This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

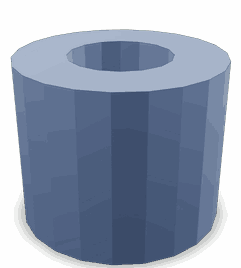

The Cummins 3351875 Mounting Spacer is a component designed for use in heavy-duty truck applications. It serves a specific function within the mechanical assembly of these vehicles, contributing to the overall performance and reliability of the truck. Understanding its purpose and role is fundamental for maintaining and optimizing heavy-duty truck operations.

Basic Concepts of Mounting Spacers

Mounting spacers are mechanical components used to create and maintain precise distances between parts in an assembly. They play a role in ensuring the stability and alignment of components by providing the necessary spacing. This is crucial for the proper functioning of mechanical systems, as it helps prevent undue stress on parts and ensures that components operate within their designed parameters 1.

Purpose of the 3351875 Mounting Spacer

The Cummins 3351875 Mounting Spacer is specifically engineered to maintain proper spacing and alignment between components in heavy-duty truck applications. Its role is to ensure that parts are correctly positioned relative to each other, which is vital for the efficient operation of the truck’s mechanical systems. By maintaining the correct spacing, it helps in reducing wear and tear on components and contributes to the overall performance and longevity of the truck 2.

Key Features

The Cummins 3351875 Mounting Spacer is characterized by several key features that enhance its performance and durability. These include its material composition, which is selected for its strength and resistance to wear, and its precise dimensions, which ensure it fits correctly within the assembly. The design of the spacer is also tailored to withstand the rigors of heavy-duty truck operations, providing reliable performance over time.

Benefits of Using the 3351875 Mounting Spacer

Incorporating the Cummins 3351875 Mounting Spacer into heavy-duty truck assemblies offers several advantages. It contributes to improved component alignment, which can lead to reduced wear and tear on parts. This, in turn, can enhance the overall performance and efficiency of the truck. Additionally, by maintaining proper spacing, the spacer helps in preventing potential issues that could arise from misalignment, thereby supporting the longevity and reliability of the vehicle 3.

Installation Guidelines

Proper installation of the Cummins 3351875 Mounting Spacer is important for ensuring its effectiveness. It should be installed according to the manufacturer’s guidelines, which typically involve positioning it between the components it is designed to space. Care should be taken to ensure it is correctly aligned and securely in place. Following best practices during installation can help avoid common pitfalls, such as misalignment or improper spacing, which could affect the performance of the assembly.

Troubleshooting Common Issues

Common issues associated with mounting spacers, such as misalignment or excessive wear, can often be traced back to installation errors or environmental factors. Troubleshooting these problems involves a systematic approach to identifying the root cause. This may include re-evaluating the installation process, checking for signs of wear or damage, and ensuring that the spacer is compatible with the components it is used with. Addressing these issues promptly can help maintain the performance and reliability of the truck.

Maintenance Tips

Regular maintenance of the Cummins 3351875 Mounting Spacer is important for ensuring its continued performance. This includes periodic inspections to check for signs of wear or damage, cleaning to remove any debris that may have accumulated, and replacing the spacer if it shows signs of significant wear. Adhering to recommended maintenance schedules can help prevent unexpected failures and support the longevity of the truck’s mechanical systems.

Compatibility and Application

The Cummins 3351875 Mounting Spacer is designed for use in specific applications within Cummins engines and other heavy-duty truck components. It is commonly used in models or series where precise spacing and alignment are critical for performance and reliability. Understanding its compatibility and application is important for ensuring it is used correctly and effectively within the intended mechanical assemblies.

Manufacturer Information - Cummins

Cummins Inc. is a leading manufacturer in the heavy-duty truck industry, known for its wide range of products and its reputation for quality and reliability. With a history of innovation and excellence, Cummins provides components and systems that are designed to meet the demanding requirements of heavy-duty applications. The company’s commitment to quality and performance is reflected in its products, including the Cummins 3351875 Mounting Spacer.

