This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

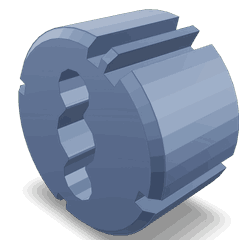

The Cummins 3970901 Speed Indicator Ring is a component designed for use in commercial trucks. It serves to monitor and indicate the rotational speed of specific components within the truck’s system. This part is integral to ensuring the accurate measurement and display of speed data, which is vital for the operation and maintenance of commercial vehicles 2.

Function and Operation

The Speed Indicator Ring operates by interacting with sensors within the truck’s system to measure the rotational speed of components such as the transmission or differential. It consists of a series of teeth or notches that pass by a sensor, generating electrical signals that are then converted into speed readings. This interaction allows for precise monitoring of the component’s rotational speed, which is crucial for various operational and diagnostic functions 1.

Purpose of the Speed Indicator Ring

The primary role of the Speed Indicator Ring is to provide accurate rotational speed data of specific truck components. This data is used for speedometer display, transmission shifting decisions, and various diagnostic functions. By ensuring that the speed data is accurate, the ring contributes to the overall efficiency and safety of the vehicle 2.

Key Features

The Cummins 3970901 Speed Indicator Ring is characterized by its durable design and precise engineering. It is typically made from high-strength materials to withstand the harsh conditions within a commercial truck’s drivetrain. The ring’s design includes a specific number of teeth or notches, tailored to the requirements of the truck’s system, ensuring accurate speed measurement 2.

Benefits

The Speed Indicator Ring offers several advantages, including enhanced monitoring capabilities and improved safety features. Accurate speed data allows for better transmission control, leading to more efficient operation and reduced wear on the drivetrain components. Additionally, precise speed monitoring contributes to safer driving conditions by ensuring that the speedometer displays accurate information 2.

Installation and Integration

Proper installation of the Speed Indicator Ring is crucial for its effective operation. It should be aligned correctly with the sensor to ensure accurate readings. Installation may require specific tools and knowledge of the truck’s system to avoid damage to the ring or sensor. It is also important to follow manufacturer guidelines for any necessary preparations or considerations during installation 2.

Troubleshooting and Maintenance

Common issues with the Speed Indicator Ring may include inaccurate speed readings or sensor malfunctions. Troubleshooting typically involves checking the alignment of the ring with the sensor, ensuring there is no damage to the teeth or notches, and verifying the sensor’s functionality. Regular maintenance, such as cleaning the ring and sensor, can help prevent issues and ensure optimal performance and longevity 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive industry. The company offers a wide range of products and services designed to meet the needs of commercial vehicle operators worldwide 2.

Speed Indicator Ring 3970901 Compatibility with Cummins Engines

The Speed Indicator Ring part number 3970901, manufactured by Cummins, is designed to fit a range of Cummins engines. This part is integral for the accurate measurement and display of engine speed, ensuring that operators have precise information about the engine’s performance 2.

ISB/ISD4.5 Series

- ISB/ISD4.5 CM2150 B119

- ISD4.5 CM2220 D108

The Speed Indicator Ring 3970901 is compatible with the ISB/ISD4.5 series engines, including the CM2150 B119 and CM2220 D108 variants. These engines are known for their reliability and efficiency, often used in a variety of applications from commercial vehicles to industrial machinery 2.

ISBE4 Series

- ISBE4 CM850

The ISBE4 CM850 engine also accommodates the Speed Indicator Ring 3970901. This engine is typically used in heavy-duty applications, providing robust performance and durability 2.

ISF3.8 Series

- ISF3.8 CM2220 AN

The ISF3.8 CM2220 AN engine is another model that can utilize the Speed Indicator Ring 3970901. This engine is often found in medium-duty trucks and buses, offering a balance of power and fuel efficiency 2.

QSB4.5 Series

- QSB4.5 CM2250 EC

- QSB4.5 CM850 (CM2850)

The QSB4.5 series engines, including the CM2250 EC and CM850 (CM2850) variants, are compatible with the Speed Indicator Ring 3970901. These engines are widely used in agricultural and construction equipment, known for their durability and high torque output 2.

QSL9 Series

- QSL9 CM850 (CM2850)

The QSL9 CM850 (CM2850) engine also fits the Speed Indicator Ring 3970901. This engine is typically used in heavy-duty applications, providing the necessary power for demanding tasks 2.

The Speed Indicator Ring 3970901 ensures that these Cummins engines operate smoothly and efficiently by providing accurate speed readings, which is crucial for maintaining performance and preventing potential engine issues 2.

Role of Part 3970901 Speed Indicator Ring in Engine Systems

The Speed Indicator Ring, part 3970901, is integral to the monitoring and regulation of engine performance. It interfaces with several key components to ensure accurate speed measurement and efficient operation 2.

Interaction with the Camshaft

The Speed Indicator Ring works in conjunction with the camshaft to provide precise rotational speed data. As the camshaft rotates, the ring’s markings pass a sensor, generating signals that are used to determine the engine’s RPM. This data is essential for synchronizing fuel injection and ignition timing, directly influencing the engine’s performance and efficiency 2.

Connecting Rod and Piston Dynamics

Accurate speed data from the indicator ring is vital for the proper functioning of the connecting rod and piston assembly. The ring’s feedback loop ensures that the piston’s movement is harmonized with the camshaft’s rotation, optimizing the power stroke and reducing mechanical wear 2.

Cylinder Head and Injector Coordination

In engines with overhead camshafts, the Speed Indicator Ring aids in the precise timing of valve operations within the cylinder head. This coordination is essential for efficient air-fuel mixture intake and exhaust processes. Additionally, the ring’s speed data is used to time the injector’s fuel delivery, ensuring that fuel is introduced into the combustion chamber at the optimal moment for maximum efficiency and power output 2.

Injector Plumbing and Long Block Integration

For engines with complex injector plumbing, the Speed Indicator Ring’s accurate speed readings are crucial. These readings help maintain consistent fuel pressure and flow rates throughout the injector system, preventing issues such as fuel starvation or over-fueling. In the context of a long block, which includes the cylinder block, crankshaft, pistons, and often the camshaft, the ring’s role in providing reliable speed data ensures that all these components operate in unison, enhancing overall engine performance and longevity 2.

Conclusion

The Cummins 3970901 Speed Indicator Ring is a critical component in the accurate measurement and display of rotational speed in commercial trucks. Its precise engineering, durable design, and compatibility with various Cummins engines make it an essential part for maintaining vehicle efficiency and safety. Proper installation, regular maintenance, and understanding its role in engine systems are key to maximizing the benefits of this Cummins part 2.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.