This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

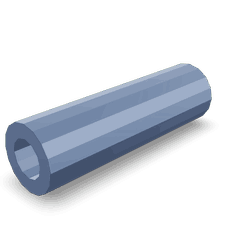

The 4922601 Mounting Spacer, a component manufactured by Cummins, is designed for use in commercial trucks. This part plays a role in ensuring the proper functioning and longevity of the vehicle’s mechanical systems 1.

Basic Concepts of Mounting Spacers

Mounting spacers are mechanical components used to create and maintain specific distances between parts within an assembly. They contribute to the stability and alignment of components by providing a consistent gap, which is important for the proper operation of mechanical systems 2. In commercial trucks, mounting spacers help ensure that components are correctly positioned relative to each other, which can affect performance, efficiency, and durability.

Purpose of the 4922601 Mounting Spacer

The 4922601 Mounting Spacer is specifically designed to maintain proper spacing and alignment between components in a truck’s mechanical system. By ensuring that parts are correctly spaced, this Cummins part helps to facilitate smooth operation, reduce the risk of component misalignment, and contribute to the overall efficiency and reliability of the truck 3.

Key Features

The 4922601 Mounting Spacer boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring it can withstand the rigors of commercial truck operation. The spacer’s dimensions are precisely engineered to fit specific applications, and its design includes features that promote easy installation and long-term reliability.

Benefits

The use of the 4922601 Mounting Spacer offers several benefits. It contributes to improved component alignment, which can lead to reduced wear and tear on mechanical parts. Additionally, by maintaining proper spacing, this spacer helps enhance the overall performance and efficiency of the truck’s mechanical system, potentially leading to longer component lifespans and reduced maintenance needs.

Installation Process

Installing the 4922601 Mounting Spacer requires careful attention to detail to ensure proper fit and function. The process involves cleaning the installation area, positioning the spacer correctly between components, and securing it in place. It is important to follow manufacturer guidelines to avoid common pitfalls such as incorrect alignment or over-tightening, which can affect performance and durability.

Troubleshooting Common Issues

Common issues with the 4922601 Mounting Spacer may include misalignment or wear over time. Troubleshooting these problems involves inspecting the spacer and surrounding components for signs of damage or incorrect installation. Addressing these issues may require realigning components, replacing worn parts, or adjusting the installation to ensure proper fit and function.

Maintenance Tips

Regular maintenance of the 4922601 Mounting Spacer is important for ensuring its continued performance and durability. This includes periodic inspections for signs of wear or damage, cleaning the spacer and surrounding areas to prevent buildup of debris, and replacing the spacer if it shows significant signs of wear or if it no longer maintains proper spacing between components.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and customer satisfaction in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles.

Role of Part 4922601 Mounting Spacer in Engine Systems

The 4922601 Mounting Spacer is integral to the proper assembly and function of various engine components. When integrating a turbocharger into an engine arrangement, the mounting spacer ensures precise alignment and secure attachment of the turbocharger to the engine block. This alignment is essential for the efficient operation of the turbocharger, allowing it to spin at high speeds without causing undue stress on the engine components 4.

In the context of an exhaust transfer kit, the mounting spacer plays a role in maintaining the correct spacing between the exhaust manifold and the turbocharger. This ensures that the exhaust gases flow smoothly into the turbocharger, optimizing its performance and efficiency. Proper spacing also prevents potential leaks and reduces the risk of damage to surrounding components due to excessive vibration or misalignment.

When considering the plumbing aspects of engine systems, the 4922601 Mounting Spacer aids in the accurate installation of oil and coolant lines to the turbocharger. This is vital for the lubrication and cooling of the turbocharger, which are necessary to prevent overheating and ensure longevity. The spacer helps in maintaining the correct distances and angles for these lines, facilitating a secure and leak-free connection.

In upfit kits, which often involve retrofitting additional components to an engine, the mounting spacer ensures that new turbochargers or other aftermarket parts are correctly positioned. This is particularly important in maintaining the balance and harmony of the engine’s overall performance, as improper installation can lead to decreased efficiency and potential damage.

Conclusion

Overall, the 4922601 Mounting Spacer is a key component in the successful integration and operation of turbochargers and related engine systems, ensuring that all parts work together seamlessly for optimal performance.

-

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Cummins Inc. (n.d.). General Information, Bulletin Number 3666117, Operation and Maintenance Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.