This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

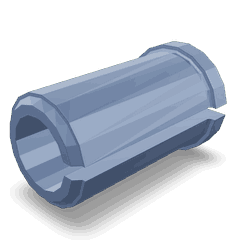

The Cummins 3679266 Mounting Spacer is a component designed for use in commercial truck operations. Its primary role is to ensure proper alignment and spacing between various engine components, contributing to the overall efficiency and reliability of the truck’s engine system 1.

Purpose and Function

The mounting spacer serves a vital function by facilitating the correct alignment and spacing between engine components. This ensures that parts fit together seamlessly, reducing the risk of mechanical issues that can arise from improper alignment. By maintaining the precise distance between components, the mounting spacer helps in the smooth operation of the engine, enhancing its performance and longevity 2.

Key Features

The Cummins 3679266 Mounting Spacer is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring it can withstand the rigors of commercial truck operations. The spacer is designed with specific dimensions to fit precisely within the engine assembly, and its design characteristics are tailored to provide optimal support and alignment for the components it separates 3.

Benefits

Utilizing the Cummins 3679266 Mounting Spacer offers several advantages. It improves component alignment, which is crucial for the efficient operation of the engine. By ensuring parts are correctly spaced, it reduces wear and tear on the engine components, leading to enhanced overall truck performance. Additionally, proper alignment can contribute to fuel efficiency and reduced maintenance costs over time 4.

Installation Process

Installing the Cummins 3679266 Mounting Spacer requires careful attention to detail to ensure correct fitting. The process involves positioning the spacer between the designated engine components, using the appropriate tools to secure it in place. It is important to follow best practices during installation to avoid any misalignment, which could lead to mechanical issues. Detailed instructions and any required tools should be referenced to ensure a successful installation 5.

Common Issues and Troubleshooting

Mounting spacers, like any mechanical component, can encounter issues such as misalignment or wear over time. Common problems may include difficulty in fitting the spacer correctly or signs of wear that affect its performance. Troubleshooting these issues involves inspecting the spacer and surrounding components for any signs of damage or incorrect installation. Addressing these problems promptly can prevent more significant mechanical issues down the line 6.

Maintenance Tips

Regular maintenance is key to prolonging the lifespan of the Cummins 3679266 Mounting Spacer. This includes periodic inspections to check for any signs of wear or damage. Maintenance practices should also involve cleaning the spacer and ensuring it remains in good condition. Being aware of the signs of potential failure can help in taking preemptive action to replace or repair the spacer before it leads to engine problems 7.

Manufacturer Information

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its commitment to producing high-quality components. With a rich history and a strong reputation, Cummins has established itself as a leader in the field, providing reliable and durable parts for a wide range of applications, including commercial trucks. Their dedication to quality and innovation ensures that components like the Cummins 3679266 Mounting Spacer meet the high standards required for demanding commercial use 8.

Role of Part 3679266 Mounting Spacer in Engine Systems

The Cummins 3679266 Mounting Spacer is integral to the proper functioning and alignment of several key components within engine systems.

In the context of alternator mounting, the Mounting Spacer ensures that the alternator is positioned correctly relative to the engine block. This precise alignment is essential for the efficient transfer of mechanical energy from the engine to the alternator, which in turn generates electrical power for the vehicle’s electrical systems.

For the refrigerant compressor, the Mounting Spacer plays a significant role in maintaining the correct spacing between the compressor and other engine components. This is particularly important for the refrigerant compressor mounting system, where the spacer helps in achieving the optimal operational clearance. Proper spacing ensures that the compressor operates within its designed parameters, enhancing the efficiency and reliability of the vehicle’s air conditioning system.

Additionally, in the refrigerant compressor support structure, the Mounting Spacer contributes to the overall stability and vibration damping of the compressor. By providing a consistent and reliable mounting point, the spacer helps in reducing unwanted vibrations that could otherwise lead to premature wear or failure of the compressor and its associated components.

Overall, the Cummins 3679266 Mounting Spacer is a fundamental component that ensures the accurate installation and reliable operation of these critical engine system elements 9.

Conclusion

The Cummins 3679266 Mounting Spacer plays a crucial role in maintaining the alignment and spacing of engine components, ensuring the efficient and reliable operation of commercial truck engines. Its high-quality construction, precise design, and ease of installation make it a valuable component in the maintenance and performance of these vehicles.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Sander, F. (2007). Diesel Mechanics, First Edition. Global Media.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Cummins Inc. (n.d.). Fluids for Cummins® Products, Service Manual (5411406).

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Sander, F. (2007). Diesel Mechanics, First Edition. Global Media.

↩ -

Cummins Inc. (n.d.). Fluids for Cummins® Products, Service Manual (5411406).

↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.