This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

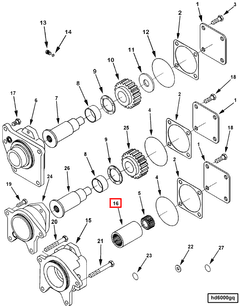

The Spline Coupling Sleeve, part number 4067907, manufactured by Cummins, is a critical component for heavy-duty trucks. This part ensures the efficient and reliable operation of the truck’s drivetrain. Cummins, a renowned name in the commercial truck industry, is known for producing high-quality components that enhance vehicle performance and durability.

Basic Concepts of Spline Coupling Sleeves

Spline coupling sleeves are mechanical components used in truck drivetrains to connect two shafts. Their splined design allows for torque transmission while accommodating slight misalignments between the connected shafts, ensuring smooth operation and reducing the risk of mechanical failure due to misalignment 1.

Purpose of the Spline Coupling Sleeve

The Spline Coupling Sleeve, part number 4067907, transmits torque between the engine and transmission or between other drivetrain components. It is designed to handle significant loads and stresses, ensuring efficient power transfer. Additionally, it accommodates minor misalignments, contributing to the overall reliability of the drivetrain 2.

Key Features

This Cummins part features a robust design with high-quality materials like hardened steel, enhancing durability and performance. It is precision-machined for a perfect fit and optimal performance. Design elements such as specialized coatings or treatments reduce friction and wear, contributing to its longevity and reliability in heavy-duty applications 3.

Benefits

The Spline Coupling Sleeve offers improved durability, crucial for heavy-duty trucks operating under demanding conditions. Its design enhances drivetrain performance by ensuring efficient torque transmission and accommodating misalignments. Additionally, its reliability reduces the likelihood of unexpected failures, contributing to the overall dependability of the truck.

Installation and Integration

Proper installation of the Spline Coupling Sleeve within the truck’s drivetrain is essential for its performance and longevity. Best practices include ensuring correct alignment and secure fastening. Following manufacturer guidelines helps avoid common installation challenges such as over-tightening or misalignment, which can lead to premature failure.

Troubleshooting and Maintenance

Common issues with the Spline Coupling Sleeve can often be traced to wear, corrosion, or improper installation. Regular maintenance, such as inspecting for signs of wear or corrosion and ensuring secure connections, can help prevent these issues. Following the manufacturer’s recommended maintenance schedule ensures optimal performance and longevity of the sleeve.

Common Failure Modes

Typical failure modes associated with spline coupling sleeves include wear due to friction, corrosion from exposure to moisture or chemicals, and damage from improper installation. Understanding these failure modes helps identify the root cause of issues and implement corrective actions to prevent future failures.

Diagnostic Techniques

Diagnostic techniques to identify issues with the Spline Coupling Sleeve include visual inspection for signs of wear or damage, torque testing to assess connection integrity, and analysis of operational data to identify patterns indicating impending failure. These techniques help in early detection of issues, allowing for timely maintenance or replacement.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications.

Compatibility of Cummins Spline Coupling Sleeve Part 4067907

The Cummins Spline Coupling Sleeve part number 4067907 is designed to fit seamlessly with several Cummins engine models. This part is integral in ensuring the smooth operation of the engine by connecting the transmission to the engine, allowing for the transfer of torque and rotational motion.

QST30 Engines

The QST30 engines, known for their robust performance and reliability, are compatible with the Spline Coupling Sleeve part 4067907. This part ensures that the engine’s transmission and engine are properly aligned, facilitating efficient power transfer and reducing wear and tear on the components.

CM552 Engines

Similarly, the CM552 engines benefit from the use of the Spline Coupling Sleeve part 4067907. This part is engineered to fit precisely within the CM552 engine’s design, providing a secure connection between the transmission and the engine. This ensures that the engine operates at optimal efficiency, maintaining the integrity of the power transfer mechanism.

Grouping of Compatible Engines

While the QST30 and CM552 engines are specifically mentioned, it is important to note that the Spline Coupling Sleeve part 4067907 is designed to be compatible with a broader range of Cummins engines. These engines are typically part of the same family or series, sharing similar design principles and specifications that allow for the interchangeability of parts like the Spline Coupling Sleeve.

By ensuring that the Spline Coupling Sleeve part 4067907 is correctly installed, engine performance and longevity can be significantly enhanced. This part is a critical component in the engine’s overall functionality, and its compatibility with multiple engine models underscores its versatility and importance in maintaining engine efficiency.

Role of Part 4067907 Spline Coupling Sleeve in Engine Systems

The Spline Coupling Sleeve, part number 4067907, is an integral component in the efficient operation of various engine systems, particularly in the context of the drive and auxiliary pump mechanisms.

Drive Mechanism

In the drive mechanism, the Spline Coupling Sleeve ensures a secure and flexible connection between rotating components. This allows for the transmission of torque from the engine to the driven components, such as the crankshaft or camshaft, without the risk of slippage or misalignment. The sleeve’s splined design provides a robust interface that can accommodate minor axial and radial movements, which are common in dynamic engine environments. This results in smoother operation and reduced wear on connected parts.

Auxiliary Pump System

Within the auxiliary pump system, the Spline Coupling Sleeve plays a significant role in maintaining the integrity of the fluid transfer process. It connects the pump to the drive shaft, enabling the pump to operate in sync with the engine’s rotational speed. The sleeve’s design allows for efficient power transmission while accommodating the pump’s operational requirements, such as variable speed and load conditions. This ensures that the auxiliary pump can deliver consistent performance, whether it is used for fuel injection, lubrication, or cooling systems.

Overall, the Spline Coupling Sleeve enhances the reliability and efficiency of both the drive and auxiliary pump systems by providing a durable and flexible connection that can withstand the rigors of engine operation.

Conclusion

The Spline Coupling Sleeve, part number 4067907, is a vital component in the drivetrain of heavy-duty trucks, ensuring efficient and reliable operation. Its robust design, compatibility with various Cummins engines, and role in both drive and auxiliary pump systems highlight its importance in maintaining engine performance and longevity. Proper installation, regular maintenance, and understanding common failure modes are essential for maximizing the benefits of this Cummins part.

-

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Caines, Arthur J., Haycock, Roger F., & Hillier, John E. Automotive Lubricants Reference Book. SAE International, 2004.

↩ -

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.