This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

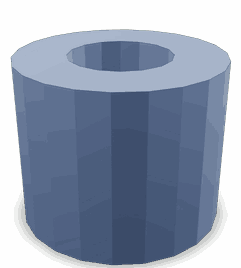

The Cummins 3351763 Mounting Spacer is a component designed for use in commercial truck operations. It serves a specific function within the engine assembly, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Mounting Spacers

Mounting spacers are mechanical components used to create distance between two parts, ensuring proper alignment and stability. They play a role in maintaining the correct spacing, which is vital for the efficient operation of mechanical systems. By providing the necessary gap, mounting spacers help in reducing vibrations, preventing component wear, and ensuring that parts function as intended within the system 1.

Purpose of the 3351763 Mounting Spacer

The 3351763 Mounting Spacer is specifically engineered for use in Cummins engines. It plays a role in the engine’s mounting system by providing the required spacing between the engine and the truck’s frame. This spacing is crucial for maintaining the alignment of the engine components, which in turn contributes to the stability and performance of the engine. Its application is integral to the proper functioning of the engine and associated systems within the truck 2.

Key Features

The 3351763 Mounting Spacer is characterized by its robust material composition, which typically includes high-strength alloys to withstand the rigors of commercial truck operations. Its design specifications are tailored to meet the demanding requirements of heavy-duty applications, ensuring durability and reliability. Unique attributes such as precision machining and surface treatments enhance its performance and longevity, making it a reliable component in the engine assembly 3.

Benefits of Using the 3351763 Mounting Spacer

Incorporating the 3351763 Mounting Spacer into a truck’s engine assembly offers several advantages. It contributes to improved engine performance by ensuring optimal component alignment and reducing vibrations. This alignment is key to the efficient operation of the engine, leading to enhanced overall vehicle performance. Additionally, the spacer’s design helps in prolonging the lifespan of associated parts by minimizing wear and tear, thus offering increased longevity and reliability in commercial truck operations 4.

Installation Process

Installing the 3351763 Mounting Spacer requires careful attention to detail to ensure a secure fit. The process involves positioning the spacer between the engine and the truck’s frame, following the manufacturer’s guidelines for torque specifications and alignment. Utilizing the appropriate tools and equipment is recommended to facilitate a proper installation. Best practices include verifying the spacer’s alignment and securing it in place according to the specified procedures to ensure optimal performance and durability 5.

Troubleshooting Common Issues

Common issues with the 3351763 Mounting Spacer may include misalignment or wear over time. Addressing these problems involves inspecting the spacer for signs of damage or improper installation. Troubleshooting steps may include realigning the spacer, ensuring it is securely fastened, or replacing it if significant wear is detected. Regular inspections and maintenance can help in identifying and resolving issues before they lead to more significant problems 6.

Maintenance Tips

To prolong the lifespan of the 3351763 Mounting Spacer, regular maintenance practices are recommended. This includes periodic inspections for signs of wear or damage, cleaning the spacer to remove any debris that may affect its performance, and following the manufacturer’s guidelines for replacement intervals. Adhering to these maintenance tips can help in ensuring the spacer continues to function effectively, contributing to the overall reliability of the truck’s engine system 7.

Compatibility and Application

The 3351763 Mounting Spacer is designed for use in specific models and makes of trucks and engines, demonstrating its versatility and widespread application in the industry. Its compatibility with various Cummins engines highlights its importance in maintaining the performance and reliability of commercial trucks 8.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck and engine industry, known for its extensive product range and reputation for quality and innovation. With a history of providing reliable and efficient engine solutions, Cummins continues to be a trusted name in the industry, offering components like the 3351763 Mounting Spacer that contribute to the performance and longevity of commercial vehicles 9.

Role of Part 3351763 Mounting Spacer in Engine Systems

The part 3351763 Mounting Spacer is an essential component that facilitates the proper alignment and secure fitting of various engine components. It ensures that parts are correctly spaced and mounted, which is vital for the efficient operation of the engine system.

Integration with Engine Components

-

Air Cleaner and Air Mounting Cleaner: The Mounting Spacer assists in the precise positioning of the air cleaner and air mounting cleaner. This ensures that the air intake system is correctly aligned, allowing for optimal airflow into the engine. Proper airflow is necessary for efficient combustion and overall engine performance 10.

-

Harness and Electronic Control Module (ECM) Wiring: When installing the harness and ECM wiring, the Mounting Spacer helps maintain the correct distance between these components and other parts of the engine. This is important for preventing electrical interference and ensuring that the wiring remains undamaged during engine operation 11.

-

Primer: In systems where a primer is used, the Mounting Spacer ensures that the primer is securely and correctly positioned. This is important for consistent and reliable priming of the engine, which is essential for smooth starting and operation 12.

-

Engine Lubricating System: The Mounting Spacer plays a role in the installation of components within the engine lubricating system. By ensuring that parts such as oil pumps and filters are correctly spaced, it helps maintain the integrity of the lubrication system, which is vital for reducing friction and wear within the engine 13.

-

Regulator Voltage and Voltage Regulator: For components like the regulator voltage and voltage regulator, the Mounting Spacer ensures that these are installed at the correct distance from other electrical components. This helps in maintaining stable voltage levels, which is crucial for the proper functioning of the engine’s electrical systems 14.

Conclusion

In summary, the 3351763 Mounting Spacer is a key component in ensuring that various engine parts are correctly aligned and securely mounted. This contributes to the overall efficiency and reliability of the engine system.

-

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Happian-Smith, J. (2002). An Introduction to Modern Vehicle Design. Butterworth-Heinemann.

↩ -

Cummins Inc. (n.d.). QSV81 and QSV91 CM700 Generator Set, Bulletin Number 4021313, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). QSV81 and QSV91 CM700 Generator Set, Bulletin Number 4021313, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). QSV81 and QSV91 CM700 Generator Set, Bulletin Number 4021313, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). QSV81 and QSV91 CM700 Generator Set, Bulletin Number 4021313, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). QSV81 and QSV91 CM700 Generator Set, Bulletin Number 4021313, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). QSV81 and QSV91 CM700 Generator Set, Bulletin Number 4021313, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). QSV81 and QSV91 CM700 Generator Set, Bulletin Number 4021313, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). QSV81 and QSV91 CM700 Generator Set, Bulletin Number 4021313, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). QSV81 and QSV91 CM700 Generator Set, Bulletin Number 4021313, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). QSV81 and QSV91 CM700 Generator Set, Bulletin Number 4021313, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). QSV81 and QSV91 CM700 Generator Set, Bulletin Number 4021313, Operation and Maintenance Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.