5313864

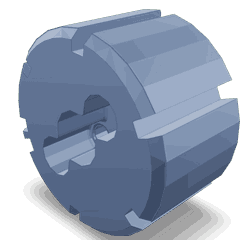

Speed Indicator Ring

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5313864 Speed Indicator Ring is a component designed for use in commercial trucks. Its primary role is to provide accurate rotational speed data of the engine, which is vital for both performance monitoring and diagnostic processes. This ring is part of the broader engine management system, ensuring that the engine operates within optimal parameters 1.

Function and Operation

The Speed Indicator Ring operates by interacting with sensors within the truck’s engine system. As the engine rotates, the ring passes by these sensors, generating signals that are used to calculate the rotational speed of the engine. This interaction is crucial for the engine control unit (ECU) to make real-time adjustments to fuel injection, ignition timing, and other parameters 2.

Purpose of the Speed Indicator Ring

The main purpose of the Speed Indicator Ring is to monitor and indicate the rotational speed of the engine. This data is essential for maintaining engine performance and for diagnostic purposes. By providing precise speed information, the ring helps in optimizing engine efficiency, ensuring smooth operation, and facilitating timely maintenance interventions 3.

Key Features

The Cummins 5313864 Speed Indicator Ring is characterized by its robust design and high-quality materials, which ensure durability and reliability under demanding conditions. The ring is engineered to withstand the harsh environments typical of commercial trucking, including exposure to high temperatures and vibrations. Its precise manufacturing tolerances ensure accurate speed readings, which are critical for engine management 4.

Benefits

The installation of the Speed Indicator Ring offers several advantages. It enhances engine performance monitoring by providing accurate speed data, which allows for better management of engine parameters. Additionally, it improves diagnostic capabilities, enabling technicians to identify and address issues more effectively. The ring also contributes to overall vehicle efficiency by ensuring that the engine operates within optimal speed ranges 5.

Installation and Compatibility

Proper installation of the Speed Indicator Ring is vital for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure it is correctly aligned with the sensors and other components. Compatibility with various truck models should be verified to ensure seamless integration into the engine system 6.

Maintenance and Troubleshooting

Regular maintenance of the Speed Indicator Ring is recommended to ensure its continued accurate operation. This includes periodic inspection for wear or damage and cleaning to remove any debris that may affect its performance. Common troubleshooting tips include checking for proper alignment and ensuring that the sensors are functioning correctly 7.

Safety Considerations

When working with the Speed Indicator Ring, it is important to observe safety protocols. This includes ensuring that the engine is turned off and cooled down before beginning any work. Additionally, appropriate personal protective equipment should be worn to prevent injury from moving parts or hot surfaces 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins is renowned for its high-quality engines and components, which are used in various applications, including commercial trucks. The company’s commitment to innovation and customer satisfaction has established it as a trusted name in the industry 9.

Cummins Speed Indicator Ring (Part 5313864) Compatibility

The Cummins Speed Indicator Ring, part number 5313864, is designed to interface with various engine systems, ensuring accurate speed readings and proper engine operation. This part is engineered to fit seamlessly within the specified engine models, providing reliable performance and durability 10.

ISBE4 CM850 Engine

The ISBE4 CM850 engine is one of the models that benefit from the integration of the Speed Indicator Ring. This engine is known for its robust design and high performance, making it suitable for demanding applications. The Speed Indicator Ring is meticulously crafted to align with the ISBE4 CM850’s specifications, ensuring that it functions optimally within the engine’s operational parameters 11.

Grouping of Engines

While the ISBE4 CM850 is a notable example, the Speed Indicator Ring is also compatible with other Cummins engines that share similar design and operational characteristics. This compatibility is achieved through precise engineering and adherence to industry standards, ensuring that the ring fits snugly and performs reliably across different engine models 12.

Conclusion

The Cummins 5313864 Speed Indicator Ring plays a significant role in the engine management system of commercial trucks. By providing accurate rotational speed data, it enhances engine performance, improves diagnostic capabilities, and contributes to overall vehicle efficiency. Proper installation, regular maintenance, and adherence to safety protocols are essential for the effective operation of this part. Cummins’ commitment to quality and precision ensures that the Speed Indicator Ring is a reliable and efficient component for various engine models.

-

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing Limited, 2011.

↩ -

Ling, Frederick F. The Automotive Body. Springer Science, 2011.

↩ -

Taghavifar, Hamid, and Aref Mardani. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩ -

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing Limited, 2011.

↩ -

Ling, Frederick F. The Automotive Body. Springer Science, 2011.

↩ -

Taghavifar, Hamid, and Aref Mardani. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩ -

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing Limited, 2011.

↩ -

Ling, Frederick F. The Automotive Body. Springer Science, 2011.

↩ -

Taghavifar, Hamid, and Aref Mardani. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.