This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3818125 Mounting Spacer is a component designed for use in commercial truck operations. Its primary role is to ensure proper alignment and spacing between various components within the truck’s assembly. This part is integral to maintaining the structural integrity and operational efficiency of the vehicle 1.

Purpose and Function

The mounting spacer serves a specific purpose in truck assembly by facilitating the correct alignment and spacing between components. It ensures that parts are positioned accurately relative to each other, which is vital for the smooth operation of the truck. Proper alignment reduces the risk of mechanical issues and enhances the overall performance of the vehicle 2.

Key Features

The Cummins 3818125 Mounting Spacer is characterized by several key features that contribute to its performance and durability. It is composed of high-quality materials that are resistant to wear and corrosion. The dimensions of the spacer are precisely engineered to fit specific applications, ensuring a snug and secure fit. Its design includes features that enhance stability and reduce the likelihood of component misalignment 3.

Benefits

The use of the Cummins 3818125 Mounting Spacer offers several benefits. It improves component alignment, which is crucial for the efficient operation of the truck. By maintaining proper spacing, it helps reduce vibration, which can lead to component wear and failure. Additionally, the spacer enhances the stability of the assembly, contributing to a longer equipment lifespan. These factors combined result in improved reliability and performance of the truck 1.

Installation Guidelines

Proper installation of the Cummins 3818125 Mounting Spacer is important for its effective function. The process involves several steps, including the use of recommended tools and adherence to torque specifications. Safety precautions should be observed throughout the installation to prevent injury and ensure the integrity of the component. Detailed instructions should be followed to achieve the best results 2.

Maintenance Tips

To ensure the optimal performance of the mounting spacer, regular maintenance is recommended. This includes inspecting the spacer for signs of wear or damage, cleaning it according to manufacturer guidelines, and replacing it at recommended intervals. Proper maintenance helps to prolong the life of the spacer and maintain the efficiency of the truck 3.

Troubleshooting Common Issues

Common issues associated with mounting spacers may include misalignment, excessive vibration, or component failure. Troubleshooting these problems involves a systematic approach to identify the root cause. Potential solutions may range from realigning components to replacing worn-out parts. Addressing these issues promptly can prevent further damage and ensure the continued reliability of the truck 1.

Manufacturer Information

Cummins Inc. is a well-established manufacturer with a strong reputation in the automotive industry. The company is known for its commitment to quality and innovation in the production of automotive components. Cummins Inc. has a history of delivering reliable and high-performance parts that meet the demanding requirements of commercial truck operations 2.

Cummins Engine Compatibility with Mounting Spacer Part 3818125

The Cummins Mounting Spacer part number 3818125 is a versatile component designed to fit a variety of Cummins engines. This part is essential for ensuring proper alignment and stability of the engine within its mounting system. Below is a detailed overview of the engines with which this mounting spacer is compatible.

Compatible Engines

- ISC8.3 CM2250

- ISL9 CM2150 SN

- ISL9 CM2250

- ISM CM570

- ISM11 CM876 SN

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

- QSM11 CM570

- VTA903 CM2250 V105

Grouping by Engine Series

I-Series Engines

The I-Series engines, including the ISC8.3 CM2250, ISL9 CM2150 SN, ISL9 CM2250, and ISM CM570, are designed for heavy-duty applications. The mounting spacer 3818125 ensures that these engines maintain their structural integrity and operational efficiency by providing a stable connection between the engine and its mounting points.

ISM and ISM11 Engines

The ISM CM570 and ISM11 CM876 SN engines are part of the ISM series, which is known for its reliability and performance in various industrial applications. The mounting spacer 3818125 is engineered to fit these engines, ensuring that they are securely mounted and aligned.

L-Series Engines

The L-Series engines, including the L10 CELECT, L10 GAS, and L10 MECHANICAL, are designed for a range of applications from marine to industrial use. The mounting spacer 3818125 is compatible with these engines, providing the necessary support and stability for their operation.

M-Series Engines

The M-Series engines, such as the M11 CELECT, M11 CELECT PLUS, and M11 MECHANICAL, are known for their power and efficiency. The mounting spacer 3818125 is designed to fit these engines, ensuring that they are properly aligned and supported within their mounting systems.

