This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

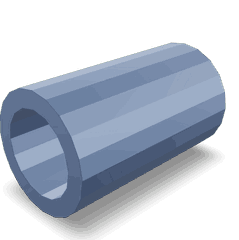

The Cummins 5288612 Mounting Spacer is a component designed for use in heavy-duty truck applications. Its primary role is to ensure proper alignment and spacing between various truck components, contributing to the overall efficiency and reliability of the vehicle 1.

Purpose and Function

The mounting spacer serves a vital function in truck assemblies by facilitating the correct alignment and spacing between components. This ensures that parts fit together precisely, which is crucial for the smooth operation of the truck. By maintaining the appropriate distance between components, the spacer helps to prevent issues such as misalignment, which can lead to increased wear and reduced performance 2.

Key Features

The Cummins 5288612 Mounting Spacer is constructed from high-quality materials, ensuring durability and reliability in demanding truck environments. Its design includes specific dimensions that are tailored to fit precisely within the truck’s assembly, enhancing its performance. The spacer is engineered to withstand the rigors of heavy-duty use, providing long-lasting support for the components it separates 3.

Benefits

Using the Cummins 5288612 Mounting Spacer offers several advantages. It improves component alignment, which can lead to reduced vibration and noise during operation. Additionally, proper spacing between components can enhance the overall efficiency of the truck’s systems, contributing to better performance and longevity of the vehicle 4.

Installation Considerations

When installing the Cummins 5288612 Mounting Spacer, it is important to follow specific guidelines to ensure optimal performance. This includes adhering to torque specifications to secure the spacer in place without over-tightening, which could damage the component or surrounding parts. Proper alignment procedures should be followed to ensure that the spacer is positioned correctly within the assembly 5.

Maintenance and Troubleshooting

To maintain the Cummins 5288612 Mounting Spacer and ensure its optimal performance over time, regular inspections are recommended. This involves checking for signs of wear or damage and ensuring that the spacer remains properly aligned. Common issues that may arise include misalignment or damage from excessive vibration, which can be addressed by realigning the component or replacing it if necessary 6.

Manufacturer Information

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its commitment to producing high-quality components for heavy-duty trucks. With a history of innovation and excellence, Cummins has established a strong reputation for reliability and performance. The company’s dedication to quality is evident in its range of products, including the Cummins 5288612 Mounting Spacer, which is designed to meet the demanding requirements of heavy-duty truck applications 7.

Component Usage

The Cummins 5288612 Mounting Spacer is instrumental in ensuring the proper alignment and spacing between various engine components. When integrated into the alternator mounting system, this spacer facilitates the correct positioning of the alternator relative to the engine block and other adjacent parts.

In the context of alternator mounting, the spacer allows for the precise clearance necessary for the alternator’s pulley to engage with the serpentine belt without interference from surrounding components. This ensures smooth operation and reduces the risk of belt slippage or damage.

Additionally, the Mounting Spacer plays a significant role in maintaining the structural integrity of the mounting system. By providing a consistent gap, it helps distribute loads evenly across the mounting points, which is essential for the longevity and reliability of the alternator and its connections 8.

Conclusion

The Cummins 5288612 Mounting Spacer is a key component in the alternator mounting system, contributing to the efficient and reliable operation of the engine by ensuring proper alignment, clearance, and load distribution.

-

Maclaurin, Bruce. High Speed Off-Road Vehicles. Wiley, 2018.

↩ -

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Drozdziel, Pawel. The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge, 2023.

↩ -

Cummins Inc. Owners Manual for ISB/ISD4.5 CM2150 B119. Bulletin Number 4358466.

↩ -

Cummins Inc. Owners Manual for ISB/ISD4.5 CM2150 B119. Bulletin Number 4358466.

↩ -

Cummins Inc. Owners Manual for ISB/ISD4.5 CM2150 B119. Bulletin Number 4358466.

↩ -

Cummins Inc. Owners Manual for ISB/ISD4.5 CM2150 B119. Bulletin Number 4358466.

↩ -

Cummins Inc. Owners Manual for ISB/ISD4.5 CM2150 B119. Bulletin Number 4358466.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.