3902603

Hydraulic Pump Spacer

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

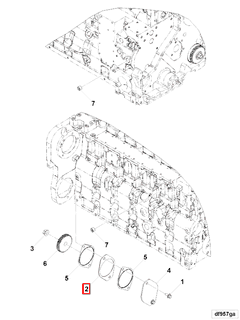

The Hydraulic Pump Spacer, specifically Part #3902603 by Cummins, is a vital component in hydraulic systems, particularly within commercial trucks. This spacer ensures that components are correctly aligned and spaced, contributing to the efficiency and reliability of hydraulic operations 3.

Function and Operation

The Hydraulic Pump Spacer maintains the correct spacing and alignment between components within the hydraulic system, ensuring efficient hydraulic fluid flow and system operation within designed parameters. Proper spacing is essential for the consistent performance of hydraulic pumps and related components, preventing undue stress and potential damage 4.

Purpose of the 3902603 Hydraulic Pump Spacer

This Cummins part ensures that the hydraulic pump and other components are aligned correctly, which is crucial for the system’s efficiency and performance. By maintaining proper spacing, this spacer contributes to the overall reliability of the hydraulic system, ensuring smooth and effective operation 1.

Key Features

The 3902603 Hydraulic Pump Spacer is constructed from durable materials designed to withstand the pressures and conditions within a hydraulic system. Its design specifications are tailored to fit precisely within the hydraulic system, ensuring optimal performance. Additionally, it may possess unique attributes that further improve its effectiveness in maintaining component alignment and spacing 2.

Benefits

The advantages provided by the 3902603 Hydraulic Pump Spacer include improved system reliability and enhanced performance. By ensuring proper alignment and spacing, this spacer helps to prevent common issues associated with hydraulic systems, such as leaks and inefficient operation. Furthermore, its use can lead to potential cost savings for fleet operators by reducing the need for repairs and maintenance 3.

Installation and Maintenance

For the proper installation of the 3902603 Hydraulic Pump Spacer, it is recommended to follow specific procedures and use appropriate tools. This ensures that the spacer is correctly positioned and secured within the hydraulic system. Maintenance tips to ensure the longevity and optimal performance of this spacer include regular inspections for wear or damage and adhering to manufacturer guidelines for system maintenance 4.

Troubleshooting Common Issues

Common problems associated with Hydraulic Pump Spacers can include misalignment or wear, which may lead to system inefficiencies or failures. Troubleshooting these issues involves checking the spacer for proper installation and condition, ensuring that it is correctly aligned and not damaged. Addressing these issues promptly can help maintain the efficiency and reliability of the hydraulic system 1.

Safety Considerations

When working with hydraulic systems and components like the 3902603 Hydraulic Pump Spacer, it is important to observe safety protocols and precautions. This includes ensuring that the system is depressurized before any work is performed and using personal protective equipment. Adhering to these safety measures helps protect personnel and maintain the integrity of the hydraulic system 2.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of products and strong reputation. The company’s history is marked by innovation and quality, with a diverse product portfolio that includes hydraulic components. Cummins’ expertise in manufacturing hydraulic parts, such as the 3902603 Hydraulic Pump Spacer, underscores its commitment to providing reliable and high-performance solutions for the industry 3.

Compatibility with Cummins Engines

The Hydraulic Pump Spacer part number 3902603, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part plays a crucial role in maintaining the proper alignment and spacing between the hydraulic pump and other engine components. Below is a detailed overview of the engines with which this spacer is compatible:

Cummins B Series Engines

- B4.5

- B5.9 G

Cummins 6 Series Engines

- 6B5.9

- 6C8.3

Cummins QSB Series Engines

- QSB3.9 30 CM550

- QSB5.9 30 CM550

- QSB5.9 44 CM550

Cummins QSC Series Engines

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

- QSC9 CM2250/QSL9 CM2250

Cummins QSL Series Engines

- QSL8.9 CM2150 L141

- QSL9 CM2250

- QSL9 CM2350 L102

- QSL9 CM554

- QSL9 CM850 (CM2850)

Cummins ISC Series Engines

- ISC CM554

Cummins ISL Series Engines

- ISL CM554

This comprehensive compatibility ensures that the Hydraulic Pump Spacer 3902603 can be effectively used across a wide range of Cummins engines, providing the necessary support and alignment for optimal engine performance 4.

Role of Part 3902603 Hydraulic Pump Spacer in Engine Systems

The hydraulic pump spacer, part number 3902603, is an essential component in ensuring the proper alignment and operation of various engine systems. Its primary function is to maintain the correct spacing between the hydraulic pump and other components, which is vital for the efficient transfer of power and the reduction of mechanical stress 1.

Integration with the Compressor

In systems where a compressor is utilized, the hydraulic pump spacer ensures that the hydraulic pump is correctly positioned relative to the compressor. This alignment is important for the compressor to operate efficiently, as any misalignment can lead to increased wear and reduced performance. The spacer helps in distributing the load evenly, which is particularly beneficial in high-stress environments 2.

Air System Compatibility

When integrated with air systems, the hydraulic pump spacer plays a role in maintaining the integrity of the air pathways. Proper spacing ensures that there are no obstructions or undue pressure on the air components, which could otherwise lead to inefficiencies or failures in the air system. This is especially relevant in systems where precise air flow is required for optimal performance 3.

Drive System Alignment

In drive systems, the hydraulic pump spacer ensures that the hydraulic pump is correctly aligned with the drive mechanism. This is important for the smooth operation of the drive system, as misalignment can result in increased friction and wear on the drive components. The spacer helps in maintaining the correct distance, which is essential for the longevity and reliability of the drive system 4.

Front Gear Train Accessory

The front gear train accessory relies on the hydraulic pump spacer to ensure that the hydraulic pump is properly spaced from the gear train. This is important for the efficient transfer of power from the hydraulic pump to the gear train. Proper spacing reduces the risk of gear misalignment, which can lead to increased noise, vibration, and ultimately, gear failure 1.

Front Gear Train Accessory Drive

Similarly, in the front gear train accessory drive, the hydraulic pump spacer ensures that the hydraulic pump is correctly positioned in relation to the drive components. This alignment is important for the efficient operation of the drive, as it ensures that power is transferred smoothly without unnecessary stress on the components 2.

Mounting Considerations

The hydraulic pump spacer also plays a role in the mounting of the hydraulic pump. By providing the correct spacing, it ensures that the pump is securely mounted and aligned with other components. This is important for the stability and reliability of the entire system, as improper mounting can lead to vibrations and increased wear on the pump and surrounding components 3.

Conclusion

In summary, the hydraulic pump spacer, part number 3902603, is a key component in maintaining the alignment and efficiency of various engine systems. Its role in ensuring proper spacing between the hydraulic pump and other components is essential for the smooth operation and longevity of the engine system 4.

-

Pacejka, H. B. (2006). Tyre and Vehicle Dynamics. Butterworth-Heinemann.

↩ ↩ ↩ ↩ -

Hilgers, M. (2023). Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature.

↩ ↩ ↩ ↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ ↩ ↩ ↩ ↩ -

Hilgers, M. (2023). Entire Vehicle: Second Edition. Springer Nature.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.