QSM11 Engine

The QSM11 CM570 engine is part of the QSM series, which is designed for high-performance applications. The mounting spacer 3818125 is compatible with this engine, providing the necessary support and stability for its operation.

VTA903 Engine

The VTA903 CM2250 V105 engine is a specialized model designed for specific applications. The mounting spacer 3818125 is engineered to fit this engine, ensuring that it is securely mounted and aligned.

This comprehensive compatibility ensures that the mounting spacer 3818125 can be used across a wide range of Cummins engines, providing a reliable and efficient solution for engine mounting needs 3.

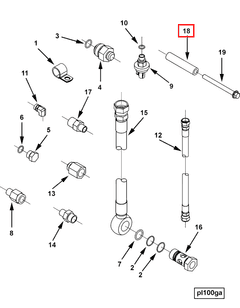

Role of Part 3818125 Mounting Spacer in Engine Systems

The Part 3818125 Mounting Spacer is an essential component in the precise arrangement and functionality of various engine systems. It ensures proper spacing and alignment between components, which is vital for the efficient operation of the engine 1.

Turbocharger Arrangement

In turbocharger setups, the Mounting Spacer is used to maintain the correct distance between the turbocharger and the engine block. This spacing is important for the proper alignment of the turbocharger’s inlet and outlet, ensuring smooth airflow and efficient turbo operation 2.

Engine Oil Primer Plumbing

When integrating the engine oil primer into the plumbing system, the Mounting Spacer helps in achieving the right distance between the primer and other components. This ensures that the oil flow is unimpeded and that the primer functions correctly to lubricate the engine effectively 3.

Exhaust Manifold Kit

In the exhaust manifold kit, the Mounting Spacer is utilized to secure the manifold to the engine block while providing the necessary gap for thermal expansion and contraction. This prevents stress on the manifold and ensures a leak-free seal 1.

Fuel Filter Location

At the fuel filter location, the Mounting Spacer ensures that the filter is positioned correctly within the fuel system. Proper spacing is essential to avoid any obstruction in the fuel flow and to maintain the filter’s efficiency in cleaning the fuel before it reaches the engine 2.

Heat Shield

The Mounting Spacer is also employed in the installation of heat shields. It ensures that the shield is held at a safe distance from heat-generating components, such as the exhaust manifold, to prevent heat transfer and protect surrounding parts 3.

Fuel Filter and Mounting

When mounting the fuel filter, the spacer is critical in maintaining the correct distance from the engine and other components. This ensures that the filter operates within its designed parameters and provides optimal filtration 1.

Exhaust Manifold

In the context of the exhaust manifold, the Mounting Spacer ensures that the manifold is securely fastened to the engine while allowing for the necessary thermal movement. This is key to preventing cracks and ensuring a durable exhaust system 2.

Plumbing and Oil Cooler Water

For the plumbing of the oil cooler water system, the Mounting Spacer is used to keep the correct spacing between the cooler and the engine. This is important for the efficient transfer of heat and the overall cooling performance of the engine 3.

Turbocharger Location

At the turbocharger location, the Mounting Spacer ensures that the turbocharger is installed at the optimal distance from the engine and other components. This is essential for the turbocharger’s performance and the engine’s overall efficiency 1.

Conclusion

The Cummins 3818125 Mounting Spacer plays a crucial role in the alignment and spacing of components within commercial truck assemblies. Its high-quality materials, precise engineering, and compatibility with a wide range of Cummins engines make it a reliable and efficient component for maintaining the structural integrity and operational efficiency of the vehicle. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this Cummins part, ensuring the continued reliability and performance of the truck 123.

-

Vehicle Dynamics and Control, Rajesh Rajamani, Springer, 2005

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ -

Diesel Emissions and Their Control: Second Edition, Addy Majewski and Hannu Jaskelainen, SAE International, 2023

↩ ↩ ↩ ↩ ↩ ↩ ↩ -

Controlling Noise and Vibration in Road Vehicles, Matthew Harrison, SAE International, 2004

↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.