This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Part #3633027 Spring is a component utilized in commercial trucks, contributing to the vehicle’s operational efficiency. This spring is integral to the truck’s suspension system, playing a role in load handling and ride comfort. Understanding its function and importance can enhance the overall maintenance and performance of commercial trucks.

Basic Concepts of Springs in Automotive Applications

Springs in automotive applications serve to absorb and dampen the shocks and vibrations encountered during vehicle operation. They are fundamental to the suspension system, ensuring a stable and comfortable ride. In trucks, various types of springs are employed, including coil springs, leaf springs, and torsion bars. Each type operates on the principle of storing mechanical energy when compressed or extended and releasing it to maintain vehicle stability and support the load 1.

Purpose of the 3633027 Spring in Truck Operation

This Cummins part is designed to work within the truck’s suspension system, specifically aiding in the absorption of road irregularities. It interacts with other suspension components, such as shock absorbers and axles, to provide a balanced and smooth ride. This spring contributes to the truck’s performance by ensuring even weight distribution and maintaining tire contact with the road, which is vital for safety and efficiency 2.

Key Features of the 3633027 Spring

This part is characterized by its robust design and construction. It is typically made from high-strength steel, which allows it to withstand the significant stresses and loads encountered in commercial truck operations. The coil configuration of the spring is meticulously engineered to provide the necessary flexibility and strength. Additionally, the spring may feature unique attributes such as corrosion-resistant coatings or specialized end treatments to enhance its durability and functionality 3.

Benefits of Using the 3633027 Spring

Utilizing this part offers several advantages. It provides improved load handling capabilities, allowing trucks to carry heavier payloads without compromising ride comfort. The spring’s design contributes to enhanced ride comfort by effectively absorbing road shocks. Furthermore, its high-strength material and construction result in increased durability, reducing the frequency of replacements and maintenance costs.

Installation and Integration

Proper installation of this part is crucial for its effective operation. The process involves preparatory steps such as ensuring the suspension system is clean and free of debris. Tools required may include spring compressors and wrenches. Integration with other truck components, such as the axle and shock absorbers, must be precise to ensure the spring functions as intended within the suspension system.

Troubleshooting Common Issues

Common issues associated with spring failures or malfunctions can include excessive wear, corrosion, or damage from road debris. Diagnostic methods involve visual inspections for signs of wear or deformation and functional tests to assess the spring’s ability to absorb shocks. Recommended solutions may range from cleaning and lubricating the spring to replacement if significant damage is detected.

Maintenance Tips

Routine maintenance practices are vital to ensure the longevity and optimal performance of the 3633027 Spring. Inspection intervals should be established based on the truck’s usage and operating conditions. Care procedures may include cleaning the spring to remove dirt and debris, checking for signs of wear or corrosion, and ensuring all mounting points and connections are secure.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to excellence is reflected in its extensive product range, which includes engines, powertrain components, and aftermarket parts designed to meet the demanding requirements of commercial vehicles.

Spring Part 3633027 Compatibility with Cummins Engines

This part, manufactured by Cummins, is designed to fit a range of Cummins engines, ensuring reliable performance and durability across various applications. This part is integral to the operation of these engines, providing essential support and functionality.

QSK45 CM500 and QSK60 CM500 Engines

This part is compatible with the QSK45 CM500 and QSK60 CM500 engines. These engines are known for their robust design and high performance, often used in heavy-duty applications. The spring ensures that the engine components operate smoothly, maintaining efficiency and longevity.

QSK60 CM850 MCRS and QSK60G Engines

For the QSK60 CM850 MCRS and QSK60G engines, this part is equally crucial. These engines are designed for demanding environments, and the spring plays a key role in the mechanical integrity of the engine, ensuring that it can handle the stresses of continuous operation.

QSK78 CM500 and QSK95 CM2350 K111/K113 Engines

This part also fits the QSK78 CM500 and QSK95 CM2350 K111/K113 engines. These engines are part of Cummins’ lineup of high-power, high-efficiency engines, often used in critical applications where reliability and performance are paramount. The spring’s role in these engines is to maintain the precise alignment and operation of various components, contributing to the overall efficiency and durability of the engine.

This part is a critical component that ensures the smooth and efficient operation of these Cummins engines, highlighting the importance of using genuine Cummins parts for maintenance and repairs.

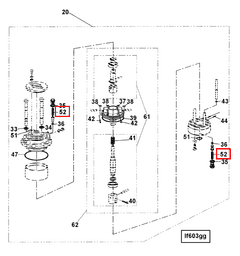

Role of Part 3633027 Spring in Engine Systems

In the context of engine systems, this part plays a significant role in ensuring the efficient operation of various components. Specifically, it is integral to the functionality of the full flow oil filter, lubricating oil filter, and lubricating oil filter head.

Full Flow Oil Filter

The full flow oil filter is designed to remove contaminants from the engine oil as it circulates through the system. This part assists in maintaining the structural integrity of the filter, ensuring that it can withstand the pressure of the oil flow without deformation. This helps in consistent filtration efficiency, which is essential for protecting engine components from wear and tear.

Lubricating Oil Filter

In the lubricating oil filter, this part contributes to the filter’s ability to capture particles and impurities from the lubricating oil. By providing necessary tension and support, the spring ensures that the filter media remains taut and effective. This is particularly important in high-performance engines where the quality of lubrication directly impacts engine longevity and performance.

Lubricating Oil Filter Head

The lubricating oil filter head is a critical component that houses the filter media and connects to the engine’s oil passages. This part is used within this assembly to help seal the filter media securely in place. This sealing is vital for preventing oil leaks and ensuring that all oil passing through the system is properly filtered. The spring’s role in maintaining this seal under varying pressure conditions cannot be overstated.

Lubricating Oil Filter Kit

When considering the lubricating oil filter kit, which typically includes the filter, head, and associated gaskets and seals, this part is often a key component. It ensures that all elements of the kit function cohesively, providing a reliable filtration system that enhances the overall performance and reliability of the engine.

Conclusion

In summary, this part is an essential component in the effective operation of oil filtration systems within engine assemblies. Its role in maintaining structural integrity, ensuring proper sealing, and supporting filtration efficiency underscores its importance in engine maintenance and performance.

-

Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines, Hua Zhao, CRC Press, 2010

↩ -

Diesel Engine Management Systems and Components, Konrad Reif Ed, Springer Vieweg, 2014

↩ -

Heavy-Duty Wheeled Vehicles, Haoran Hu, Rudy Smaling, and Simon Baseley, SAE International, 2014

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.