This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

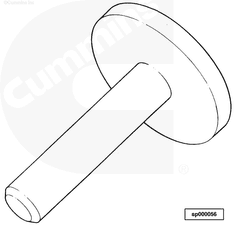

The Spring Compressor Plate 3375705, manufactured by Cummins, is a critical component in the suspension systems of heavy-duty trucks. Cummins, a prominent figure in the automotive and heavy-duty truck industries, is renowned for its commitment to quality and innovation, which is reflected in the reliability and effectiveness of this part 1.

Basic Concepts and Functionality

Spring compressor plates, including the 3375705, are engineered to manage the forces exerted by suspension springs. They compress the springs during vehicle operation, which is essential for maintaining the alignment and integrity of the suspension system. This Cummins part interacts with other suspension components, such as leaf springs and axles, to ensure smooth and stable truck performance 2.

Purpose and Role in Truck Operation

The primary role of the Spring Compressor Plate 3375705 in heavy-duty trucks is to support the suspension system. It ensures optimal suspension performance, which is vital for load handling and overall vehicle stability. By maintaining proper compression and alignment of the springs, this plate enhances the truck’s ability to carry heavy loads without compromising ride quality or safety 3.

Key Features

This part is distinguished by several key features that enhance its performance and durability. It is constructed from high-strength materials, ensuring it can withstand the rigors of heavy-duty truck operations. The design includes precise engineering to fit seamlessly within the suspension system, and it may feature unique characteristics such as corrosion resistance or enhanced load-bearing capabilities.

Benefits

Incorporating the Spring Compressor Plate 3375705 into a truck’s suspension system offers several advantages. It contributes to improved ride quality by ensuring the suspension system operates smoothly under various load conditions. Additionally, it enhances the truck’s load-carrying capacity and may contribute to fuel efficiency by maintaining optimal suspension performance. These benefits collectively contribute to the overall performance and longevity of the truck.

Installation and Integration

Proper installation of the Spring Compressor Plate 3375705 is crucial for its effective operation. The process involves preparing the suspension system, using the appropriate tools, and following specific steps to integrate the plate seamlessly. Careful attention to these procedures ensures that the plate functions as intended within the suspension system.

Troubleshooting and Maintenance

Regular maintenance and timely troubleshooting are important for the longevity and performance of the Spring Compressor Plate 3375705. Common issues may include wear and tear or misalignment, which can be identified through routine inspections. Diagnostic procedures and maintenance practices, such as cleaning and lubrication, help in prolonging the lifespan of the plate and ensuring continued optimal performance.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive and heavy-duty truck industries, known for its commitment to quality and innovation. With a diverse product portfolio that includes engines, filtration systems, and aftermarket parts, Cummins has established a strong reputation for delivering reliable and high-performance components. The company’s history of excellence and dedication to advancing technology underscores the quality of its products, including the Spring Compressor Plate 3375705.

Conclusion

The Spring Compressor Plate 3375705 by Cummins plays a significant role in the suspension systems of heavy-duty trucks. Its design, functionality, and integration into the suspension system contribute to improved ride quality, enhanced load-carrying capacity, and overall vehicle performance. Regular maintenance and proper installation are key to ensuring the longevity and effectiveness of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.