3074279

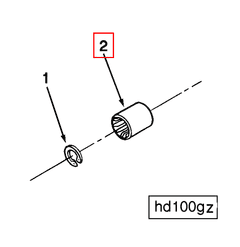

Spline Coupling Sleeve

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Spline Coupling Sleeve, part number 3074279, manufactured by Cummins, is a critical component for heavy-duty trucks. This Cummins part ensures the efficient operation of the truck’s drivetrain by facilitating the transmission of torque between two shafts. Cummins is renowned for producing reliable and high-performance components, and this part is no exception.

Basic Concepts

Spline coupling sleeves are mechanical components designed to transmit torque between two shafts. Their splined design allows for a secure connection capable of handling significant rotational forces. In a truck’s drivetrain, these sleeves interface with various components, ensuring smooth and efficient power transfer from the engine to the wheels 1.

Purpose of the Spline Coupling Sleeve

The Spline Coupling Sleeve is integral to the operation of a truck’s drivetrain. Positioned between rotating components, it allows for the transfer of torque while accommodating minor misalignments. This part interacts with other components such as the transmission and differential, maintaining the integrity and efficiency of the drivetrain system 2.

Key Features

This Cummins part is constructed from high-quality materials, ensuring durability and performance in demanding conditions. Its design specifications include precise spline geometry, which enhances the connection’s strength and reliability. Additionally, the sleeve may feature unique attributes such as corrosion-resistant coatings or enhanced lubrication channels to improve its operational lifespan 3.

Benefits

The Spline Coupling Sleeve offers several advantages in heavy-duty applications. It provides improved torque transmission, ensuring that power is efficiently transferred throughout the drivetrain. The sleeve’s durable construction contributes to the overall reliability of the truck, while its design may also enhance the efficiency of the drivetrain system.

Installation Process

Proper installation of the Spline Coupling Sleeve involves several steps. Begin by ensuring that the mating surfaces are clean and free of debris. Align the splines on the sleeve with those on the shafts, and gently press the sleeve into place. It is important to follow manufacturer guidelines to avoid over-tightening, which could damage the splines. Additionally, verify that the sleeve is properly seated and that there is no excessive play.

Common Issues and Troubleshooting

Frequent problems with spline coupling sleeves can include wear on the splines, misalignment, or contamination. To diagnose these issues, inspect the sleeve for signs of damage or corrosion. If misalignment is suspected, check the positioning of the connected components. Contamination can often be addressed by cleaning the sleeve and ensuring that it is properly lubricated.

Maintenance Tips

Regular maintenance of the Spline Coupling Sleeve is important for ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, and ensuring that the sleeve is properly lubricated. Adhering to recommended inspection intervals and lubrication schedules will help maintain the sleeve’s condition and efficiency.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry. The company’s product range includes a variety of components for heavy-duty trucks, reflecting its commitment to providing reliable and high-performance solutions.

Spline Coupling Sleeve (Part 3074279) in Cummins Engines

The Spline Coupling Sleeve, identified by the part number 3074279, is a critical component in Cummins engines, ensuring the seamless transfer of torque between the engine and other drivetrain components. This part is integral to the proper functioning of the engine’s mechanical systems.

N14 Celect Plus Engine

In the N14 Celect Plus engine, the Spline Coupling Sleeve plays a pivotal role in connecting the engine to the transmission. This engine is known for its robust design and high performance, often used in heavy-duty applications. The spline coupling sleeve ensures that the rotational force from the engine is efficiently transmitted to the transmission, maintaining the integrity of the drivetrain.

Cummins Engine Group

The Spline Coupling Sleeve (3074279) is designed to fit seamlessly within the Cummins engine group, which includes a variety of models known for their reliability and durability. This part is engineered to meet the stringent requirements of Cummins engines, ensuring compatibility and performance across different engine types within the group.

Application and Importance

The Spline Coupling Sleeve is essential for maintaining the alignment and connection between the engine and transmission. It features precision-machined splines that interlock with corresponding splines on the transmission, preventing slippage and ensuring a stable power transfer. This component is critical in maintaining the overall efficiency and longevity of the engine system.

Installation and Maintenance

Proper installation of the Spline Coupling Sleeve is crucial to avoid any misalignment or damage to the engine or transmission. Regular maintenance checks should be performed to ensure that the splines remain free of wear and damage, as any issues with this component can lead to significant drivetrain problems.

Role of Part 3074279 Spline Coupling Sleeve in Engine Systems

The 3074279 Spline Coupling Sleeve is an integral component in the synchronization of various engine systems, particularly when interfacing with pumps and auxiliary components.

In systems where pumps are utilized, the Spline Coupling Sleeve ensures a seamless transfer of rotational force from the engine to the pump. This transfer is vital for the pump’s operation, allowing it to maintain consistent fluid flow rates and pressures. The spline design of the coupling sleeve provides a robust connection, accommodating minor misalignments between the engine and pump, which can occur due to thermal expansion or manufacturing tolerances.

When connecting to auxiliary components, the 3074279 Spline Coupling Sleeve plays a similar role. It facilitates the efficient transmission of power to these components, ensuring they operate in sync with the engine’s rotational speed. This is particularly important for components that require precise timing, such as variable valve timing systems or superchargers.

The Spline Coupling Sleeve’s design also allows for easy installation and removal, making maintenance and repairs more straightforward. Its durability under varying operational conditions ensures long-term reliability in engine systems.

Conclusion

The 3074279 Spline Coupling Sleeve is a vital component in the efficient operation of heavy-duty truck drivetrains. Its role in transmitting torque, accommodating misalignments, and ensuring the smooth operation of engine systems underscores its importance. Proper installation, regular maintenance, and understanding its function within the engine system are key to maximizing its performance and longevity.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Kasab, John, and Andrea Strzelec. Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International, 2020.

↩ -

Denton, Tom, and Hayley Pells. Automotive Technician Training Theory. Routledge, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.