This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 102297 Spring Retainer is a component designed for use in commercial trucks. It serves a specific function within the engine’s valve train system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is key to maintaining the optimal performance of commercial trucks.

Basic Concepts of Spring Retainers

A spring retainer is a mechanical component that holds valve springs in place within an engine. Its primary function is to ensure that the valve springs remain correctly positioned and operational. In the context of a truck’s engine, the spring retainer plays a role in maintaining the integrity of the valve train system by securing the valve springs, which are responsible for returning the valves to their closed position after being opened by the camshaft 1.

Purpose of the Cummins 102297 Spring Retainer

This Cummins part is integral to the operation of a truck’s engine. It is specifically designed to work within the valve train system, where it secures the valve springs. This ensures that the valves open and close at the correct times, which is vital for the engine’s combustion process. By maintaining the proper function of the valve springs, the spring retainer contributes to the engine’s overall performance and efficiency 2.

Key Features

The Cummins 102297 Spring Retainer is characterized by several key features that enhance its performance. It is made from high-quality materials, ensuring durability and resistance to wear. The design of the retainer is optimized for its specific function within the engine, featuring precise dimensions and a robust construction. These attributes contribute to its reliability and effectiveness in securing the valve springs 3.

Benefits

The use of the Cummins 102297 Spring Retainer offers several benefits. It contributes to improved engine efficiency by ensuring that the valve springs function correctly. This leads to better valve operation, which is crucial for the engine’s combustion process. Additionally, the durability and reliability of the spring retainer enhance the overall performance and longevity of the engine 4.

Installation Process

Installing the Cummins 102297 Spring Retainer requires careful attention to detail. The process involves placing the retainer over the valve springs and ensuring it is correctly positioned. Tools such as spring compressors may be required to hold the springs in place during installation. It is important to follow manufacturer guidelines to ensure the retainer is fitted correctly, which will contribute to the engine’s optimal performance.

Troubleshooting Common Issues

Common issues with spring retainers can include wear and tear or malfunction due to improper installation. Symptoms may include engine misfires or reduced performance. Troubleshooting steps involve inspecting the retainer for signs of damage or wear, ensuring it is correctly installed, and replacing it if necessary to maintain engine efficiency.

Maintenance Tips

Regular maintenance of the Cummins 102297 Spring Retainer is important for ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or damage and cleaning to remove any debris that may affect its function. Adhering to recommended inspection intervals and maintenance procedures will help to preserve the integrity of the valve train system.

Role in Engine Performance

The Cummins 102297 Spring Retainer plays a significant role in engine performance by ensuring the proper function of the valve springs. This contributes to the precise timing of valve operation, which is crucial for the engine’s combustion efficiency. By maintaining the integrity of the valve train system, the spring retainer helps to enhance the overall performance and reliability of the engine.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and a diverse product range, Cummins is renowned for its quality and reliability in the commercial truck industry. The company’s commitment to excellence is reflected in its components, including the Cummins 102297 Spring Retainer.

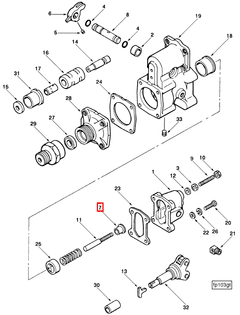

Spring Retainer Part 102297 in Cummins Engines

The Spring Retainer part 102297, manufactured by Cummins, is a critical component in the engine systems of various Cummins engines. This part is designed to securely hold springs in place, ensuring the proper functioning of the engine’s mechanisms.

In the K38 engine series, the Spring Retainer part 102297 plays a vital role in maintaining the integrity of the engine’s spring-loaded components. Its precise fit and robust construction are essential for the engine’s operational efficiency and longevity.

Similarly, in the K50 engine series, the Spring Retainer part 102297 is integral to the engine’s design. This part ensures that the springs are held firmly, preventing any movement that could lead to mechanical failures or inefficiencies.

Both the K38 and K50 engines benefit from the reliability and precision of the Spring Retainer part 102297, highlighting its importance in the overall performance and durability of these engines.

Role of Part 102297 Spring Retainer in Engine Systems

The Part 102297 Spring Retainer is an integral component in various engine systems, ensuring the proper functioning and regulation of several critical elements.

In the fuel system, the Spring Retainer works in conjunction with the Fuel Pump and Fuel Pump Governor. It helps maintain the necessary pressure and flow rates by securing the Spring Pack within the Governor Housing. This ensures that the Fuel Pump and Drive mechanism operates efficiently, delivering consistent fuel to the engine.

For the Turbocharger Fuel Pump (F.P.) kit, the Spring Retainer is essential in the Governor Cover and Governor Spring Cover. It secures the Spring Turbocharger Governor Pack, which regulates the turbocharger’s performance by controlling the fuel supply. This interaction is vital for optimizing the turbocharger’s efficiency and responsiveness.

In the Torque Converter Governor Spring Pack, the Spring Retainer plays a role in maintaining the integrity of the spring assembly within the T C Governor Housing. This ensures that the torque converter operates smoothly, transferring power effectively from the engine to the transmission.

Additionally, in systems involving Fuel Injection and Fuel Pump, the Spring Retainer secures the Spring Pack and Spring Pack Cover, ensuring that the injection timing and pressure are accurately controlled. This is particularly important in high-performance engines where precision in fuel delivery directly impacts engine performance and efficiency.

Overall, the Part 102297 Spring Retainer is a key component in securing and maintaining the functionality of spring-based governor systems across various engine applications.

Conclusion

The Cummins 102297 Spring Retainer is a vital component in the valve train system of commercial truck engines. Its role in securing valve springs ensures precise valve operation, contributing to engine efficiency and reliability. Regular maintenance and proper installation are essential to maximize the performance and longevity of this part.

-

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles (Second Edition). SAE International.

↩ -

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩ -

Mom, G. (2023). The Evolution of Automotive Engineering: A Handbook. SAE International.

↩ -

Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.