Cummins Mounting Spacer 3351875 Compatibility

The Cummins Mounting Spacer part number 3351875 is designed to fit seamlessly with a variety of Cummins engines, ensuring proper alignment and stability during operation. This part is crucial for maintaining the integrity of the engine mounting system, contributing to the overall performance and longevity of the engine.

Engine Compatibility

-

4B3.9 Engines: The 3351875 Mounting Spacer is specifically engineered to fit the 4B3.9 engines. It ensures that the engine is securely mounted to the vehicle’s chassis, reducing vibrations and enhancing operational efficiency.

-

6C8.3 Engines: Similarly, the 3351875 Mounting Spacer is compatible with the 6C8.3 engines. This part is essential for maintaining the precise positioning of the engine, which is critical for optimal performance and minimizing wear and tear on engine components.

Importance of Proper Mounting

Proper engine mounting is vital for several reasons:

-

Vibration Reduction: By ensuring the engine is correctly aligned, the mounting spacer helps to reduce vibrations, which can otherwise lead to mechanical failures and decreased engine lifespan.

-

Performance Optimization: Correct mounting allows the engine to operate at its peak performance, ensuring that all components function as intended without undue stress.

-

Safety: A well-mounted engine contributes to the overall safety of the vehicle by preventing unexpected movements that could lead to accidents.

Installation Considerations

When installing the Cummins Mounting Spacer 3351875, it is important to follow the manufacturer’s guidelines to ensure a proper fit and function. This includes:

-

Correct Torque Specifications: Adhering to the specified torque values during installation is crucial to avoid over-tightening or under-tightening, which can compromise the mounting integrity.

-

Quality of Materials: Using genuine Cummins parts ensures compatibility and reliability, avoiding potential issues that may arise from using substandard components.

-

Regular Inspections: Periodic inspections of the mounting spacer and surrounding components can help identify any wear or damage early, allowing for timely maintenance and preventing potential failures.

Role of Part 3351875 Mounting Spacer in Engine Systems

The Part 3351875 Mounting Spacer is integral to the proper assembly and operation of various engine components. It ensures precise alignment and spacing between parts, which is essential for the efficient functioning of the engine system.

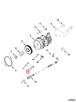

Air Compressor

In the air compressor system, the Mounting Spacer is used to maintain the correct distance between the compressor and its mounting points. This ensures that the compressor operates within its designed parameters, allowing for optimal air compression and delivery. Proper spacing prevents undue stress on the compressor, enhancing its longevity and performance.

Breather Assembly Tube

For the breather assembly tube, the Mounting Spacer plays a role in securing the tube in place while allowing for necessary expansion and contraction due to thermal changes. This ensures that the breather system functions correctly, managing crankcase ventilation and preventing the buildup of pressure that could lead to oil leaks or engine damage.

Crankcase Breather

In the crankcase breather system, the Mounting Spacer helps in aligning the breather with the crankcase. This alignment is vital for effective ventilation, which is necessary to expel contaminants and moisture from the crankcase. Proper ventilation contributes to maintaining clean oil and reducing the risk of sludge formation.

Crankcase Breather Arrangement

Within the crankcase breather arrangement, the Mounting Spacer ensures that all components are correctly positioned relative to each other. This arrangement is designed to facilitate the smooth flow of gases from the crankcase to the intake system, thereby improving engine efficiency and reducing emissions.

Mounting Compressor Air

When mounting the compressor air system, the Mounting Spacer ensures that the compressor is securely fastened without compromising its operational integrity. This is important for maintaining the correct air pressure and flow required for various engine functions, such as fuel injection and pneumatic controls.

Vacuum Pump

In vacuum pump applications, the Mounting Spacer is used to secure the pump in the correct position. This is essential for generating the required vacuum levels for functions such as brake booster operation and emission control systems. Proper mounting ensures that the vacuum pump operates efficiently and reliably.

Conclusion

The Cummins 3351875 Mounting Spacer plays a critical role in the mechanical assembly of heavy-duty trucks, ensuring precise alignment and spacing between components. Its proper installation, maintenance, and understanding of its compatibility and application are essential for optimizing the performance, reliability, and longevity of the vehicle. By adhering to manufacturer guidelines and best practices, operators can ensure the efficient and safe operation of their trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.