This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

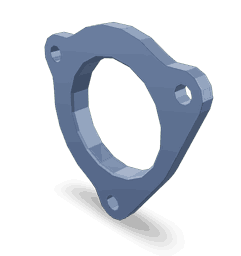

The Cummins 3968179 Starting Motor Spacer is a component designed to facilitate the proper operation of the starting system in heavy-duty trucks. Its purpose is to ensure the correct alignment and spacing between the starter motor and the flywheel, which is vital for the efficient starting of the engine 1.

Function and Operation

The Starting Motor Spacer operates within the starting system by providing the necessary distance between the starter motor and the flywheel. This spacing allows the starter motor to engage the flywheel properly without causing undue stress or misalignment. The spacer interacts with both the starter motor and the flywheel, ensuring that the engagement is smooth and efficient, which is crucial for the reliable starting of the engine 2.

Purpose of the Starting Motor Spacer

The specific role of the Starting Motor Spacer is to maintain the proper alignment and operation of the starter motor. By ensuring that the starter motor is correctly positioned relative to the flywheel, the spacer contributes to the efficient starting of the engine. This alignment is critical for the smooth operation of the starting system and helps to prevent wear and damage to the starter motor and flywheel 3.

Key Features

The Cummins 3968179 Starting Motor Spacer is characterized by several key features that enhance its performance and durability. It is typically made from high-quality materials that can withstand the rigors of heavy-duty truck operation. The design of the spacer includes precise dimensions to ensure accurate alignment, and it may feature unique characteristics such as anti-vibration properties to further enhance its functionality 4.

Benefits

Using the Cummins 3968179 Starting Motor Spacer offers several benefits. It improves the reliability of engine starts by ensuring proper alignment and spacing. This can lead to reduced wear on starter components, as the starter motor engages the flywheel more smoothly. Additionally, the spacer contributes to the enhanced overall performance of the starting system, making it a valuable component for heavy-duty truck applications 5.

Installation Considerations

When installing the Starting Motor Spacer, it is important to follow guidelines and best practices to ensure optimal performance. Proper torque specifications should be adhered to, and careful attention should be paid to the alignment of the spacer between the starter motor and the flywheel. This ensures that the spacer functions as intended and contributes to the efficient operation of the starting system 6.

Troubleshooting Common Issues

Common issues related to the Starting Motor Spacer may include misalignment or wear. If the spacer is not properly aligned, it can lead to inefficient starting and potential damage to the starter motor or flywheel. Regular inspection and maintenance are important to identify and address these issues promptly. Troubleshooting steps may involve checking the alignment, inspecting for signs of wear, and ensuring that the spacer is securely installed 7.

Maintenance Tips

To ensure the long-term performance and reliability of the Starting Motor Spacer, regular maintenance is recommended. This includes keeping the spacer clean and free from debris, which can interfere with its operation. Periodic checks for signs of wear or damage are also important, as these can affect the spacer’s ability to maintain proper alignment and spacing. By following these maintenance tips, the Starting Motor Spacer can continue to contribute to the efficient starting of the engine 8.

Cummins Overview

Cummins Inc. is a well-established company with a strong reputation in the automotive and heavy-duty truck industry. Founded in 1919, Cummins has a long history of innovation and quality in manufacturing automotive components. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to quality and innovation is evident in its product lineup, which includes components like the 3968179 Starting Motor Spacer 9.

Cummins Starting Motor Spacer 3968179 Compatibility

The Cummins Starting Motor Spacer part number 3968179 is designed to fit seamlessly with various engine models, ensuring a secure and reliable connection between the starting motor and the engine. This component is crucial for maintaining the integrity of the starting system and ensuring optimal performance.

Engine Compatibility

- 6C8.3 Engines

The 3968179 Starting Motor Spacer is specifically engineered to fit the 6C8.3 engine series. This part ensures that the starting motor is properly aligned and securely fastened, which is essential for the efficient operation of the engine’s starting system.

Installation and Functionality

When installing the 3968179 Starting Motor Spacer, it is important to follow the manufacturer’s guidelines to ensure proper alignment and secure attachment. This part plays a role in the starting process by maintaining the correct spacing between the starting motor and the engine, which helps to prevent wear and tear on both components.

Importance of Proper Fitment

Using the correct starting motor spacer is vital for the longevity and performance of the engine. An improperly fitted spacer can lead to misalignment, increased wear, and potential failure of the starting motor or engine components. The 3968179 part number is designed to meet the specific requirements of the engines it is intended for, ensuring a precise fit and reliable operation.

Role of Part 3968179 Starting Motor Spacer in Engine Systems

The Part 3968179 Starting Motor Spacer is a component in the assembly and functionality of engine systems, particularly in the integration of the starting motor. This spacer is positioned between the starting motor and the engine block, serving several important functions.

Integration with the Starting Motor

When installing the starting motor, the Part 3968179 Spacer ensures proper alignment and spacing. It maintains the correct distance between the starting motor and the flywheel or flexplate, which is vital for the efficient engagement of the starter gear with the ring gear on the flywheel. This precise spacing allows for smooth and reliable starting of the engine, reducing the risk of gear misalignment or damage.

Mounting Considerations

The spacer also plays a role in the mounting process of the starting motor. It provides a stable and even surface for the starting motor to be bolted onto the engine block. This stability is important for the consistent operation of the starting motor, ensuring that it can deliver the necessary torque to crank the engine without wobbling or shifting.

Enhancing Durability and Performance

By incorporating the Part 3968179 Spacer, the overall durability and performance of the starting system are enhanced. The spacer helps in distributing the load evenly across the mounting points, which can prevent undue stress on the starting motor and the engine block. This even distribution contributes to the longevity of both components and ensures reliable starting performance over time.

Conclusion

In summary, the Part 3968179 Starting Motor Spacer is a key element in the starting system of engine assemblies, facilitating proper alignment, stable mounting, and enhanced durability. Regular maintenance and proper installation are essential to ensure the efficient operation and longevity of this Cummins part.

-

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, author: Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, publisher: Springer, date: 2018

↩ -

Diesel Engine System Design, author: Qianfan Xin, publisher: Woodhead Publishing, date: 2011

↩ -

Bosch Automotive Handbook 9th Edition, author: Robert Bosch GmbH, publisher: Robert Bosch GmbH, date: 2014

↩ -

engine: General Information, bulletinNumber: Bulletin Number 4915909, title: Owners Manual

↩ -

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, author: Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, publisher: Springer, date: 2018

↩ -

Diesel Engine System Design, author: Qianfan Xin, publisher: Woodhead Publishing, date: 2011

↩ -

Bosch Automotive Handbook 9th Edition, author: Robert Bosch GmbH, publisher: Robert Bosch GmbH, date: 2014

↩ -

engine: General Information, bulletinNumber: Bulletin Number 4915909, title: Owners Manual

↩ -

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, author: Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, publisher: Springer, date: 2018

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.