This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

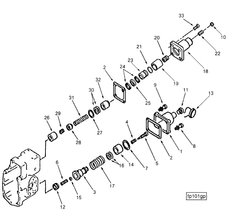

The Idle Spring Plunger Guide, identified by part number 3038216, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This guide plays a role in the efficient operation of heavy-duty trucks by ensuring the proper function of the idle system within the engine. Understanding its significance and operation can contribute to maintaining the overall performance and longevity of the vehicle 1.

Function and Operation

The Idle Spring Plunger Guide operates within the engine system by facilitating the movement of the idle spring plunger. This component interacts with various engine parts, including the throttle mechanism and the fuel injection system. Its role is to maintain consistent engine idle speed by guiding the plunger, which in turn helps in regulating the air and fuel mixture during idle conditions. This ensures that the engine runs smoothly without unnecessary strain or fluctuations in RPM 2.

Key Features

The Idle Spring Plunger Guide is designed with precision to meet the demanding requirements of heavy-duty truck engines. It is constructed from durable materials that can withstand high temperatures and mechanical stress. Key features include its robust build, which ensures longevity, and its precise engineering, which allows for smooth operation within the engine system. Additionally, the guide is designed to be compatible with Cummins engines, ensuring optimal performance and reliability 3.

Benefits

Incorporating the Idle Spring Plunger Guide into the engine system offers several advantages. It contributes to improved engine efficiency by ensuring that the idle system operates within specified parameters. This can lead to reduced wear on engine components, as the guide helps maintain consistent engine performance under idle conditions. Furthermore, the guide enhances the overall performance of the truck by promoting a stable and efficient idle, which is crucial for operations that require the engine to run for extended periods without load 4.

Installation Process

Proper installation of the Idle Spring Plunger Guide is crucial for ensuring optimal performance. The process involves several steps: first, the engine must be prepared by ensuring it is clean and free of any debris. Next, the guide should be aligned with the idle spring plunger and secured in place according to the manufacturer’s specifications. It is important to follow the installation instructions carefully to avoid any misalignment that could affect engine performance. After installation, the engine should be tested to ensure that the idle system is functioning correctly 5.

Common Issues and Troubleshooting

Typical problems associated with the Idle Spring Plunger Guide may include wear or damage to the guide, which can affect the operation of the idle system. Symptoms of issues may include irregular idle speed or difficulty in maintaining a stable idle. Troubleshooting steps involve inspecting the guide for signs of wear or damage and ensuring that it is properly aligned and secured. If necessary, the guide should be replaced to restore proper function to the idle system 6.

Maintenance Tips

Regular maintenance of the Idle Spring Plunger Guide is important for prolonging its lifespan and ensuring continued reliable operation. This includes periodic inspection for signs of wear or damage, cleaning the guide to remove any buildup that could affect its function, and ensuring that it remains properly aligned within the engine system. Following these maintenance practices can help prevent issues with the idle system and contribute to the overall efficiency and performance of the truck 7.

Cummins Overview

Cummins is a reputable manufacturer in the automotive and heavy-duty truck industry, known for producing high-quality components that meet the demanding requirements of these applications. With a history of innovation and commitment to excellence, Cummins has established itself as a leader in the field. The company’s dedication to quality and performance is evident in its wide range of products, including the Idle Spring Plunger Guide, which is designed to enhance the operation and efficiency of heavy-duty truck engines 8.

Role of Part 3038216 Idle Spring Plunger Guide in Engine Systems

The Idle Spring Plunger Guide, identified by part number 3038216, is an integral component within the engine system, particularly in the context of fuel management and calibration. This guide ensures the precise operation of the idle spring plunger, which is essential for maintaining the engine’s idle speed and stability.

Integration with Fuel System Components

-

Fuel Pump: The Idle Spring Plunger Guide works in conjunction with the fuel pump to regulate the fuel supply. By guiding the plunger, it helps in maintaining consistent fuel pressure, which is vital for the fuel pump’s efficient operation 9.

-

Fuel Calibration: Accurate calibration of the fuel system is dependent on the stable operation of the Idle Spring Plunger Guide. It ensures that the fuel delivery matches the engine’s requirements during idle, preventing issues such as stalling or rough idling 10.

-

Calibration Code: The guide is often referenced in calibration codes that dictate the engine’s performance parameters. Proper functioning of the guide is necessary to achieve the desired calibration settings, ensuring optimal engine performance 11.

-

Fuel Pump Calibration: When calibrating the fuel pump, the Idle Spring Plunger Guide plays a role in fine-tuning the fuel delivery system. It assists in achieving the precise fuel flow rates necessary for both idle and operational conditions 12.

-

Fuel Code: The fuel code, which includes various parameters like fuel pressure and delivery rates, relies on the consistent performance of the Idle Spring Plunger Guide to ensure that the engine operates within specified limits 13.

-

Fuel Pump Code: Similarly, the fuel pump code, which outlines the operational characteristics of the fuel pump, depends on the guide to maintain the integrity of the fuel supply system during idle 14.

Importance in Engine Calibration

The Idle Spring Plunger Guide is a key component in the engine’s calibration process. It ensures that the idle spring plunger operates within the designed parameters, which is essential for:

- Consistent Idle Speed: By guiding the plunger, it helps maintain a stable idle speed, which is critical for smooth engine operation 15.

- Fuel Efficiency: Proper guidance of the plunger contributes to efficient fuel usage, especially during idle conditions 16.

- Engine Stability: It plays a role in preventing fluctuations in engine speed, which can lead to instability and potential damage 17.

Conclusion

In summary, the Idle Spring Plunger Guide (part 3038216) is a vital component that ensures the smooth and efficient operation of the engine’s fuel system, particularly during idle. Its role in calibration and fuel management underscores its importance in maintaining engine performance and reliability.

-

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Denton, Tom and Pells, Hayley. Automotive Technician Training Theory. Routledge, 2022.

↩ -

Drozdziel, Pawel. The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge, 2023.

↩ -

Cummins Inc. Operation and Maintenance Manual for ISB6.7 CM2250. Bulletin Number 4022263.

↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Denton, Tom and Pells, Hayley. Automotive Technician Training Theory. Routledge, 2022.

↩ -

Drozdziel, Pawel. The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge, 2023.

↩ -

Cummins Inc. Operation and Maintenance Manual for ISB6.7 CM2250. Bulletin Number 4022263.

↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Denton, Tom and Pells, Hayley. Automotive Technician Training Theory. Routledge, 2022.

↩ -

Drozdziel, Pawel. The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge, 2023.

↩ -

Cummins Inc. Operation and Maintenance Manual for ISB6.7 CM2250. Bulletin Number 4022263.

↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Denton, Tom and Pells, Hayley. Automotive Technician Training Theory. Routledge, 2022.

↩ -

Drozdziel, Pawel. The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge, 2023.

↩ -

Cummins Inc. Operation and Maintenance Manual for ISB6.7 CM2250. Bulletin Number 4022263.

↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.