This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

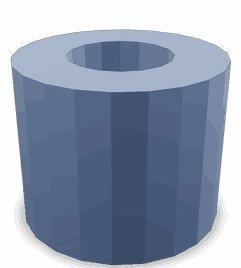

The Cummins 3050395 Mounting Spacer is a component designed for use in commercial trucks. Its primary role is to ensure proper spacing and alignment between various mechanical components within the truck’s engine system. This part is integral to maintaining the structural integrity and operational efficiency of the truck’s engine.

Basic Concepts of Mounting Spacers

Mounting spacers are mechanical components used to create and maintain specific distances between parts within a system. They play a role in ensuring that components are correctly aligned and spaced, which is vital for the stability and performance of the system. By providing the necessary separation, mounting spacers help prevent components from coming into direct contact, which could lead to wear, misalignment, or failure 1.

Purpose of the 3050395 Mounting Spacer

The 3050395 Mounting Spacer is specifically designed to maintain the correct spacing and alignment between components in a truck’s engine. This ensures that parts operate within their designed parameters, reducing the risk of mechanical issues and enhancing the overall efficiency of the engine system. Proper spacing and alignment are key to the longevity and performance of the engine components 2.

Key Features

The 3050395 Mounting Spacer is constructed from high-quality materials that offer durability and resistance to wear. Its dimensions are precisely engineered to fit specific applications, ensuring optimal performance. The design of the spacer includes features that enhance its ability to withstand the rigors of commercial truck operation, such as resistance to vibration and extreme temperatures.

Benefits of Using the 3050395 Mounting Spacer

Utilizing the 3050395 Mounting Spacer offers several advantages. It contributes to improved component alignment, which can lead to reduced wear and tear on engine parts. Additionally, by maintaining proper spacing, the spacer helps enhance the overall efficiency of the engine system, potentially leading to better fuel economy and reduced maintenance costs 3.

Installation Process

Installing the 3050395 Mounting Spacer requires careful attention to ensure correct placement and function. The process involves identifying the correct location for the spacer within the engine system, using the appropriate tools to secure it in place, and verifying that it is properly aligned with adjacent components. Following manufacturer guidelines for installation is recommended to ensure the spacer functions as intended.

Troubleshooting Common Issues

Common issues with the 3050395 Mounting Spacer may include misalignment or wear. To address these problems, it is important to inspect the spacer and surrounding components for signs of damage or improper installation. Correcting any issues with alignment or replacing a worn spacer can help restore the engine system’s performance.

Maintenance Tips

Regular maintenance of the 3050395 Mounting Spacer is important for ensuring continued optimal performance. This includes periodic inspections for signs of wear or damage, cleaning the spacer and surrounding areas to prevent buildup of debris, and replacing the spacer when necessary to maintain proper spacing and alignment.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on reliability make it a preferred choice for commercial vehicle operators and manufacturers.

Cummins Engine Part 3050395: Mounting Spacer Compatibility

The Cummins part 3050395, a Mounting Spacer, is designed to fit seamlessly within a variety of Cummins engine models. This part is crucial for ensuring proper alignment and stability of engine components, contributing to the overall performance and longevity of the engine.

N14 G and N14 MECHANICAL Engines

The N14 G and N14 MECHANICAL engines both benefit from the precise fit of the 3050395 Mounting Spacer. This part is engineered to provide the necessary support and alignment for these engines, ensuring that all moving parts operate smoothly and efficiently. The use of this spacer helps in maintaining the structural integrity of the engine, reducing wear and tear, and preventing potential mechanical failures.

NH/NT 855 Engine

The NH/NT 855 engine also incorporates the 3050395 Mounting Spacer to achieve optimal performance. This engine model, known for its robust design and reliability, relies on the accuracy of the spacer to maintain the alignment of critical engine components. The spacer’s role in this engine is to ensure that the engine operates within its designed parameters, enhancing its operational efficiency and durability.

QSNT14 CM876 N102 Engine

The QSNT14 CM876 N102 engine is another model that utilizes the 3050395 Mounting Spacer. This engine, which is part of the Cummins QSN series, is designed for heavy-duty applications and requires precise engineering components to perform at its best. The spacer plays a vital role in maintaining the alignment and stability of the engine, ensuring that it can handle the demands of its intended use without compromising on performance or reliability.

Each of these engines, despite their differences, relies on the 3050395 Mounting Spacer to provide the necessary support and alignment for their operation. This part’s compatibility across these models underscores its importance in the Cummins engine ecosystem, highlighting its role in maintaining the performance and longevity of these engines.

Role of Part 3050395 Mounting Spacer in Engine Systems

The part 3050395 Mounting Spacer is an essential component in the assembly and maintenance of various engine systems. It facilitates the proper alignment and spacing between components, ensuring optimal performance and longevity of the engine.

Integration with Base Parts

When installing base parts, the Mounting Spacer ensures that components are positioned correctly relative to each other. This precise alignment is vital for the efficient operation of the engine, reducing wear and tear on moving parts.

EBM: Pump Systems

In EBM (Electrically Driven Bilge Pump) systems, the Mounting Spacer plays a significant role in maintaining the structural integrity of the pump assembly. It helps in securing the pump to the engine frame, ensuring that vibrations are minimized during operation.

Water Pump Assemblies

For water pump assemblies, the Mounting Spacer is used to maintain the correct distance between the pump and other adjacent components. This is particularly important in systems where the water pump is paired with an idler pulley or manifold, as improper spacing can lead to inefficient cooling and increased mechanical stress.

Idler Pulley and Shaft Mounting

In systems involving an idler pulley and idler shaft mounting, the Mounting Spacer ensures that the pulley is correctly aligned with the drive belt. This alignment is essential for the smooth transfer of power and reduces the risk of belt slippage or breakage.

Kit On Board Spares and Overhaul Kits

When utilizing kit on board spares or overhaul kits, the Mounting Spacer is often included to facilitate the replacement or upgrade of existing components. It ensures that new parts are installed with the same precision as the original equipment, maintaining the engine’s performance standards.

Water Pump and Idler Combinations

In configurations where the water pump is combined with an idler, the Mounting Spacer ensures that both components are correctly spaced. This is important for balancing the load on the engine and preventing undue stress on the water pump and idler assembly.

Water Pump Repair Kits

In water pump repair kits, the Mounting Spacer is a key component that aids in the reassembly of the pump. It ensures that all repaired or replaced parts are correctly aligned, which is essential for restoring the pump to its original efficiency.

Water Pump and Manifold Systems

For water pump and manifold systems, the Mounting Spacer helps in achieving the correct alignment between the pump and the manifold. This is crucial for maintaining the flow of coolant and ensuring that the engine remains within optimal operating temperatures.

Conclusion

The 3050395 Mounting Spacer is a fundamental component in various engine systems, providing the necessary alignment and spacing to ensure efficient and reliable operation. Its role in maintaining the structural integrity and operational efficiency of engine components underscores its importance in the maintenance and performance of commercial truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.