This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

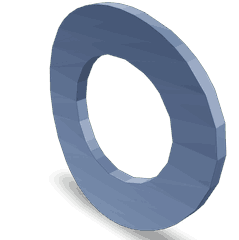

The Cummins Part #3420854 Spring Washer is a specialized component designed for use in commercial trucks and various engine systems. Its primary role is to enhance the reliability and performance of bolted connections by maintaining consistent bolt tension and preventing loosening. This contributes to the overall durability and safety of truck operations and engine performance 1.

Basic Concepts of Spring Washers

A spring washer, also known as a lock washer, is a type of washer designed with a helical or spiral shape. Its function is to provide additional tension to bolted connections, which helps to prevent loosening due to vibration or other dynamic forces. Spring washers are commonly used in mechanical systems where secure fastening is crucial, such as in automotive, aerospace, and heavy-duty truck applications 2.

Purpose of the 3420854 Spring Washer in Truck Operations

This Cummins part plays a significant role in the operation of commercial trucks by ensuring that bolted connections remain tight and secure. It achieves this by exerting a constant spring force on the bolt, which counters the effects of vibration and thermal expansion that can lead to loosening. This consistent tension helps maintain the integrity of critical truck components, enhancing safety and performance 3.

Key Features of the 3420854 Spring Washer

This part is characterized by its unique design and material properties. It is typically made from high-strength steel, which provides durability and resistance to wear. The spring properties of the washer allow it to flex and apply continuous pressure to the bolt, ensuring a secure fit. Additionally, its dimensional specifications are precisely engineered to fit a variety of bolt sizes commonly used in commercial trucks.

Benefits of Using the 3420854 Spring Washer

The use of this part offers several advantages in truck operations. It enhances load distribution across the bolted connection, which reduces the risk of failure under stress. The washer’s design also improves vibration resistance, making it ideal for use in dynamic environments. Furthermore, it contributes to prolonged fastening integrity, ensuring that critical components remain securely attached over time.

Installation Guidelines for the 3420854 Spring Washer

Proper installation of this part is vital for its effective function. To install, place the spring washer under the bolt head or nut, ensuring it is correctly aligned with the bolt thread. Tighten the bolt to the manufacturer’s specified torque settings to achieve the desired tension. It is important to avoid over-tightening, which can damage the washer or the bolted connection. Regular inspection during maintenance checks can help identify any signs of wear or damage.

Troubleshooting Common Issues with Spring Washers

Common issues with spring washers include failure to maintain tension and corrosion. If a spring washer fails to maintain tension, it may be due to improper installation or excessive wear. In such cases, replacing the washer and ensuring correct installation procedures are followed can resolve the issue. Corrosion can be addressed by using spring washers made from corrosion-resistant materials or by applying protective coatings.

Maintenance Tips for Spring Washers

Regular inspection and maintenance of spring washers are important for ensuring optimal performance and longevity. Inspect washers during routine maintenance checks for signs of wear, deformation, or corrosion. Replace any damaged washers promptly to maintain the integrity of the bolted connections. Additionally, ensure that bolts are tightened to the correct torque settings to prevent over-tightening or under-tightening, which can affect the performance of the spring washer.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its high-quality products and innovative technologies. The company’s commitment to excellence and customer satisfaction has established it as a trusted name in the industry.

Role of Part 3420854 Spring Washer in Engine Systems

This part is an essential component in various engine systems, contributing to the efficient operation and durability of these systems. Here’s how it integrates with several key components:

Air and Fuel Systems

In the Air Fuel Assembly Mixer and Assembly Mixer Air Fuel, the Spring Washer ensures a secure connection between components, maintaining the integrity of the air-fuel mixture. This is vital for optimal combustion efficiency.

Air and Oil Systems

Within the Air Outlet Assembly Pipe and the Arrangement, Oil Fill, the Spring Washer prevents leaks by providing additional pressure against sealing surfaces. This ensures that air and oil systems operate without contamination or loss of pressure.

Reservoir and Filter Systems

In the Assembly Reservoir and the Filter Shell and Gas Mixers, the Spring Washer plays a role in maintaining the structural integrity of connections, ensuring that fluids and gases are contained effectively within the system.

Engine Control and Electronic Systems

For the Control Operating Engine and the Electronic Control Engine, the Spring Washer is used in various connectors and mounts. It helps in securing electronic components, ensuring that connections remain stable under varying engine conditions.

Engine Assembly and Module Systems

In the Engine Assembly Cover and the Engine Control Module, the Spring Washer is critical in maintaining the tightness of screws and bolts. This is important for the structural integrity and electrical connections within the engine assembly.

Lubrication and Fuel Systems

The Lubricating Oil Filter Housing and the Module, Fuel Control benefit from the Spring Washer by ensuring that connections in the lubrication and fuel pathways are secure, preventing leaks and ensuring consistent flow.

Turbocharger and Ignition Systems

In the Plumbing, Turbocharger and the System Ignition, the Spring Washer ensures that high-pressure connections remain intact, which is essential for the performance and safety of these systems.

Timing and Water Systems

Finally, in the Timing Mounting Indicator and the Water Outlet Connection, the Spring Washer helps in maintaining the precision of timing components and the integrity of coolant pathways, respectively.

Overall, the part 3420854 Spring Washer is a small yet significant component that enhances the reliability and performance of various engine systems by ensuring secure and leak-free connections.

Conclusion

The Cummins Part #3420854 Spring Washer is a critical component in both commercial truck operations and various engine systems. Its role in maintaining consistent bolt tension, preventing loosening, and enhancing the reliability of bolted connections is indispensable. Proper installation, regular maintenance, and timely replacement of this part are essential practices to ensure the optimal performance and safety of truck and engine systems.

-

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

Hiereth, Hermann, Peter Prenninger, and Klaus W Drexl. Charging the Internal Combustion Engine. Springer, 2010.

↩ -

Robinson, Alan, and Andrew Livesey. The Repair of Vehicle Bodies Fifth Edition. Elsevier, 2006.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.