This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

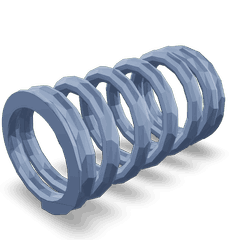

The Cummins 3411340 Injector Spring is a vital component in the fuel injection system of diesel engines, particularly in commercial trucks. This part ensures precise control of fuel injection, which is essential for efficient engine operation. The spring’s role in maintaining correct fuel pressure and timing contributes significantly to engine performance and efficiency 1.

Function and Operation

Within the fuel injection system, the injector spring controls the movement of the injector needle. As fuel pressure builds, the spring compresses, allowing the needle to open and inject fuel into the combustion chamber. When pressure drops, the spring returns the needle to its closed position, halting fuel flow. This precise cycle is crucial for maintaining engine performance and efficiency 2.

Purpose of the 3411340 Injector Spring

The Injector Spring enhances fuel efficiency, engine performance, and emissions control. By ensuring optimal fuel injection pressure and timing, it promotes more complete combustion, leading to improved fuel economy. Precise fuel delivery also reduces emissions by minimizing unburned fuel and promoting cleaner combustion 3.

Key Features

Designed for durability and performance, the 3411340 Injector Spring is made from high-quality materials to withstand the high pressures and temperatures of the fuel injection system. Its design ensures consistent performance over time, with features like a specific rate of compression tailored to diesel engine demands 4.

Benefits

Using the 3411340 Injector Spring offers several advantages, including improved fuel economy, enhanced engine performance, reduced emissions, and increased reliability due to its durable construction. These benefits contribute to the overall effectiveness and longevity of the diesel engine.

Installation and Maintenance

Proper installation and maintenance of the Injector Spring are crucial for optimal performance and longevity. Installation should adhere to manufacturer guidelines, using recommended tools and procedures. Regular maintenance, including inspection for wear or damage and timely replacement, is essential for maintaining the spring’s effectiveness and preventing engine issues.

Troubleshooting Common Issues

Common issues with the 3411340 Injector Spring may include reduced engine performance, increased fuel consumption, or higher emissions. These problems often stem from wear or failure of the spring. Troubleshooting involves inspecting the spring for damage, testing the fuel injection system for proper pressure and timing, and replacing the spring if necessary. Prompt attention to these issues helps maintain engine efficiency and performance.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, renowned in the commercial truck industry for its commitment to innovation, quality, and customer satisfaction. The company’s wide range of products, including the 3411340 Injector Spring, is designed to meet the demands of various applications, ensuring reliable and efficient engine performance.

Compatibility

The Cummins Injector Spring (part 3411340) is compatible with various engine models, including N14 CELECT PLUS, QSN14 CM876 N103, and QSNT14 CM876 N102 engines. This compatibility underscores its importance in maintaining the performance and reliability of Cummins engines.

Role in Engine Systems

The Injector Spring (part 3411340) is integral to the fuel injection system, managing precise fuel delivery into the combustion chamber. It works in conjunction with the injector, cylinder head, connecting rod, and piston to ensure optimal engine performance and efficiency. For engines with performance modifications, the spring’s role becomes even more critical, ensuring efficient operation under enhanced conditions.

Conclusion

The Cummins 3411340 Injector Spring is a crucial component in diesel engine fuel injection systems. Its precise control of fuel injection pressure and timing significantly impacts engine performance, efficiency, and emissions. Proper installation, maintenance, and timely troubleshooting are essential for maximizing the benefits of this part.

-

Alma Hillier, Fundamentals of Motor Vehicle Technology Book 1 6th Edition, Oxford University Press, 2014.

↩ -

Allan Bonnick, A Practical Approach to Motor Vehicle Engineering and Maintenance, Elsevier, 2004.

↩ -

Daniel Williams, Generalized Vehicle Dynamics, SAE International, 2022.

↩ -

Paul Dempsey, Troubleshooting and Repairing Diesel Engines, 5th Edition, McGraw-Hill, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.