This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

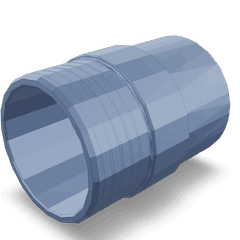

The 4011768 Spacer Connection by Cummins is a specialized component designed for use in commercial trucks. This part plays a role in maintaining the structural integrity and operational efficiency of the truck’s engine system. By ensuring proper alignment and spacing between components, it contributes to the overall performance and longevity of the vehicle.

Basic Concepts of Spacer Connections

Spacer connections are mechanical components used to maintain the correct distance between two or more parts within a system. They play a role in ensuring that components are properly aligned, which can help prevent undue stress and wear. In mechanical systems, spacers contribute to the stability and performance of various components by providing necessary clearance and support 1.

Purpose of the 4011768 Spacer Connection

The 4011768 Spacer Connection is specifically designed to play a role in the operation of commercial trucks by ensuring the proper spacing between engine components. It is typically placed between parts that require precise alignment to function correctly. This spacer connection interacts with other parts to maintain the structural integrity of the engine, facilitating smooth operation and reducing the risk of component failure.

Key Features

The 4011768 Spacer Connection features a durable material composition, often made from high-strength alloys to withstand the rigors of commercial truck operation. Its design specifications include precise dimensions to ensure accurate fitting and function. Unique attributes of this spacer connection may include corrosion-resistant coatings and enhanced load-bearing capabilities, which contribute to its overall functionality and reliability 2.

Benefits

The 4011768 Spacer Connection offers several advantages, including improved performance and durability. By maintaining proper alignment and spacing, it helps ensure that engine components operate efficiently. Additionally, its robust construction reduces the need for frequent replacements, offering cost-effectiveness in maintenance and operation. The spacer connection also contributes to the longevity of the engine by minimizing wear and stress on interconnected parts 3.

Installation Process

Proper installation of the 4011768 Spacer Connection involves several steps to ensure correct fitting and function. Begin by identifying the correct placement between the engine components. Use appropriate tools, such as torque wrenches, to secure the spacer in place. Follow the manufacturer’s guidelines for torque specifications to avoid over-tightening or under-tightening. Ensure that all connections are clean and free of debris before installation to prevent potential issues.

Troubleshooting Common Issues

Common problems associated with spacer connections can include misalignment, wear, and corrosion. Misalignment may result from incorrect installation or component failure, while wear can occur due to prolonged use and exposure to harsh conditions. Corrosion might develop in environments with high moisture or chemical exposure. To resolve these issues, inspect the spacer connection regularly, clean it as necessary, and replace it if significant wear or corrosion is detected.

Maintenance Tips

Regular maintenance of the 4011768 Spacer Connection is vital to ensure its continued performance. Inspection routines should include checking for signs of wear, corrosion, or misalignment. Cleaning the spacer connection and its surrounding components can help prevent buildup and ensure smooth operation. Consider replacement if the spacer shows significant signs of damage or if it no longer maintains proper alignment between components.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions systems. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company’s extensive product range and commitment to customer satisfaction make it a trusted name among fleet operators and maintenance professionals.

Cummins Engine Spacer Connection Part 4011768

The Cummins Spacer Connection part 4011768 is a critical component designed to fit seamlessly with several Cummins engine models. This part is essential for maintaining the structural integrity and operational efficiency of the engines it is used with.

QSV81G and QSV91G Engines

The Spacer Connection part 4011768 is compatible with both the QSV81G and QSV91G engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The part ensures proper spacing and alignment between various engine components, contributing to the overall smooth operation and longevity of these engines.

QSW/QSV82 Engines

For the QSW/QSV82 engines, the part 4011768 is engineered to fit precisely, ensuring that the engine’s components remain correctly positioned. This is particularly important in maintaining the engine’s efficiency and preventing potential wear and tear that could arise from misalignment.

QSW73 Engine

The QSW73 engine also benefits from the use of the Spacer Connection part 4011768. This part plays a crucial role in maintaining the engine’s structural integrity, ensuring that all components function as intended without undue stress or misalignment.

In summary, the Cummins Spacer Connection part 4011768 is a versatile and essential component for the QSV81G, QSV91G, QSW/QSV82, and QSW73 engines, ensuring optimal performance and longevity.

Role of Part 4011768 Spacer Connection in Engine Systems

The part 4011768 Spacer Connection is integral to the efficient operation and assembly of various engine components. It ensures proper spacing and alignment between components, which is essential for the overall functionality and performance of the engine.

Integration with Engine Components

-

Aid and Coolant Heater Starting System: The Spacer Connection is used to maintain the correct distance between the coolant heater and the engine block. This ensures that the heater can effectively warm the coolant before it circulates through the engine, aiding in quicker engine starts, especially in colder climates.

-

Drive and Front Gear Train Accessory: In the drive system, the Spacer Connection helps in aligning the front gear train accessory with the engine’s drive mechanism. Proper spacing ensures smooth operation and reduces the risk of mechanical wear or failure.

-

Flanged Pipe Adapter: When connecting the flanged pipe adapter to the engine, the Spacer Connection ensures that the adapter is positioned correctly. This is vital for maintaining the integrity of the coolant or fuel lines, preventing leaks, and ensuring efficient flow.

-

Gear Assembly Housing: Within the gear assembly, the Spacer Connection plays a role in maintaining the precise distance between gears. This is important for the synchronized operation of the gear assembly, which in turn affects the overall performance of the engine.

-

Water Inlet Connection: The Spacer Connection is used to ensure that the water inlet connection is properly spaced from the engine block. This is essential for the efficient entry of coolant into the engine, which is crucial for temperature regulation.

-

Water Outlet Tube: Similarly, at the water outlet, the Spacer Connection ensures that the tube is correctly aligned and spaced. This aids in the smooth exit of coolant from the engine, helping to maintain optimal engine temperature.

-

Water Transfer Tube: In systems where water transfer tubes are used, the Spacer Connection ensures that these tubes are properly positioned. This is important for the effective transfer of coolant between different parts of the engine, contributing to consistent engine cooling 4.

Conclusion

The 4011768 Spacer Connection by Cummins is a vital component in the maintenance and operation of commercial truck engines. Its role in ensuring proper spacing and alignment between engine components contributes to the overall efficiency, performance, and longevity of the engine. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann.

↩ -

Crolla, D. (2015). Crolla Encyclopedia. Wiley.

↩ -

Eret, A. (2024). Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.