This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3044916 Mounting Spacer is a critical component in commercial truck operations, designed to ensure proper spacing and alignment between various mechanical components within the engine system. This part is essential for maintaining the correct positional relationships between parts, which is vital for optimal engine performance and reliability 1.

Basic Concepts of Mounting Spacers

Mounting spacers are mechanical components used to create and maintain specific distances between parts in a system. They ensure that components are correctly aligned and spaced, which is important for the stability and functionality of the mechanical system. By providing the necessary gap, mounting spacers help prevent components from coming into direct contact, which could lead to wear, misalignment, or other operational issues 2.

Purpose of the 3044916 Mounting Spacer

The Cummins 3044916 Mounting Spacer is specifically designed to maintain proper spacing and alignment between components in a truck’s engine system. It ensures that parts are positioned correctly relative to each other, which is important for the efficient operation of the engine. This spacer helps in reducing the potential for component interference and ensures that the engine operates within its designed parameters 3.

Key Features

The Cummins 3044916 Mounting Spacer is characterized by several key features that enhance its performance and durability. It is made from high-quality materials that provide resistance to wear and corrosion. The spacer is designed with precise dimensions to ensure accurate spacing and alignment. Additionally, its design includes features that facilitate easy installation and removal, making it a practical choice for maintenance and repair operations.

Benefits of Using the 3044916 Mounting Spacer

Using the Cummins 3044916 Mounting Spacer offers several advantages. It contributes to improved component alignment, which is important for the smooth operation of the engine. The spacer helps in reducing vibration by maintaining consistent spacing between parts, which can lead to a more stable and reliable engine performance. Additionally, the use of this spacer enhances the overall system reliability by preventing component interference and wear.

Installation Considerations

When installing the Cummins 3044916 Mounting Spacer, it is important to follow guidelines and best practices to ensure proper functionality. This includes adhering to torque specifications to secure the spacer in place without over-tightening, which could lead to damage. Alignment checks should be performed to confirm that the spacer is correctly positioned and that the components it separates are properly aligned. Compatibility with other components should also be verified to ensure seamless integration into the engine system.

Troubleshooting Common Issues

Common issues associated with mounting spacers may include misalignment or wear over time. To address these problems, it is important to perform regular inspections to identify any signs of damage or improper positioning. If misalignment is detected, re-alignment procedures should be followed to correct the issue. In cases of significant wear, replacement of the spacer may be necessary to maintain optimal performance.

Maintenance Tips

To ensure the longevity and performance of the Cummins 3044916 Mounting Spacer, regular maintenance is recommended. This includes inspecting the spacer at routine intervals for signs of wear or damage. Cleaning the spacer and surrounding components can help prevent the buildup of debris that may affect its function. Additionally, following manufacturer guidelines for replacement can help maintain the integrity of the engine system.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its comprehensive range of engine and power generation products. With a history of innovation and quality, Cummins has built a reputation for reliability and performance. The company’s product portfolio includes a variety of components and systems designed to meet the demanding requirements of commercial truck operations, ensuring that vehicles operate efficiently and reliably.

Cummins Mounting Spacer 3044916 Compatibility

The Cummins Mounting Spacer part number 3044916 is designed to fit a variety of Cummins engines, ensuring proper alignment and stability during operation. This part is crucial for maintaining the integrity of the engine’s mounting system, which affects overall performance and longevity.

N14 CELECT and N14 MECHANICAL Engines

The N14 CELECT and N14 MECHANICAL engines both benefit from the use of the 3044916 Mounting Spacer. These engines, known for their robust design and reliability, require precise mounting components to function optimally. The spacer ensures that the engine remains securely attached to its mounting points, reducing vibrations and wear.

NH/NT 855 Engine

The NH/NT 855 engine is another model that utilizes the 3044916 Mounting Spacer. This engine is recognized for its versatility and power, often used in heavy-duty applications. The spacer plays a critical role in maintaining the structural integrity of the engine, ensuring that it operates smoothly and efficiently under various conditions.

QSN14 CM876 N103 Engine

The QSN14 CM876 N103 engine also incorporates the 3044916 Mounting Spacer in its design. This engine is engineered for high-performance applications, demanding precise and reliable mounting components. The spacer helps to stabilize the engine, preventing misalignment and enhancing overall performance.

By using the 3044916 Mounting Spacer, these engines can achieve optimal performance and longevity, thanks to the precise fit and reliable construction of the part.

Role of Part 3044916 Mounting Spacer in Engine Systems

The part 3044916 Mounting Spacer is an integral component in ensuring the proper alignment and spacing between various engine components. Its application is particularly significant in the following areas:

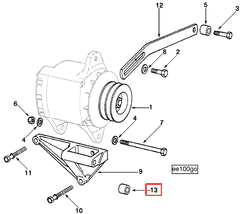

Alternator Mounting

In alternator mounting systems, the 3044916 Mounting Spacer ensures that the alternator is positioned at the correct distance from the engine block. This spacing is essential for maintaining the efficiency of the alternator’s operation, allowing it to spin freely without interference from adjacent components. Proper alignment facilitated by the spacer also ensures that the drive belt tension remains optimal, which is vital for the alternator’s performance and longevity.

Guard

When integrated with guard systems, the 3044916 Mounting Spacer plays a role in maintaining the structural integrity of the guard. It ensures that the guard is held at the correct distance from the engine, providing adequate protection without obstructing the movement of other components. This is particularly important in high-vibration environments where the guard must remain securely in place to protect sensitive engine parts.

Front Engine

In front engine configurations, the 3044916 Mounting Spacer is used to maintain the precise alignment of components such as the crankshaft and camshaft. This alignment is essential for the smooth operation of the engine, reducing wear and tear on moving parts. The spacer helps in distributing loads evenly, which contributes to the overall stability and performance of the engine.

Guard Damper Mounting

For guard damper mountings, the 3044916 Mounting Spacer ensures that the damper is correctly positioned to absorb vibrations effectively. This is important for maintaining the balance and stability of the engine, particularly in high-performance applications where vibrations can significantly impact engine reliability and efficiency. The spacer allows for fine-tuning of the damper’s position, optimizing its performance in reducing engine vibrations.

Conclusion

The Cummins 3044916 Mounting Spacer is a vital component in the maintenance and operation of commercial truck engines. Its role in ensuring proper spacing and alignment between engine components contributes to the overall efficiency, reliability, and longevity of the engine system. Regular maintenance and adherence to installation guidelines are essential to maximize the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.