This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3420946 Speed Sensor is a component designed to monitor and report the rotational speed of various parts within commercial trucks. Its purpose is to provide accurate speed data that is integral to the operation and management of the vehicle’s systems. This sensor plays a role in ensuring the truck operates efficiently and safely by facilitating precise control over various functions 1.

Basic Concepts of Speed Sensors

A speed sensor is a device that detects the rate of rotation of an object and converts it into an electrical signal. This signal is then used by the vehicle’s electronic control systems to make adjustments and decisions. Speed sensors are commonly used in automotive systems to monitor wheel speed, engine speed, and the speed of other rotating components. They are vital for functions such as anti-lock braking systems (ABS), traction control, and transmission shifting 2.

Role of the 3420946 Speed Sensor in Truck Operation

The Cummins 3420946 Speed Sensor is specifically designed to perform several functions within a truck’s system. It collects data on the rotational speed of components such as wheels or transmission parts. This data is then transmitted to the truck’s electronic control unit (ECU), where it is used to make real-time adjustments to the vehicle’s operation. The sensor integrates with other components to ensure that the truck’s systems operate in harmony, enhancing both performance and safety 3.

Key Features of the 3420946 Speed Sensor

The Cummins 3420946 Speed Sensor is characterized by its robust design and high-quality materials, which contribute to its durability and reliability. The sensor utilizes advanced technology to ensure accurate and consistent speed readings. Its design includes features that protect it from the harsh environments typical of commercial truck operations, such as exposure to dirt, moisture, and temperature fluctuations.

Benefits of Using the 3420946 Speed Sensor

Incorporating the Cummins 3420946 Speed Sensor into a truck’s system offers several advantages. It contributes to improved fuel efficiency by enabling the ECU to make precise adjustments based on speed data. Enhanced safety features are also a benefit, as the sensor provides critical information for systems like ABS and traction control. Additionally, the sensor helps in achieving better overall performance of the truck by ensuring that all systems operate optimally based on accurate speed data.

Installation and Integration

Installing the Cummins 3420946 Speed Sensor involves mounting it in the appropriate location within the truck’s system, typically near the component whose speed it is designed to monitor. Integration with the truck’s existing systems requires connecting the sensor to the ECU and ensuring that it is properly configured to communicate with other components. This process may involve adjustments to the system’s settings to accommodate the new sensor.

Troubleshooting and Maintenance

Common issues with the Cummins 3420946 Speed Sensor may include inaccurate readings or complete failure to operate. Diagnostic procedures involve checking the sensor’s connections, inspecting it for physical damage, and verifying that it is correctly configured within the truck’s system. Maintenance tips for ensuring the sensor’s longevity and optimal performance include regular inspection for signs of wear or damage, cleaning it to remove dirt and debris, and ensuring that all connections are secure and free from corrosion.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a leader in the automotive industry through its commitment to innovation, quality, and customer satisfaction. The company’s product range includes engines, powertrains, and related components for on-highway, off-highway, and stationary applications, demonstrating its versatility and expertise in the field.

Cummins Speed Sensor 3420946 Compatibility

The Cummins Speed Sensor part number 3420946 is designed to fit seamlessly with a variety of engine models. This sensor is integral for maintaining optimal engine performance by accurately measuring the rotational speed of the engine components. Below is a detailed overview of the engines with which this speed sensor is compatible.

Compatible Engines

-

QSV81G and QSV91G The 3420946 speed sensor is engineered to integrate with the QSV81G and QSV91G engines. These engines are known for their robust performance and reliability, making the speed sensor a crucial component for ensuring precise engine operation.

-

QSW/QSV82 This engine model also benefits from the 3420946 speed sensor. The sensor’s compatibility with the QSW/QSV82 engine ensures that the engine’s performance metrics are accurately monitored, contributing to overall engine efficiency and longevity.

-

QSW27 and QSW36 The 3420946 speed sensor is also suitable for the QSW27 and QSW36 engines. These engines are part of a series that demands high precision in speed measurement, and the sensor provides the necessary data for effective engine management.

-

QSW73 Lastly, the QSW73 engine is another model that is compatible with the 3420946 speed sensor. This compatibility ensures that the engine can operate at peak efficiency, with the sensor providing real-time data to the engine control unit.

Grouping of Compatible Engines

The engines listed above can be grouped based on their series and performance characteristics. The QSV81G and QSV91G engines, along with the QSW/QSV82, are part of a series known for their high power output and reliability. The QSW27 and QSW36 engines, while slightly different in design, share a similar requirement for precise speed measurement. The QSW73 engine, while distinct, also benefits from the same level of accuracy provided by the 3420946 speed sensor.

