. It ensures that parts are positioned accurately relative to each other, which is crucial for the smooth operation of the truck. This spacer helps in distributing loads evenly and reducing the risk of component misalignment, which can lead to increased wear and potential failure 2.

Key Features

The Cummins 3863317 Mounting Spacer is characterized by several key features that enhance its performance and durability. It is made from materials that offer high resistance to wear and corrosion, ensuring longevity in demanding environments. The design specifications of the spacer are tailored to meet the specific requirements of its application, providing a precise fit and function within the truck’s mechanical system 3.

Benefits of Using the 3863317 Mounting Spacer

Utilizing the Cummins 3863317 Mounting Spacer offers several advantages. It contributes to improved component alignment, which is essential for the efficient operation of the truck. The spacer enhances structural integrity by ensuring that parts are held in the correct position, reducing the likelihood of misalignment-related issues. Additionally, it may lead to increases in operational efficiency and the longevity of associated parts by maintaining optimal spacing and alignment.

Installation Considerations

Proper installation of the Cummins 3863317 Mounting Spacer is essential for its effective function. Guidelines and best practices should be followed to ensure that the spacer is correctly positioned and secured. This includes using the necessary tools, adhering to recommended procedures, and being aware of common pitfalls that could compromise the spacer’s performance.

Troubleshooting and Maintenance

Identifying and addressing common issues related to the Cummins 3863317 Mounting Spacer is important for maintaining optimal performance. Signs of wear or damage should be inspected regularly, and maintenance practices should be implemented to ensure the spacer continues to function as intended. This may include cleaning, checking for proper alignment, and replacing the spacer if it shows signs of significant wear or damage.

Manufacturer Overview - Cummins

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of products and commitment to quality and reliability. The company’s history and reputation provide context for the quality and performance of the Cummins 3863317 Mounting Spacer, reflecting Cummins’ dedication to producing components that meet the demanding requirements of commercial truck operations.

Cummins Engine Mounting Spacer 3863317 Compatibility

The Cummins Mounting Spacer part number 3863317 is designed to fit a variety of Cummins engine models. This part is integral in ensuring proper engine mounting and stability, contributing to the overall performance and longevity of the engine. Below is a detailed overview of the engines with which this mounting spacer is compatible:

ISB/ISD Series

- ISB/ISD 4.5 CM2150 B119

- ISB/ISD 6.7 CM2150 SN

The ISB/ISD series engines, particularly the 4.5 and 6.7 variants, utilize the 3863317 mounting spacer to maintain precise alignment and support. These engines are known for their robust performance and are commonly used in heavy-duty applications.

ISB Series

- ISB 5.9 CM2880 B110

The ISB 5.9 CM2880 B110 engine is another model that benefits from the 3863317 mounting spacer. This engine is recognized for its balance of power and efficiency, making it suitable for various industrial and commercial uses.

ISBE Series

- ISBE CM2150

- ISBE4 CM850

The ISBE series engines, including the ISBE CM2150 and ISBE4 CM850, are designed for applications requiring high reliability and performance. The 3863317 mounting spacer ensures these engines are securely mounted, enhancing their operational efficiency.

QSB Series

- QSB 4.5 CM2250 EC

- QSB 4.5 CM850 (CM2850)

- QSB 6.7 CM2250

- QSB 6.7 CM2350 B105

- QSB 6.7 CM850 (CM2850)

- QSB 7 CM2880 B117

The QSB series encompasses a range of engines from 4.5 to 7 liters, each with specific mounting requirements. The 3863317 mounting spacer is compatible with the 4.5, 6.7, and 7-liter variants, ensuring that these engines are properly aligned and supported. This series is known for its versatility and is used in a variety of applications, from agricultural to marine.

By ensuring the correct mounting of these engines, the 3863317 mounting spacer plays a crucial role in maintaining the integrity and performance of Cummins engines across different models and applications.

Role of Part 3863317 Mounting Spacer in Engine Systems

The Part 3863317 Mounting Spacer is integral to the proper functioning and alignment of several key components within engine systems.

Alternator Mounting

In the context of alternator mounting, the Mounting Spacer ensures that the alternator is positioned at the correct distance from the engine block. This spacing is essential for maintaining the proper belt tension, which is vital for the efficient transfer of power from the engine to the alternator. Proper alignment facilitated by the spacer prevents undue stress on the alternator and the drive belt, thereby enhancing the longevity and reliability of the alternator system.

Alternator Support

When it comes to alternator support, the Mounting Spacer plays a role in stabilizing the alternator. By providing a consistent and reliable mounting point, the spacer helps in reducing vibrations that could otherwise be transmitted to the alternator. This stability is important for the smooth operation of the alternator, ensuring that it can generate a consistent electrical output without being adversely affected by engine vibrations.

Water Inlet Connection

In systems where the water inlet connection is nearby, the Mounting Spacer assists in maintaining the correct spatial relationship between the alternator and the water inlet. This is particularly important in ensuring that there is no interference between these components, which could lead to leaks or other forms of malfunction. The spacer helps in keeping the components aligned and separated as intended by the engine design, thus contributing to the overall efficiency and safety of the engine system.

Conclusion

The Cummins 3863317 Mounting Spacer is a vital component in the maintenance and optimization of commercial truck engines. Its role in ensuring proper alignment and spacing of critical components contributes significantly to the efficiency, reliability, and longevity of the engine system. Proper installation, regular maintenance, and understanding its compatibility with various Cummins engine models are essential for maximizing the benefits of this Cummins part.

-

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ -

Klyde, Michael, and Kirk VanGelder. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩ -

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.