This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4096027 Mounting Spacer is a component designed for use in heavy-duty truck applications. Its primary role is to ensure proper alignment and spacing between various components within the truck’s engine system. This part is integral to maintaining the structural integrity and operational efficiency of the engine, contributing to the overall performance and longevity of the vehicle 1.

Purpose and Function

The mounting spacer serves a vital function in truck applications by maintaining the correct alignment and spacing between engine components. This ensures that parts operate within their designed parameters, reducing the risk of misalignment, which can lead to increased wear, decreased efficiency, and potential failure of components. By providing a stable and consistent gap between parts, the mounting spacer helps to distribute loads evenly and prevent undue stress on individual components 2.

Key Features

The Cummins 4096027 Mounting Spacer is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to wear and corrosion. The spacer is designed with precise dimensions to fit snugly between components, providing a reliable and consistent spacing solution. Additionally, its design incorporates features that facilitate easy installation and removal, making it a practical choice for maintenance and repair scenarios 3.

Benefits

Utilizing the Cummins 4096027 Mounting Spacer offers several benefits. It contributes to improved component alignment, which is crucial for the efficient operation of the engine. By maintaining proper spacing, the spacer helps to reduce wear and tear on engine components, leading to extended service life. Furthermore, the enhanced alignment and spacing provided by the mounting spacer can contribute to the overall performance of the truck, ensuring that the engine operates smoothly and efficiently.

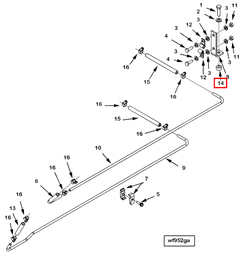

Installation Process

Proper installation of the Cummins 4096027 Mounting Spacer is critical to its effectiveness. The process involves several steps to ensure optimal performance. First, the area where the spacer will be installed should be cleaned to remove any debris or old components. The spacer should then be positioned between the designated components, ensuring it is aligned correctly. It is important to follow the manufacturer’s guidelines for torque specifications when securing the spacer in place to avoid over-tightening, which could damage the spacer or the components it is installed between.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 4096027 Mounting Spacer is important to ensure its continued effectiveness. This includes periodic inspection for signs of wear, corrosion, or damage. If any issues are detected, they should be addressed promptly to prevent further deterioration. Common problems may include misalignment or spacing issues, which can often be resolved by re-positioning or replacing the spacer. Regular cleaning and lubrication, where applicable, can also help to maintain the spacer’s performance.

Manufacturer Information

Cummins Inc. is a renowned manufacturer with a long-standing reputation in the automotive and heavy-duty truck industries. The company is known for its commitment to quality, innovation, and customer satisfaction. Cummins components, including the 4096027 Mounting Spacer, are designed and manufactured to meet rigorous standards, ensuring reliability and performance in demanding applications. The company’s dedication to research and development drives continuous improvement in its product offerings, making Cummins a trusted name in the industry.

Role of Part 4096027 Mounting Spacer in Engine Systems

Engine Control Module (ECM) Mounting

The 4096027 Mounting Spacer is employed to maintain the correct distance between the Engine Control Module (ECM) and other adjacent components. This spacing is vital for thermal management, as it allows for adequate airflow around the ECM, preventing overheating. Additionally, it ensures that the ECM is securely mounted, reducing the risk of vibration-induced damage.

Corrosion Resistor Integration

When integrating corrosion resistors within the engine system, the 4096027 Mounting Spacer plays a significant role. It helps in positioning the resistors at optimal distances from heat sources and other electrical components. This not only enhances the performance of the resistors but also prolongs their lifespan by minimizing exposure to corrosive elements and excessive heat.

Plumbing and Fluid Management

In plumbing applications within the engine system, the 4096027 Mounting Spacer assists in maintaining the correct alignment of pipes and fittings. This ensures that fluid flow is unimpeded and that there are no leaks or restrictions in the system. Proper spacing also aids in the efficient distribution of coolants and lubricants, which are essential for the engine’s operation.

General Mounting Applications

Across various mounting applications, the 4096027 Mounting Spacer is used to achieve precise alignment and spacing. Whether it is mounting sensors, actuators, or other critical components, this spacer ensures that all parts are correctly positioned. This not only enhances the performance of individual components but also contributes to the overall reliability and efficiency of the engine system.

Conclusion

The Cummins 4096027 Mounting Spacer is a vital component in the assembly and operation of various engine systems. Its role in ensuring proper spacing and alignment between components is essential for the efficient functioning of the engine. Whether used in ECM mounting, corrosion resistor integration, plumbing applications, or general mounting scenarios, this part contributes significantly to the performance, reliability, and longevity of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.