This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

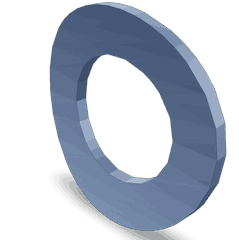

The Spring Washer 3337631, manufactured by Cummins, is a specialized component designed for use in commercial trucks. This part plays a significant role in ensuring the reliability and efficiency of various mechanical assemblies within these vehicles.

Basic Concepts of Spring Washers

Spring washers, also known as lock washers, are mechanical devices used to prevent fastening components from loosening due to vibration or fluctuating loads. They function by applying a constant tension to the fastener, which helps maintain a secure connection. Spring washers are commonly used in conjunction with bolts, nuts, and screws in a wide range of applications to enhance the stability and durability of the assembly 1.

Purpose of Spring Washer 3337631 in Truck Operation

The Spring Washer 3337631 is specifically engineered to address the unique demands of commercial truck operations. In truck fastening systems, this washer helps to distribute loads more evenly across the fastener, reducing the risk of loosening under dynamic conditions. Its application is particularly important in areas where vibrations are common, such as in the engine compartment or undercarriage of the truck 2.

Key Features

The Spring Washer 3337631 boasts several distinctive characteristics that enhance its functionality. It is typically made from high-strength materials, ensuring durability under heavy loads. The design of the washer includes a helical coil that provides the necessary tension to keep fasteners secure. Additionally, its unique attributes may include corrosion resistance and compatibility with a variety of fastener sizes, making it a versatile component in truck maintenance 3.

Benefits of Using Spring Washer 3337631

Incorporating the Spring Washer 3337631 into truck assemblies offers several advantages. It improves load distribution across the fastener, which can lead to more reliable connections. The washer also provides vibration damping, which is crucial in the harsh operating environments of commercial trucks. Furthermore, its resistance to loosening ensures that fastening systems remain secure over time, reducing the need for frequent maintenance 4.

Installation Guidelines

To ensure optimal performance and longevity, the Spring Washer 3337631 should be installed according to specific guidelines. Begin by selecting the appropriate fastener size to match the washer. Place the washer under the nut or bolt head, ensuring it is correctly oriented to apply tension. Tighten the fastener to the manufacturer’s recommended torque specifications, taking care not to over-tighten, which could damage the washer or the fastener .

Troubleshooting Common Issues

Frequent problems associated with spring washers include wear and tear or improper installation. If a washer shows signs of deformation or corrosion, it should be replaced to maintain the integrity of the fastening system. Improper installation, such as incorrect orientation or over-tightening, can also lead to issues. Regular inspection and adherence to installation guidelines can help prevent these problems .

Maintenance Tips

Regular inspection and maintenance of the Spring Washer 3337631 are recommended to prolong its service life and ensure continued reliable performance. Inspect the washer for signs of wear, corrosion, or deformation during routine maintenance checks. Replace the washer as needed to maintain the security of the fastening system. Additionally, ensure that all fasteners are tightened to the correct specifications to prevent over-tightening or under-tightening .

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality and innovation in the automotive industry. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial and industrial applications .

Role of Part 3337631 Spring Washer in Engine Systems

The 3337631 Spring Washer is an essential component in various engine systems, contributing to the efficient operation and durability of several key assemblies.

In the air outlet pipe arrangement, the spring washer ensures a secure and vibration-resistant connection, maintaining the integrity of the air flow path.

For the turbocharger assembly, it plays a role in the mounting process, providing additional tension to prevent loosening under high-stress conditions.

In the assembly flange of the coolant heater starting aid, the spring washer enhances the sealing capability, ensuring consistent heat transfer during cold starts.

When integrated into the cover of the valve mechanism, it helps in maintaining proper valve seating by counteracting spring compression forces.

Within the cylinder assembly block and cylinder head cover, the spring washer supports bolt tension, crucial for preventing leaks and ensuring a tight seal around combustion chambers.

In the drive and front gear train accessory, it assists in maintaining consistent tension on bolts, which is vital for the smooth operation of accessory drives.

For the exchanger heat and filter assembly bracket, the spring washer ensures that connections remain tight, even under thermal expansion and contraction cycles.

In the fuel injection assembly pump and gas prechamber assembly, it contributes to the secure attachment of components, which is essential for precise fuel delivery and combustion efficiency.

The module engine control and module gas pump benefit from the spring washer by ensuring electrical connections remain firm, reducing the risk of intermittent faults.

In the water assy (gilkes), single fuel filter assembly, and starter motor assembly, it provides additional clamping force, which is important for the reliable operation of these systems.

For the starting assembly motor and system engine monitoring, the spring washer ensures that sensor and actuator mounts remain stable, providing accurate readings and consistent performance.

In the thermostat mounting housing, it helps in maintaining a secure fit, which is necessary for proper thermostat function and coolant flow regulation.

Lastly, in the water assembly pump, water connection, water outlet connection, and general water pump applications, the spring washer ensures that water passages remain sealed, preventing leaks and ensuring efficient coolant circulation .

Conclusion

The Spring Washer 3337631 by Cummins is a vital component in the maintenance and operation of commercial trucks and various engine systems. Its design and functionality contribute to the reliability, durability, and efficiency of mechanical assemblies, making it an indispensable part in the automotive and heavy-duty truck industry.

-

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ -

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩ -

Department of Energy. Department of Energy Fundamentals Handbook. Department of Energy, 2015.

↩ -

Cummins Inc. ISC8.3 and ISL9 CM2250 Service Manual (4022257). Cummins Inc., 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.