By ensuring that the 3420946 speed sensor is compatible with these engines, Cummins maintains a high standard of performance and reliability across its engine lineup. This compatibility is crucial for technicians and operators who rely on accurate engine data for maintenance and operational efficiency.

Role of Part 3420946 Speed Sensor in Engine Systems

The Part 3420946 Speed Sensor is integral to the operation of various engine systems, ensuring precise and efficient performance. Here’s how it interfaces with key components:

Electric Assembly Governor

The Speed Sensor provides real-time rotational speed data to the Electric Assembly Governor. This data allows the governor to make necessary adjustments to maintain optimal engine speed, enhancing overall performance and fuel efficiency.

Electric Governor

In systems utilizing an Electric Governor, the Speed Sensor feeds critical speed information that the governor uses to modulate fuel delivery and ignition timing. This ensures the engine operates within specified parameters, reducing wear and improving reliability.

Electronic Control Engine

When integrated with an Electronic Control Engine, the Speed Sensor’s data is vital for the engine’s electronic control unit (ECU) to execute precise control over various engine functions. This includes fuel injection timing, valve timing, and turbo boost pressure, leading to better performance and emissions control.

Engine Control Module (ECM)

The ECM relies on the Speed Sensor to monitor engine RPM. This information is used to adjust the air-fuel mixture, ignition timing, and other parameters to ensure the engine runs smoothly under varying loads and conditions.

Engine Electronic Control

In engines with advanced electronic control systems, the Speed Sensor’s input is essential for fine-tuning engine operations. It allows the system to respond quickly to changes in load or speed, maintaining efficiency and performance.

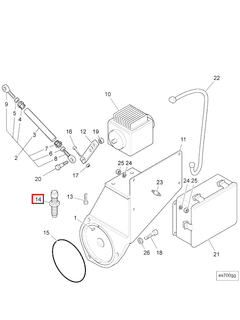

Flywheel Assembly Housing

The Speed Sensor often mounts to the Flywheel Assembly Housing to directly measure the rotational speed of the flywheel. This direct measurement ensures accurate data for the governor and ECM, facilitating precise control over engine speed and performance.

Fuel Assembly Control

The Speed Sensor’s data is used by the Fuel Assembly Control to adjust the fuel delivery rate in response to engine speed. This ensures the engine receives the correct amount of fuel at any given RPM, optimizing combustion and efficiency.

Governor (Electronic)

In electronic governor systems, the Speed Sensor provides continuous speed feedback. This allows the governor to make dynamic adjustments to the engine’s operation, ensuring stability and performance across a wide range of operating conditions.

Governor Control Linkage

Although primarily mechanical, the Governor Control Linkage benefits from the Speed Sensor’s data when integrated with electronic systems. This data helps in fine-tuning the linkage’s adjustments, leading to more precise engine control.

Governor Counter Assembly Linkage

The Governor Counter Assembly Linkage uses speed data from the sensor to ensure accurate counting and timing of engine cycles. This is particularly important in engines where precise timing is essential for performance and efficiency.

Governor Linkage

In systems where the Governor Linkage is used, the Speed Sensor’s data helps in making real-time adjustments to the linkage, ensuring the engine maintains the desired speed under varying loads.

Housing (Flywheel)

The Flywheel Housing often houses the Speed Sensor, providing a stable and accurate point for measuring engine speed. This ensures the sensor can deliver reliable data to the engine’s control systems.

Hydraulic Governor

Even in systems using a Hydraulic Governor, the Speed Sensor’s data can be used to enhance control precision. The sensor provides additional feedback that can be integrated into the hydraulic system’s control logic.

Linkage (Governor Control)

The Governor Control Linkage relies on accurate speed data from the sensor to make precise adjustments. This ensures the engine’s speed is maintained within the desired range, improving overall performance and reliability.

Module (Engine Control)

The Engine Control Module uses the Speed Sensor’s data to implement advanced control strategies. This includes managing variables like fuel injection, ignition timing, and turbo boost, leading to optimized engine performance.

System (Engine Monitoring)

In comprehensive Engine Monitoring systems, the Speed Sensor’s data is crucial for real-time monitoring and diagnostics. It allows for the detection of anomalies and the implementation of corrective actions, ensuring the engine operates within safe and efficient parameters.

Conclusion

The Cummins 3420946 Speed Sensor is a critical component in the efficient and safe operation of commercial trucks. By providing accurate rotational speed data, it enables precise control over various engine and vehicle systems, enhancing performance, fuel efficiency, and safety. Its robust design and compatibility with a range of Cummins engines make it a reliable choice for maintaining optimal engine performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.