This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4014688 Mounting Spacer is a component designed to ensure proper spacing and alignment between various parts in heavy-duty truck systems. Its role is significant in maintaining the structural integrity and operational efficiency of the truck’s mechanical systems.

Basic Concepts of Mounting Spacers

Mounting spacers are mechanical components used to create and maintain specific distances between parts within a system. They play a role in ensuring that components are correctly aligned, which is vital for the stability and performance of mechanical assemblies. By providing the necessary separation, mounting spacers help prevent undue stress on parts, reduce the risk of misalignment, and contribute to the overall durability of the system 1.

Purpose of the 4014688 Mounting Spacer

The Cummins 4014688 Mounting Spacer is specifically designed to maintain proper spacing and alignment between components in heavy-duty trucks. It ensures that parts are positioned correctly relative to each other, which is crucial for the efficient operation of the truck. This spacer helps in distributing loads evenly and preventing excessive wear on connected parts.

Key Features

The Cummins 4014688 Mounting Spacer is characterized by several key features that enhance its performance and durability. It is made from high-quality materials that offer resistance to wear and corrosion. The spacer’s dimensions are precisely engineered to fit specific applications, ensuring optimal performance. Its design includes features that facilitate easy installation and removal, contributing to its overall effectiveness in heavy-duty environments.

Benefits of Using the 4014688 Mounting Spacer

Utilizing the Cummins 4014688 Mounting Spacer offers several advantages. It contributes to improved component alignment, which can lead to reduced wear and tear on mechanical parts. Additionally, proper spacing provided by the spacer enhances the overall efficiency of the system, ensuring that components operate within their designed parameters. This can result in longer component lifespan and reduced maintenance requirements 2.

Installation Process

Installing the Cummins 4014688 Mounting Spacer involves several steps to ensure proper fit and function. Begin by identifying the correct location for the spacer within the truck’s system. Carefully clean the mounting surfaces to remove any debris or contaminants that could affect alignment. Place the spacer in position, ensuring it is aligned correctly with the surrounding components. Secure the spacer in place according to the manufacturer’s instructions, taking care to avoid over-tightening, which could damage the spacer or adjacent parts.

Troubleshooting Common Issues

Common issues associated with mounting spacers include misalignment, excessive wear, and failure. To address misalignment, verify that the spacer is correctly positioned and that all surrounding components are properly aligned. Excessive wear may indicate that the spacer is not providing adequate support or that there is an issue with the load distribution. In such cases, inspecting the spacer for damage and ensuring it is the correct size for the application can help resolve the problem. Failure of the spacer may require replacement with a new, correctly sized spacer.

Maintenance Tips

Regular maintenance of the Cummins 4014688 Mounting Spacer is important to ensure its continued effectiveness. Inspect the spacer during routine maintenance checks for signs of wear, corrosion, or damage. Clean the spacer and surrounding areas to remove any buildup that could affect performance. If the spacer shows significant wear or damage, consider replacing it to maintain the integrity of the system.

Compatibility and Applications

The Cummins 4014688 Mounting Spacer is designed for use in specific applications within various truck models and systems. It is important to verify compatibility with the truck’s make and model to ensure proper fit and function. Consulting the manufacturer’s guidelines or a professional technician can provide clarity on the spacer’s applications and any specific compatibility considerations.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of various applications 3.

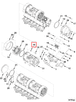

Role of Part 4014688 Mounting Spacer in Engine Systems

The Cummins part 4014688, a Mounting Spacer, is integral to the assembly of several engine models. This part is specifically designed to ensure proper alignment and secure mounting of engine components, contributing to the overall stability and performance of the engine.

For the QSV91-G4 CM558/CM700 V102 engine, the Mounting Spacer 4014688 plays a role in maintaining the integrity of the engine’s mounting system. It ensures that the engine is securely fastened to its mounting points, reducing vibrations and enhancing the engine’s operational efficiency.

Similarly, in the QSV91G engine, the part 4014688 is essential for the same purpose. It provides the necessary spacing and support, ensuring that the engine components are correctly positioned and securely fastened. This helps in maintaining the engine’s structural integrity and operational performance.

In both engine models, the use of the Cummins part 4014688 is important for the proper functioning of the engine. It ensures that the engine is mounted correctly, which is vital for the engine’s longevity and performance.

Conclusion

The Cummins 4014688 Mounting Spacer is a critical component in heavy-duty truck systems, ensuring proper spacing and alignment of engine components. Its high-quality construction, precise engineering, and ease of installation contribute to the overall efficiency and durability of the system. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.