4101256

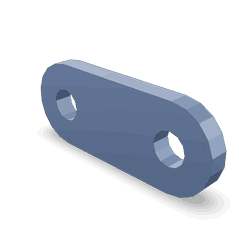

Mounting Spacer

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4101256 Mounting Spacer is a specialized component designed for use in heavy-duty truck assemblies. Its purpose is to provide the necessary spacing and alignment between various mechanical components, ensuring optimal performance and longevity of the truck’s engine or transmission system. Understanding the role and significance of this part is vital for maintaining the efficiency and reliability of heavy-duty vehicles.

Basic Concepts of Mounting Spacers

Mounting spacers are mechanical components used to create distance between two parts in an assembly. They play a role in maintaining the correct alignment and stability of components, which is important for the proper functioning of mechanical systems. By ensuring that parts are positioned accurately relative to each other, mounting spacers help to distribute loads evenly and reduce the risk of misalignment, which can lead to increased wear and potential failure of components 1.

Purpose of the Cummins 4101256 Mounting Spacer

The Cummins 4101256 Mounting Spacer is specifically designed to facilitate the mounting of engines or transmissions in heavy-duty trucks. It plays a role in the assembly by providing the precise spacing required between the engine or transmission and the truck’s frame or other supporting structures. This ensures that the components are aligned correctly, which is important for the efficient operation of the vehicle. The spacer also helps in managing the distribution of vibrational forces, contributing to the overall stability and performance of the truck 2.

Key Features

The Cummins 4101256 Mounting Spacer is characterized by several key features that enhance its functionality. These include its material composition, which is selected for durability and resistance to the harsh conditions encountered in heavy-duty applications. The dimensions of the spacer are engineered to meet specific requirements for spacing and alignment in truck assemblies. Additionally, the spacer is designed to handle significant load-bearing capacities, ensuring it can support the weight and dynamic forces of the engine or transmission without deformation or failure 3.

Benefits of Using the Cummins 4101256 Mounting Spacer

Incorporating the Cummins 4101256 Mounting Spacer into truck assemblies offers several advantages. It contributes to improved vibration damping, which helps in reducing the stress on connected components and enhancing the smoothness of operation. The spacer also plays a role in ensuring enhanced component alignment, which is important for the efficient transfer of power and reduction of wear. Furthermore, the durable construction of the spacer increases the overall durability of the truck’s engine or transmission mounting system, leading to longer service life and reduced maintenance requirements.

Installation Considerations

Proper installation of the Cummins 4101256 Mounting Spacer is important for ensuring its effectiveness and the reliability of the truck’s engine or transmission system. Installation procedures should include checking torque specifications to ensure that the spacer is secured correctly without overtightening, which could lead to damage. Alignment checks are also important to verify that the spacer is positioned correctly and that the components it separates are aligned as intended. Compatibility with other components should be confirmed to ensure a proper fit and function within the assembly.

Troubleshooting and Maintenance

Common issues with mounting spacers can include wear, deformation, or misalignment, which may arise due to operational stress or improper installation. Diagnostic steps for identifying problems with the Cummins 4101256 Mounting Spacer involve inspecting the spacer for signs of damage or wear, checking the alignment of connected components, and ensuring that the spacer is securely installed. Maintenance practices to ensure the longevity and performance of the spacer include regular inspections for wear or damage, proper re-torquing as needed, and replacement of the spacer if it shows signs of significant wear or failure.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. The company’s extensive product range includes engines, powertrain components, and aftermarket parts, all of which are designed to meet the demanding requirements of heavy-duty applications. The Cummins 4101256 Mounting Spacer, as part of this product range, benefits from the company’s commitment to quality and performance, ensuring it meets the high standards expected in the industry.

Cummins Engine Mounting Spacer 4101256 Compatibility

The Cummins Mounting Spacer part number 4101256 is designed to fit seamlessly with several of the company’s engine models. This part is crucial for ensuring proper engine alignment and stability, contributing to the overall performance and longevity of the engine.

QSK45 CM500 and QSK60 CM500

The Mounting Spacer 4101256 is compatible with both the QSK45 CM500 and QSK60 CM500 engines. These engines are part of Cummins’ QSK series, known for their robust design and efficiency. The spacer ensures that the engine components are correctly positioned, reducing wear and tear and enhancing operational efficiency.

QSK60 CM850 MCRS and QSK78 CM500

Similarly, the QSK60 CM850 MCRS and QSK78 CM500 engines also utilize the Mounting Spacer 4101256. The QSK60 CM850 MCRS is a high-performance engine designed for demanding applications, while the QSK78 CM500 is another variant in the QSK series, offering a balance of power and reliability. The spacer’s role in these engines is to maintain precise alignment, which is critical for the engines’ performance and durability.

Role of Part 4101256 Mounting Spacer in Engine Systems

In the orchestration of engine components, the 4101256 Mounting Spacer assumes a significant role, particularly in relation to the Drive and Fan systems.

Interaction with the Drive System

The Drive system, which encompasses the crankshaft, pulleys, and belts, relies on precise alignment and spacing to function effectively. The 4101256 Mounting Spacer is instrumental in maintaining the correct distance between the drive components. This ensures that the belts run true and the pulleys engage without undue stress or slippage. By providing the necessary spacing, the Mounting Spacer helps in reducing wear and tear on the drive components, thus contributing to the longevity and efficiency of the engine’s drive system.

Contribution to the Fan System

In the Fan system, which includes the fan blades, fan hub, and associated mounting brackets, the 4101256 Mounting Spacer plays a key role in ensuring optimal airflow and cooling efficiency. Proper spacing is essential for the fan to operate within its designed parameters, allowing it to draw in the required volume of air to cool the engine effectively. The Mounting Spacer ensures that the fan is mounted at the correct distance from other components, preventing interference and allowing for unimpeded airflow. This is particularly important in high-performance engines where cooling demands are greater.

Overall Impact on Engine Performance

By facilitating correct spacing and alignment in both the Drive and Fan systems, the 4101256 Mounting Spacer contributes to the overall performance and reliability of the engine. It ensures that these systems operate within their designed specifications, thereby enhancing the engine’s efficiency, durability, and cooling capabilities.

Conclusion

The Cummins 4101256 Mounting Spacer is a critical component in the assembly and operation of heavy-duty truck engines. Its role in providing precise spacing and alignment between components ensures the efficient and reliable operation of the engine and transmission systems. By understanding and properly utilizing this Cummins part, vehicle operators and maintenance professionals can enhance the performance, durability, and maintenance efficiency of heavy-duty trucks.

-

The Motor Vehicle, TK Garrett, K Newton, W Steeds, Reed Educational and Professional Publishing Ltd, 2001

↩ -

Offroad Vehicle Dynamics Analysis Modelling and Optimization, Hamid Taghavifar and Aref Mardani, Springer, 2017

↩ -

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.