This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4094052 Mounting Spacer is a component designed to facilitate the proper installation and alignment of various parts within commercial trucks. Its role is integral to ensuring that the mechanical assemblies within these vehicles operate efficiently and reliably. By providing the necessary spacing and alignment, this mounting spacer contributes to the overall performance and longevity of the truck’s engine and transmission systems 1.

Basic Concepts of Mounting Spacers

Mounting spacers are mechanical components used to create the required distance between two parts in an assembly. They play a role in maintaining the correct alignment and stability of components, which is vital for the efficient operation of machinery. In the context of commercial trucks, mounting spacers ensure that engines and transmissions are properly positioned, which helps in reducing wear and tear, minimizing vibrations, and enhancing the overall performance of the vehicle 2.

Purpose of the Cummins 4094052 Mounting Spacer

The Cummins 4094052 Mounting Spacer is specifically designed for use in truck engine or transmission mounting systems. It plays a role in ensuring that these critical components are correctly aligned and spaced. This alignment is important for the efficient transfer of power and the reduction of stress on mounting points, which can lead to improved performance and durability of the truck’s powertrain 3.

Key Features

The Cummins 4094052 Mounting Spacer is characterized by its robust material composition, precise dimensions, and design features that enhance its performance and durability. Made from high-quality materials, it is engineered to withstand the rigors of commercial truck operations. Its dimensions are carefully calculated to provide the exact spacing required for optimal component alignment, and its design includes features that facilitate easy installation and reliable operation 4.

Benefits of Using the Cummins 4094052 Mounting Spacer

Utilizing the Cummins 4094052 Mounting Spacer offers several advantages. It contributes to improved alignment of engine and transmission components, which can lead to reduced vibration during operation. This, in turn, may enhance the durability of the components and potentially increase their lifespan. Additionally, the proper spacing provided by the mounting spacer can help in maintaining the efficiency of the truck’s powertrain, leading to better overall performance 5.

Installation Considerations

When installing the Cummins 4094052 Mounting Spacer, it is important to follow guidelines and best practices to ensure proper fitting. This includes using the necessary tools, preparing the installation area, and performing alignment checks to confirm that the spacer is correctly positioned. Attention to these details can help in achieving the desired performance and longevity of the truck’s engine and transmission systems 6.

Troubleshooting Common Issues

Common problems associated with mounting spacers, such as misalignment or wear, can affect the performance of the truck’s engine and transmission. Identifying these issues early and taking appropriate troubleshooting steps can help in maintaining the efficiency and reliability of the vehicle. Regular inspections and timely replacements, when necessary, are recommended to address these concerns effectively 7.

Maintenance Tips

Regular maintenance of the Cummins 4094052 Mounting Spacer is important for ensuring its continued performance and durability. This includes periodic inspections to check for signs of wear or damage, cleaning the spacer to remove any debris that may affect its operation, and considering replacement if significant wear is observed. Adhering to these maintenance practices can contribute to the longevity and efficiency of the truck’s powertrain 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The Cummins 4094052 Mounting Spacer, as part of their product range, reflects the company’s dedication to providing reliable and high-performance components for the commercial vehicle market 9.

Compatible Engines

The Cummins Mounting Spacer part number 4094052 is designed to fit a variety of Cummins engines, ensuring proper alignment and stability during operation. This part is integral to the mounting system of several Cummins engine models.

- 4B3.9

- 6B5.9

- B5.6 CM2670 B152B

- B5.9 GAS PLUS CM556

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B140

- ISB5.9 CM2880 B149

- ISB5.9G CM2180

- QSB5.9 CM2880 B115

Role of Part 4094052 Mounting Spacer in Engine Systems

The Part 4094052 Mounting Spacer is integral to the assembly and operation of various engine components. It ensures proper alignment and spacing between parts, which is essential for the efficient functioning of the engine system 10.

Accessories and Wiring

In the integration of accessories and wiring within the engine bay, the Mounting Spacer provides the necessary distance between components to prevent interference. This spacing is vital for the safe routing of wiring harnesses and the mounting of accessories such as sensors and solenoids 11.

Breather and Crankcase

For the breather system connected to the crankcase, the Mounting Spacer allows for the correct installation of the breather hoses and filters. It ensures that there is adequate clearance for the breather to function without obstruction, which is important for maintaining crankcase pressure and oil contamination levels 12.

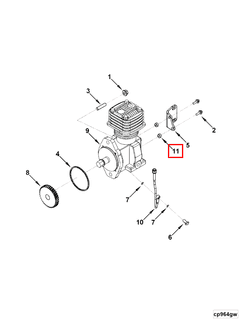

Compressor and Air Coupling

When installing the compressor within the engine system, the Mounting Spacer is used to secure the air coupling. This ensures that the compressor is aligned correctly with the air intake system, allowing for optimal airflow and performance 13.

Fuel Pump and Cover

The Mounting Spacer is also employed in the assembly of the fuel pump and its cover. It provides the required separation to allow for the fuel pump’s movement and operation without contacting the engine block or other components, which could lead to damage or reduced efficiency 14.

Front Gear and Fuel Pump Coupling

In the context of the front gear and fuel pump coupling, the Mounting Spacer ensures that these components are installed at the correct distance from each other. This is important for the smooth operation of the fuel delivery system and to prevent mechanical wear or failure 15.

Module and Engine Control

For engine control modules that require precise mounting, the Mounting Spacer ensures that the module is installed at the correct height and angle. This is essential for the module’s sensors to accurately read engine parameters and for the module to communicate effectively with other engine components 16.

Plumbing and Fuel

In the plumbing of fuel lines, the Mounting Spacer is used to maintain the correct distance between the fuel lines and other engine components. This prevents potential fuel leaks and ensures that the fuel lines are not subjected to undue stress or heat, which could compromise their integrity 17.

Turbocharger Coolant

Finally, in turbocharger systems that require coolant lines, the Mounting Spacer is utilized to ensure that the coolant lines are installed with the proper clearance. This is important for the efficient cooling of the turbocharger and to prevent any potential leaks or damage to the coolant system 18.

Conclusion

The Cummins 4094052 Mounting Spacer plays a crucial role in the proper installation and alignment of engine and transmission components in commercial trucks. Its robust design, precise dimensions, and compatibility with a range of Cummins engines make it an essential component for maintaining the efficiency, reliability, and longevity of the truck’s powertrain. Regular maintenance and proper installation practices are key to maximizing the benefits of this Cummins part.

-

Lejda, K., & Wos, P. (2012). Internal Combustion Engines. InTech.

↩ -

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Lejda, K., & Wos, P. (2012). Internal Combustion Engines. InTech.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩ -

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins official website.

↩ -

Lejda, K., & Wos, P. (2012). Internal Combustion Engines. InTech.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩ -

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Lejda, K., & Wos, P. (2012). Internal Combustion Engines. InTech.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩ -

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Lejda, K., & Wos, P. (2012). Internal Combustion Engines. InTech.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.