4311968

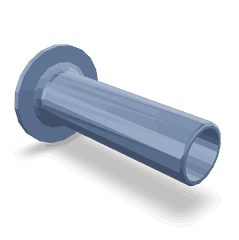

Mounting Spacer

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4311968 Mounting Spacer is a critical component in heavy-duty truck systems, designed to ensure proper spacing and alignment between various mechanical components. This contributes to the overall stability and efficiency of the truck’s operation. Understanding the role and significance of this mounting spacer is essential for maintaining the performance and longevity of heavy-duty trucks.

Basic Concepts of Mounting Spacers

Mounting spacers are mechanical components used to create and maintain specific distances between parts within a system. They ensure that components are correctly aligned and spaced, which is vital for the stability and functionality of mechanical systems 1. By providing the necessary separation, mounting spacers help prevent components from coming into direct contact, which could lead to wear, misalignment, or failure.

Purpose of the 4311968 Mounting Spacer

The 4311968 Mounting Spacer is specifically designed to maintain proper spacing and alignment between components in a truck’s mechanical system. It ensures that parts are positioned correctly relative to each other, which is crucial for the efficient operation of the truck. This spacer helps in distributing loads evenly and reducing the risk of component wear or damage due to improper alignment.

Key Features

The 4311968 Mounting Spacer is characterized by several key features that enhance its performance and durability. It is made from high-quality materials that can withstand the rigors of heavy-duty truck applications. The spacer has precise dimensions to ensure accurate spacing and alignment. Its design includes features that facilitate easy installation and removal, contributing to its overall effectiveness in truck maintenance and repair.

Benefits of Using the 4311968 Mounting Spacer

Using the 4311968 Mounting Spacer offers several advantages. It improves the alignment of components, which can lead to reduced wear and tear on mechanical parts. This, in turn, enhances the overall performance and reliability of the truck. Additionally, proper spacing provided by the spacer helps in maintaining the intended clearances between components, which is crucial for the smooth operation of the truck’s mechanical systems.

Installation Process

Installing the 4311968 Mounting Spacer involves several steps to ensure correct placement and function. First, the area where the spacer will be installed should be cleaned to remove any debris or old spacer material. The spacer is then positioned between the components it is designed to separate. Tools such as wrenches or sockets may be required to secure the spacer in place. It is important to follow the manufacturer’s guidelines for torque specifications to ensure the spacer is properly installed without over-tightening.

Troubleshooting Common Issues

Common issues with mounting spacers can include misalignment or wear. If components appear misaligned after installation, it may be necessary to re-evaluate the placement of the spacer or check for any obstructions that could be affecting its position. Wear on the spacer itself may indicate that it needs to be replaced. Regular inspections can help identify these issues early, allowing for timely corrections.

Maintenance Tips

Regular maintenance of the 4311968 Mounting Spacer is important to ensure its continued effectiveness. This includes periodic inspections to check for signs of wear or damage. Cleaning the spacer and its surrounding area can help prevent the buildup of debris that could affect its performance. If significant wear is observed, or if the spacer shows signs of damage, it should be replaced to maintain the proper spacing and alignment of components.

Compatibility and Application

The 4311968 Mounting Spacer is designed for use in specific heavy-duty truck models and systems. It is important to verify compatibility with the truck’s make and model to ensure proper fit and function. This spacer is commonly used in applications where precise component alignment and spacing are required for optimal performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the automotive and heavy-duty truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of vehicles and equipment 2.

Mounting Spacer 4311968 Compatibility with Cummins Engines

The Cummins Mounting Spacer part number 4311968 is designed to fit seamlessly with a range of Cummins engines, ensuring proper alignment and stability during operation. This part is crucial for maintaining the integrity of the engine mounting system, providing a secure interface between the engine and its mounting points.

ISX CM570

The ISX CM570 engine, known for its robust performance and reliability, is one of the engines that can utilize the 4311968 Mounting Spacer. This spacer ensures that the engine is securely fastened to its mounting points, reducing vibrations and enhancing overall engine stability.

Other Cummins Engines

In addition to the ISX CM570, the 4311968 Mounting Spacer is compatible with various other Cummins engines. This versatility makes it a valuable component for maintaining the structural integrity of different engine models within the Cummins lineup. The spacer’s design allows it to fit snugly and securely, providing a reliable connection that is essential for the engine’s optimal performance.

Role of Part 4311968 Mounting Spacer in Engine Systems

The part 4311968 Mounting Spacer is a critical component in ensuring the proper alignment and spacing between various engine components. Its primary function is to maintain the correct distance and positioning, which is vital for the efficient operation of the engine 3.

Integration with Electronic Control Module (ECM) Kit

When integrating the 4311968 Mounting Spacer with an Electronic Control Module (ECM) Kit, it ensures that the ECM is securely and accurately positioned within the engine bay. This is important for maintaining the integrity of the electrical connections and ensuring that the ECM can effectively communicate with other engine components. Proper spacing provided by the mounting spacer prevents any undue stress on the connections, which could otherwise lead to signal interference or failure.

Application in Module Assemblies

In module assemblies, the 4311968 Mounting Spacer plays a significant role in maintaining the structural integrity of the module. It ensures that all internal components within the module are aligned correctly, which is essential for the module’s functionality. This alignment is particularly important in high-vibration environments, where even minor misalignments can lead to component failure over time.

Engine Control Systems

For Engine Control systems, the 4311968 Mounting Spacer is used to ensure that sensors and actuators are positioned correctly relative to the engine block. This is important for accurate readings and precise control over engine operations. The spacer helps in maintaining the optimal distance between the engine control components and the engine block, ensuring that all measurements and adjustments are within the specified tolerances.

Conclusion

The 4311968 Mounting Spacer is a key component in various engine systems, providing the necessary spacing and alignment to ensure that all components function efficiently and reliably. Its role in maintaining the integrity of engine mounting systems, facilitating proper alignment in module assemblies, and ensuring accurate positioning in engine control systems underscores its importance in the operation and maintenance of heavy-duty trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.